A ruthenium-modified sulfur-doped graphene two-dimensional material and its preparation and application

A technology of sulfur-doped graphene and two-dimensional materials, applied in the field of two-dimensional materials, can solve the problems of poor stability, reduced catalytic efficiency of catalysts, complicated preparation methods of electrode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

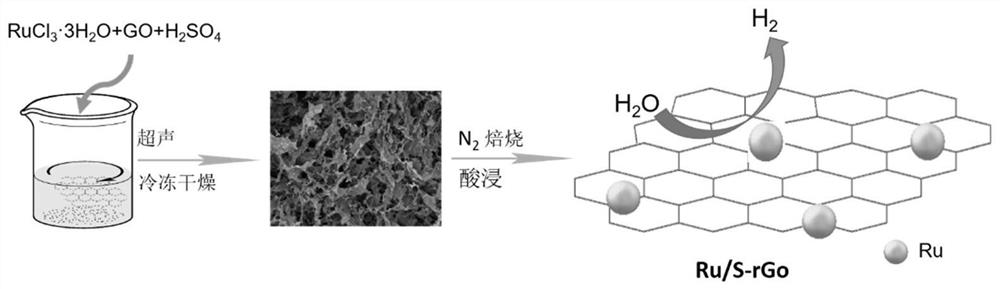

[0059] Weigh 5mg RuCl 3 ·6H 2 O and 20 mg of graphene oxide were added to 10 mL of deionized water, and the pH value of the solution was adjusted to 2 by sulfuric acid, and ultrasonically oscillated for 4 hours, so that the two substances were evenly dispersed in the solution. The solution was lyophilized to remove solvent. The resulting solid was heated at 5 °C min under nitrogen atmosphere -1 The heating rate was added to 700°C, and baked for 2 hours. After cooling to room temperature, soak it with 0.1mol / L hydrochloric acid for 5 hours. Finally, the solid was washed with water until neutral, and dried in vacuum to obtain a sulfur-doped graphene two-dimensional material decorated with ruthenium.

Embodiment 2

[0061] Weigh 2.5mg RuCl 3 ·6H 2 O and 20 mg of graphene oxide were added to 10 mL of deionized water, and the pH value of the solution was adjusted to 3 by sulfuric acid, and ultrasonically oscillated for 3 hours, so that the two substances were evenly dispersed in the solution. The solution was lyophilized to remove solvent. The resulting solid was heated at 10 °C min under an argon atmosphere. -1 The heating rate was added to 600°C and fired for 1.5 hours. After cooling to room temperature, soak it with 0.05mol / L hydrochloric acid for 3 hours. Finally, the solid was washed with water until neutral, and dried in vacuum to obtain a sulfur-doped graphene two-dimensional material decorated with ruthenium.

Embodiment 3

[0063] Weigh 10mg RuCl 3 ·6H 2 O and 20 mg of graphene oxide were added to 10 mL of deionized water, the pH value of the solution was adjusted to 1 by sulfuric acid, and ultrasonic vibration was performed for 6 hours, so that the two substances were evenly dispersed in the solution. The solution was lyophilized to remove solvent. The resulting solid was heated at 3 °C min under a nitrogen atmosphere. -1 The heating rate was added to 800°C and fired for 3 hours. After cooling to room temperature, soak it with 0.8mol / L hydrochloric acid for 8 hours. Finally, the solid was washed with water until neutral, and dried in vacuum to obtain a sulfur-doped graphene two-dimensional material decorated with ruthenium.

[0064] The test results of embodiment 1, embodiment 2 and embodiment 3 are as follows:

