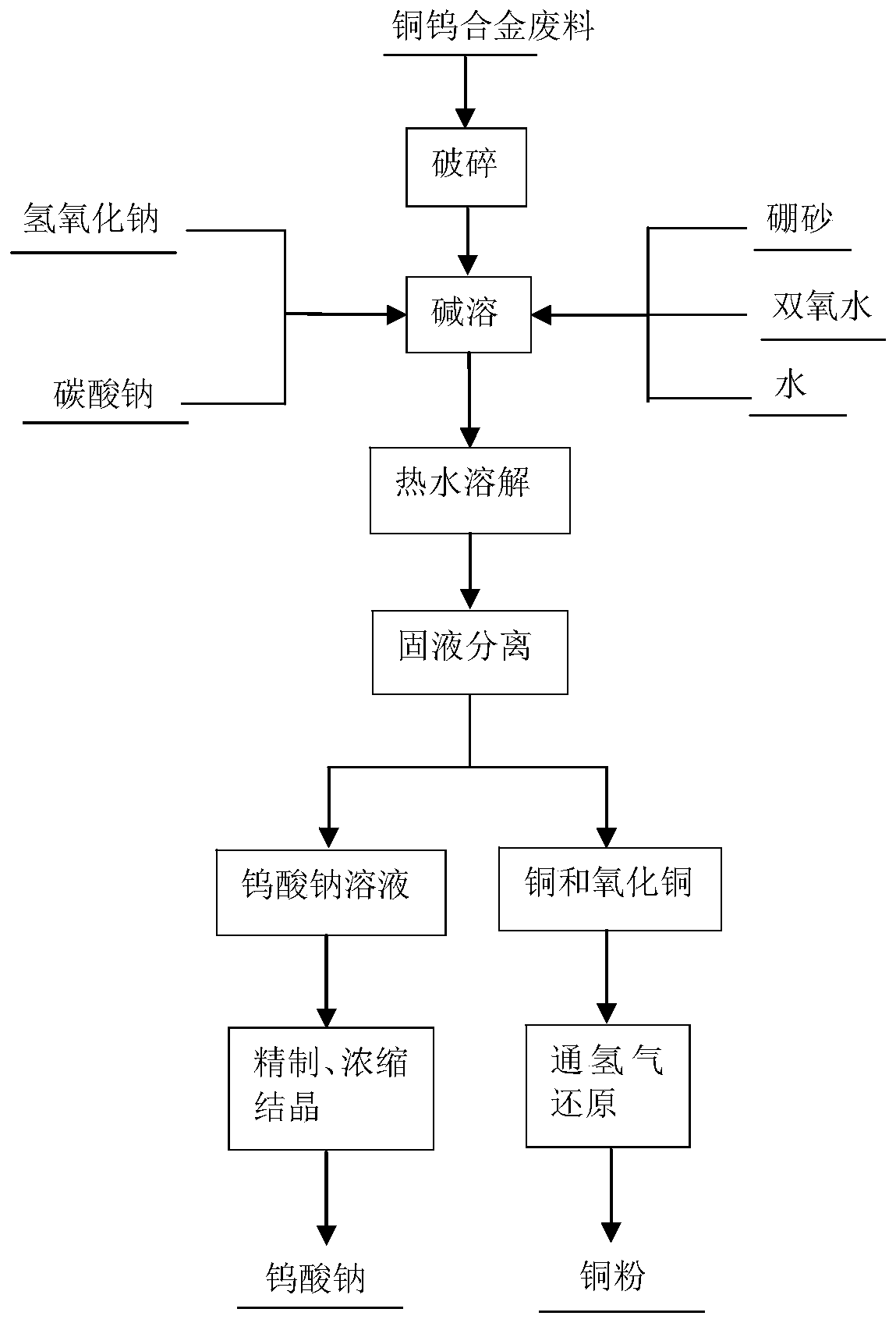

Method for efficiently recovering copper and tungsten from copper and tungsten alloy waste

A technology of copper-tungsten alloy and copper recovery, which is applied in the direction of improving process efficiency, etc., can solve the problems of difficult to handle nitrogen oxides and low efficiency, and achieve significant economic benefits, simple process route, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1000g copper-tungsten alloy, containing 22% copper, 68% tungsten, and 10% carbon, crush the alloy, mix it with 136g sodium hydroxide, 680g sodium carbonate, and 6.8g borax, add a small amount of water, heat up to 300°C, and dissolve the material In a molten state, slowly drop 680g of hydrogen peroxide. After the reaction is complete, the material solidifies. Add an appropriate amount of hot water to dissolve the material, and separate the solid and liquid through vacuum filtration. The sodium tungstate solution was refined, concentrated and crystallized to obtain 1208g of qualified sodium tungstate product, the recovery rate was 99%, and the tested purity was 99.1%. Copper oxide was reduced by passing hydrogen gas to obtain 218.5 g of copper powder with a recovery rate of 99.3% and a purity of 99.2% after testing.

Embodiment 2

[0025] Take 5000g of copper-tungsten alloy, containing 30% copper, 65% tungsten, and 5% carbon, crush the alloy, mix it with 650g sodium hydroxide, 3250g sodium carbonate, and 32g borax, add a small amount of water, heat up to 400°C, and the material dissolves into a In the molten state, slowly drop 4000g of hydrogen peroxide. After the reaction is completed, the material solidifies, and an appropriate amount of hot water is added to dissolve the material, and the solid and liquid are separated by vacuum filtration. The sodium tungstate solution was refined, concentrated and crystallized to obtain 5810g of qualified sodium tungstate product, the recovery rate was 99.6%, and the tested purity was 99.2%. Copper oxide was reduced by passing hydrogen gas to obtain 1488g of copper powder, the recovery rate was 99.2%, and the purity was 99.5% after testing.

Embodiment 3

[0027] Take 10,000g copper-tungsten alloy, containing 40% copper, 52% tungsten, and 8% carbon, crush the alloy, mix evenly with 1040g sodium hydroxide, 5200g sodium carbonate, and 52g borax, add a small amount of water, heat up to 500°C, and the material dissolves into a In the molten state, slowly drop 9000g of hydrogen peroxide. After the reaction is complete, the material solidifies. Add an appropriate amount of hot water to dissolve the material, and separate the solid and liquid through vacuum filtration. The sodium tungstate solution was refined, concentrated and crystallized to obtain 9274g of qualified sodium tungstate product, the recovery rate was 99.4%, and the tested purity was 99.5%. Copper oxide was reduced by passing hydrogen gas to obtain 3980 g of copper powder, the recovery rate was 99.5%, and the purity was 99.6% after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com