Granulation-free fermentation feed for penaeus orientalis

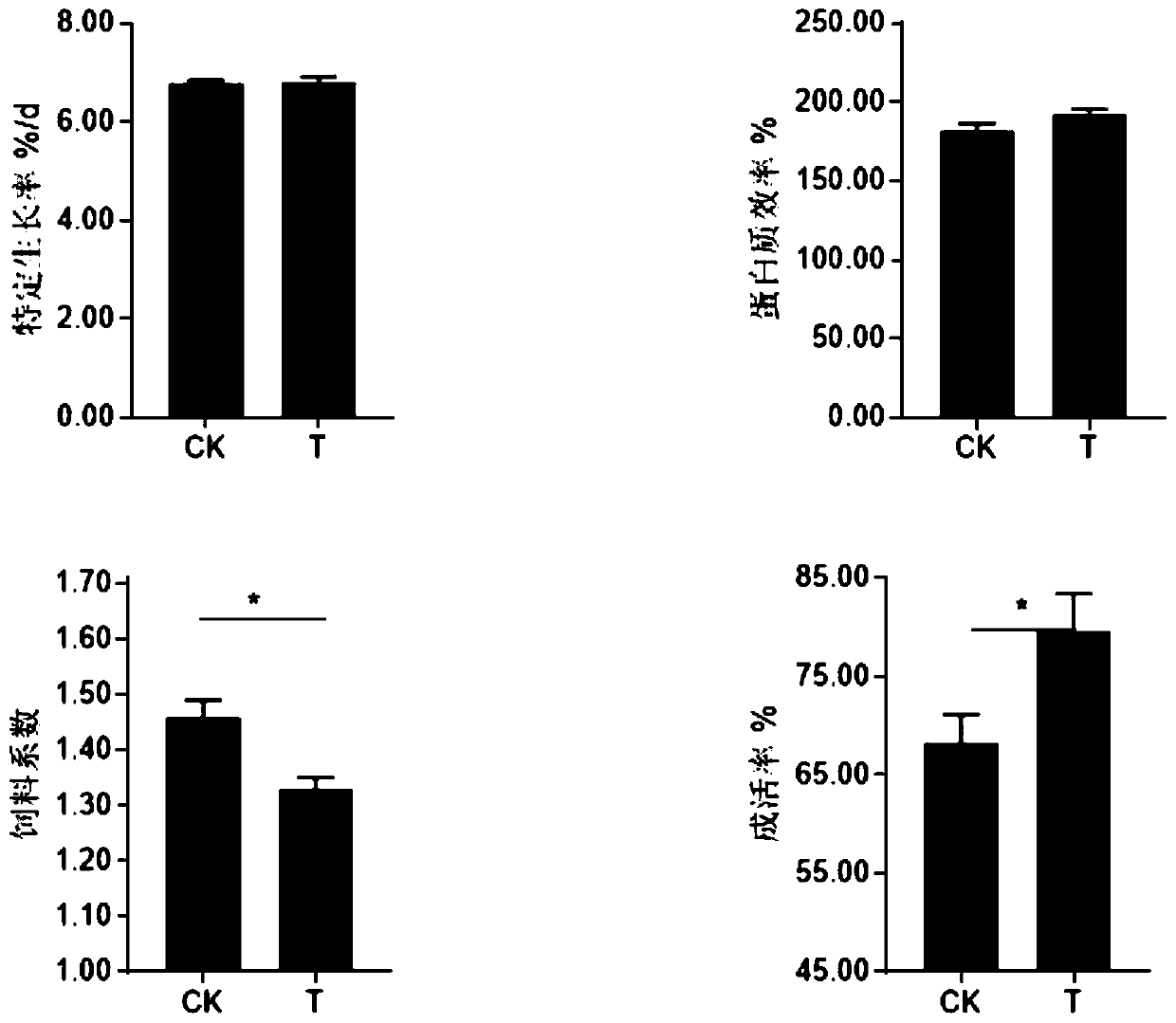

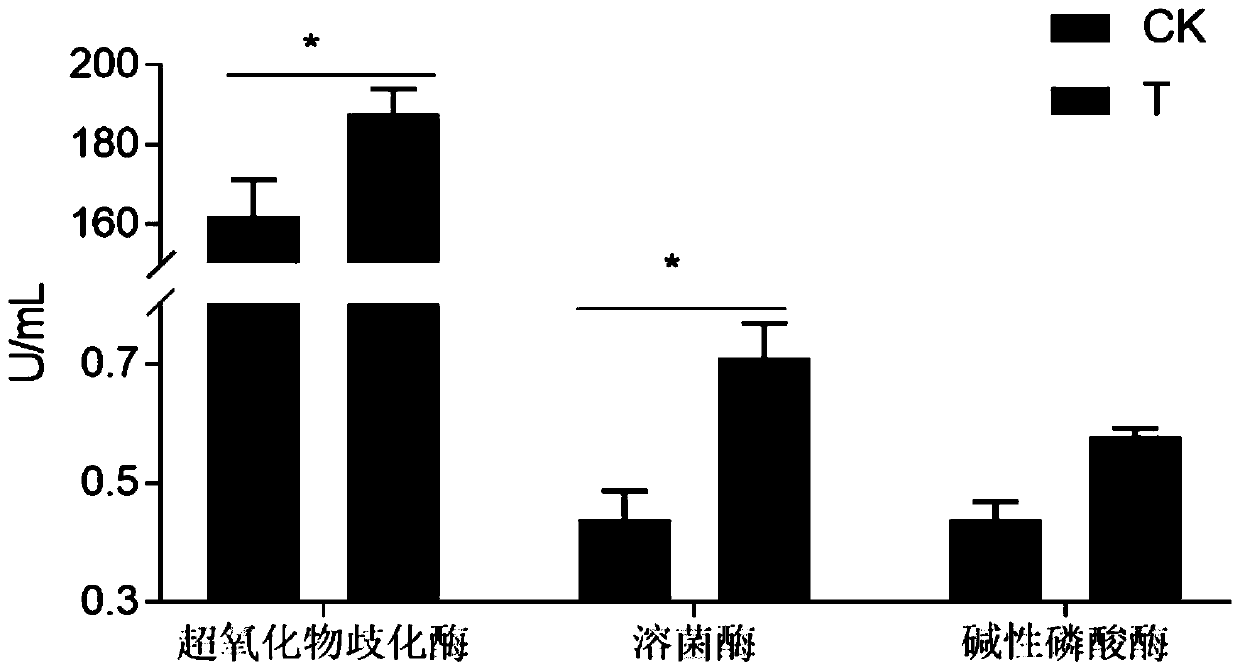

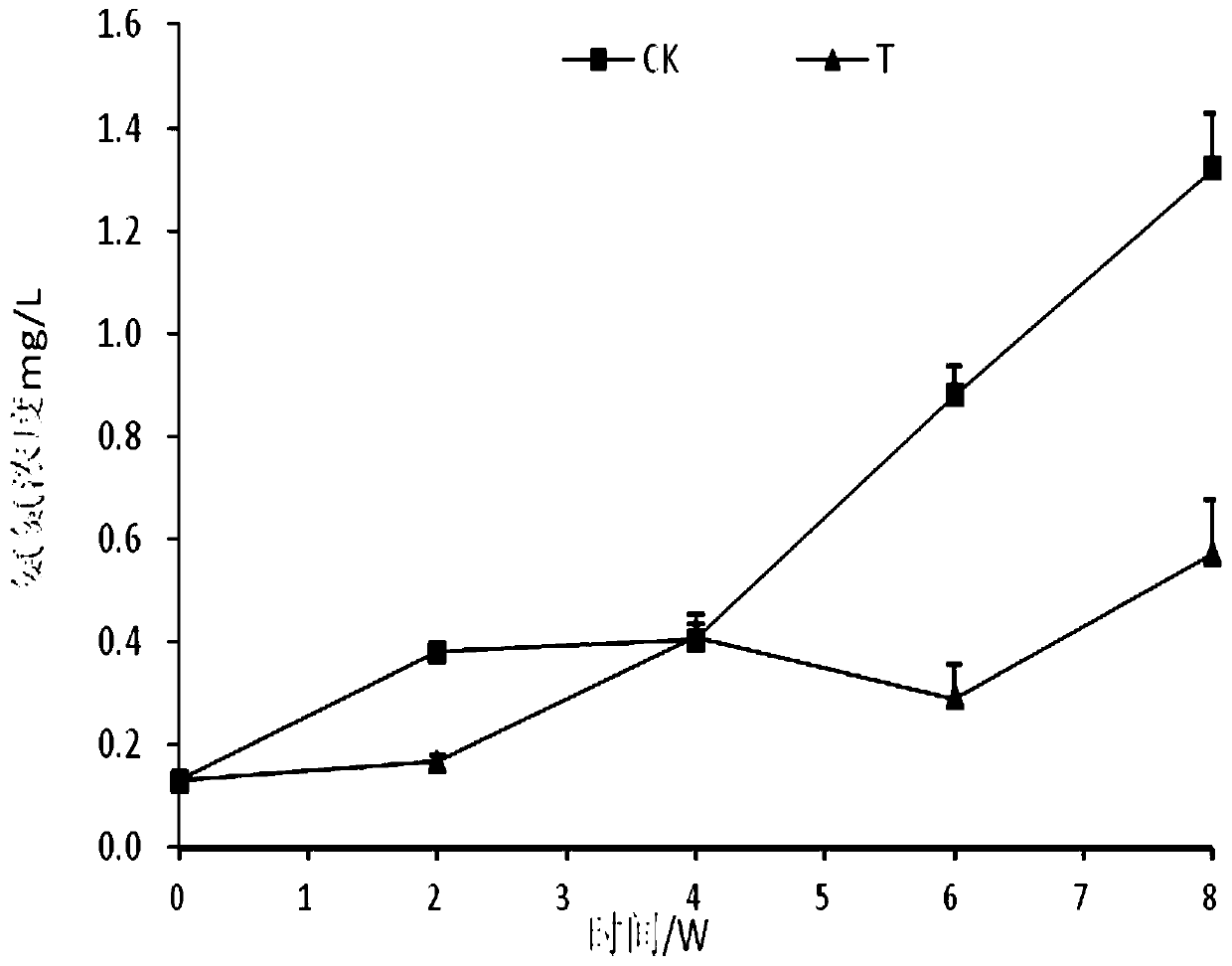

A technology for fermenting feed and prawns, applied to animal feed, animal feed, bacteria used in food preparation, etc., can solve the problem that aerobic bacteria do not fully play the role of bacteria, the quality of fermented products cannot be guaranteed, and pathogenic bacteria Or the increase of harmful bacteria and other problems, to achieve the effect of enhancing immunity, improving the structure of microbial flora, and reducing the feed coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of fermentation strain

[0032] Prepare Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, and Enterococcus faecalis seed liquid, and the number of viable bacteria is 1.0×10 9 More than cfu / mL;

[0033] a. Preparation of Bacillus subtilis seed liquid

[0034] Pick Bacillus subtilis and inoculate it into LB medium, and activate it on a shaking table at 37°C for 16 hours; then inoculate the activated bacterial liquid into the primary seed medium according to the mass ratio of 3% inoculum, and cultivate it on a shaking table at 37°C for 24 hours to