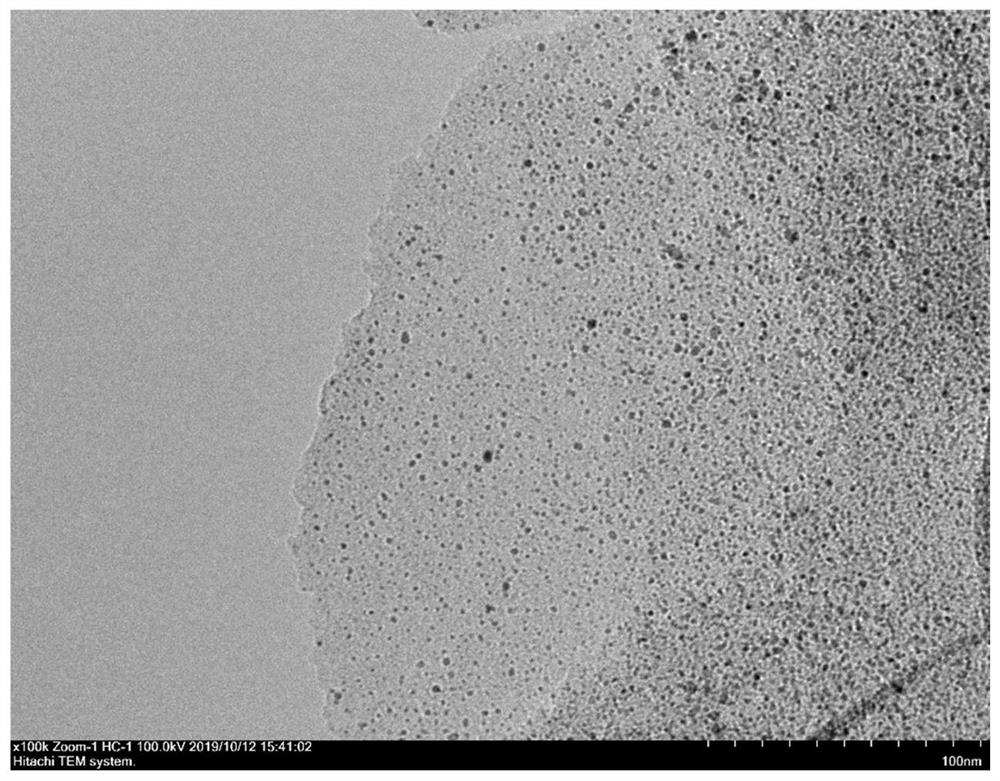

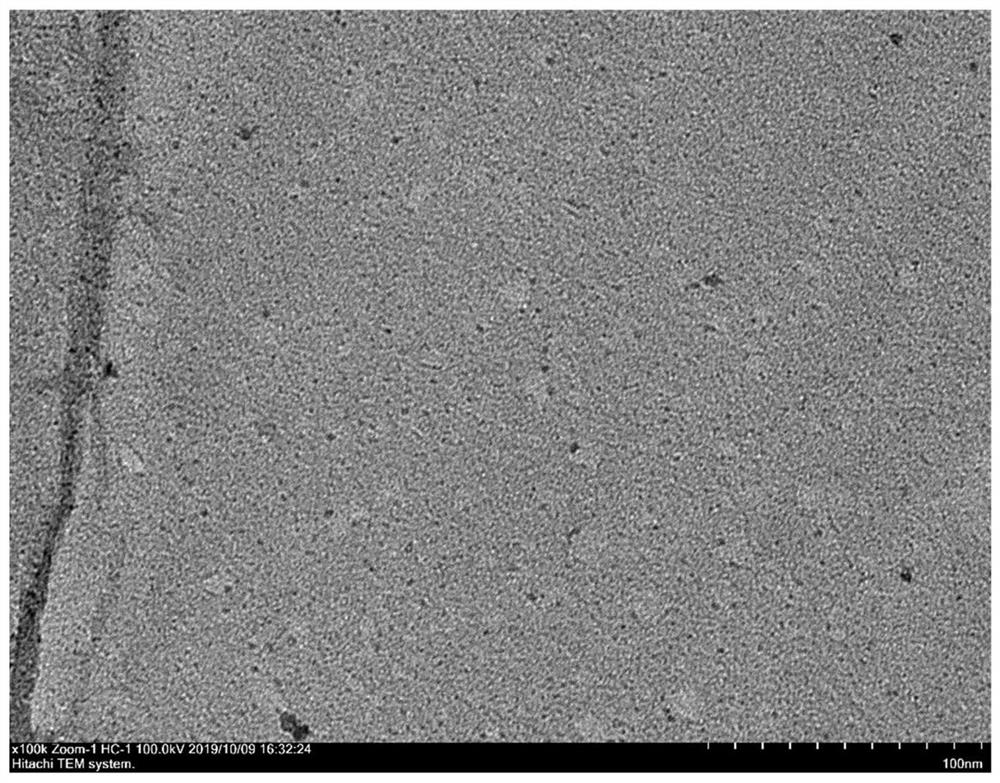

[0065] (1) SEM and TEM test results show that: the prepared composite material has a unique two-dimensional structure, and crystalline nanoparticles of elemental ruthenium can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com