obtain Bacillus subtilis seed liquid. The primary seed culture medium is: by mass fraction, including glucose 0.5%, cornstarch 1.5%, soybean meal 2%, yeast powder 0.5%, magnesium sulfate 0.2%, dipotassium hydrogen phosphate 0.2%, manganese sulfate, 0.03%, calcium carbonate 0.24%, the balance is water, pH7.0±0.2, and its preparation method is to mix the above-mentioned ingredients uniformly, ...

Embodiment 2

[0049] (1) Preparation of fermentation strain (same as Example 1)

[0050] Prepare Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, and Enterococcus faecalis seed liquid, and the number of viable bacteria is 1.0×10 9 More than cfu / mL;

[0051] 2. Crushing, grading, sieving and mixing of fermented feed raw materials: crushing feed raw materials corn and soybeans to obtain crushed corn and soybeans respectively, and grading and sieving to obtain particles with a particle size of 0.5-0.9mm. Then take by weighing according to the following weight ratio: 20% of crushed corn, 40% of crushed soybeans, 20% of fish meal, 19% of bran, 1% of prawn premixed feed, add water until the moisture content is 40%, and mix evenly with a mixer to obtain solid media.

[0052] 3. Cooking and sterilizing solid medium, air cooling

[0053] The above-prepared solid medium was sterilized by high-temperature cooking at 121°C for 30 minutes, and cooled by an air cooler at 34°C for ...

Embodiment 3

[0063] 1, the preparation of fermentation strain (with embodiment 1)

[0064] Prepare Bacillus subtilis, Saccharomyces cerevisiae, Lactobacillus plantarum, and Enterococcus faecalis seed liquid, and the number of viable bacteria is 1.0×10 9 cfu / mL or more.

[0065] 2. Crushing, grading, sieving and mixing of fermented feed raw materials: crushing feed raw materials corn and soybeans to obtain crushed corn and soybeans respectively, and grading and sieving to obtain particles with a particle size of 0.5-0.9mm. Then take by weighing according to the following weight proportions: 26% of crushed corn, 32% of soybean crush, 20% of fish meal, 21.5% of bran, 0.5% of prawn premixed feed, add water until the moisture content is 40%, and mix evenly with a mixer to obtain solid media.

[0066] 3. Cooking and sterilizing solid medium, air cooling

[0067] The above-prepared solid medium was sterilized by high-temperature cooking at 121°C for 30 minutes, and cooled by an air cooler at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bottom area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com