Carbene iridium catalyst and preparation method and application thereof

A catalyst, carbene iridium technology, applied in the field of carbene iridium catalyst preparation, can solve the problems of high energy consumption, easy precipitation and deactivation of metal iridium, equipment corrosion, etc., achieves good reaction stability, solves the problem of long production process route and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 prepares carbene iridium catalyst

[0049] In the glove box, accurately measure 0.2006g CAAC ligand, 0.1097g KHMDS and 0.1678g [Ir(COD)Cl] 2 Place in a 100 mL Shrek bottle, place the Shrek bottle in a Dewar bottle, and replace the reaction system with nitrogen. Then, add 100mL of acetone to the Dewar bottle, and then add liquid nitrogen to the acetone until the acetone is frozen into ice. At this time, the temperature of the reaction system drops to -78°C, and slowly add about 40mL of tetrahydrofuran after dehydration to the Shrek bottle. . After the reaction system returned to room temperature naturally, it was reacted overnight to obtain the crude product of CAAC-IrCl(COD).

[0050] Dissolve the crude CAAC-IrCl(COD) with a small amount of dichloromethane, then filter the desalinated product with diatomaceous earth, and then purify the desalted crude CAAC-IrCl(COD) with a silica gel column, benzene:n-hexane=1:1 As an eluent, after rotary evaporation and...

Embodiment 2

[0052] Embodiment 2 prepares carbene iridium catalyst

[0053] In the glove box, accurately measure 0.4012g CAAC ligand, 0.2194g KHMDS and 0.3356g [Ir(COD)Cl] 2 Place in a 100 mL Shrek bottle, place the Shrek bottle in a Dewar bottle, and replace the reaction system with nitrogen. Then, add 100mL of acetone to the Dewar bottle, and then add liquid nitrogen to the acetone until the acetone is frozen into ice. At this time, the temperature of the reaction system drops to -78°C, and slowly add about 50mL of tetrahydrofuran after dehydration to the Shrek bottle. . After the reaction system returned to room temperature naturally, it was reacted overnight to obtain the crude product of CAAC-IrCl(COD).

[0054] Dissolve the crude CAAC-IrCl(COD) with a small amount of dichloromethane, then filter the desalinated product with diatomaceous earth, and then purify the desalted crude CAAC-IrCl(COD) with a silica gel column, benzene:n-hexane=1:1 As an eluent, after rotary evaporation and...

Embodiment 3

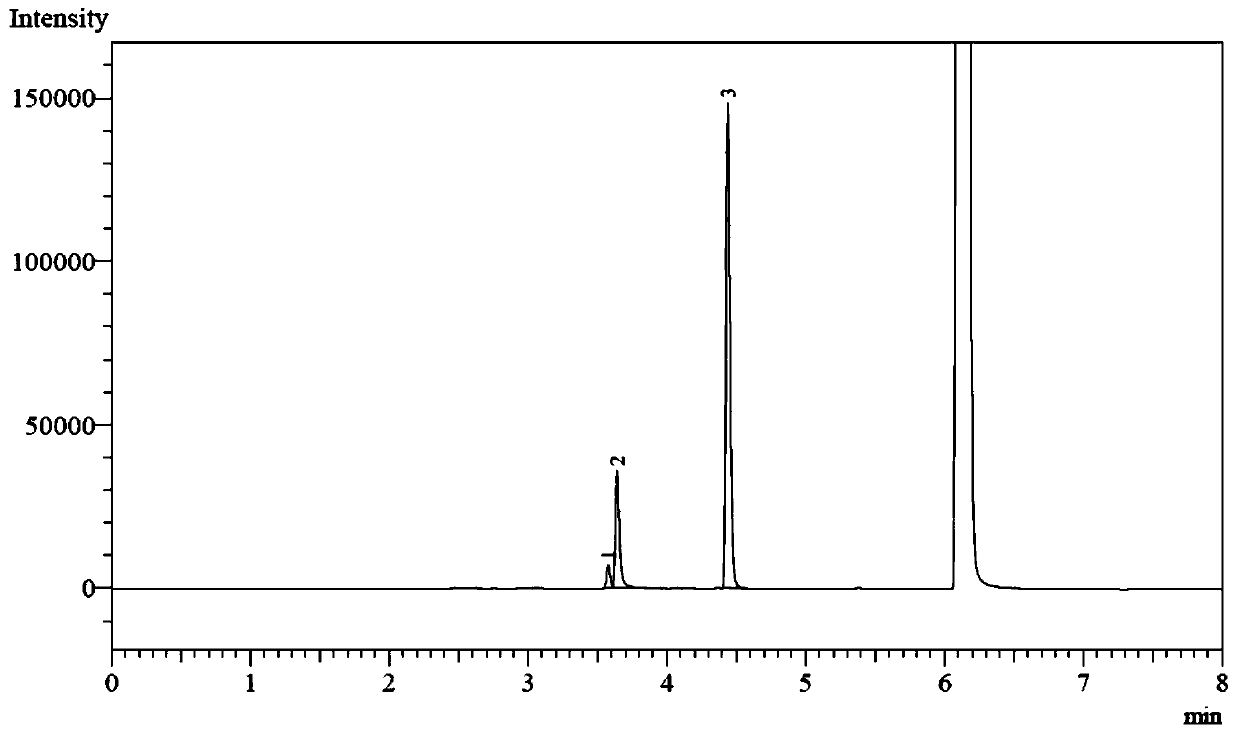

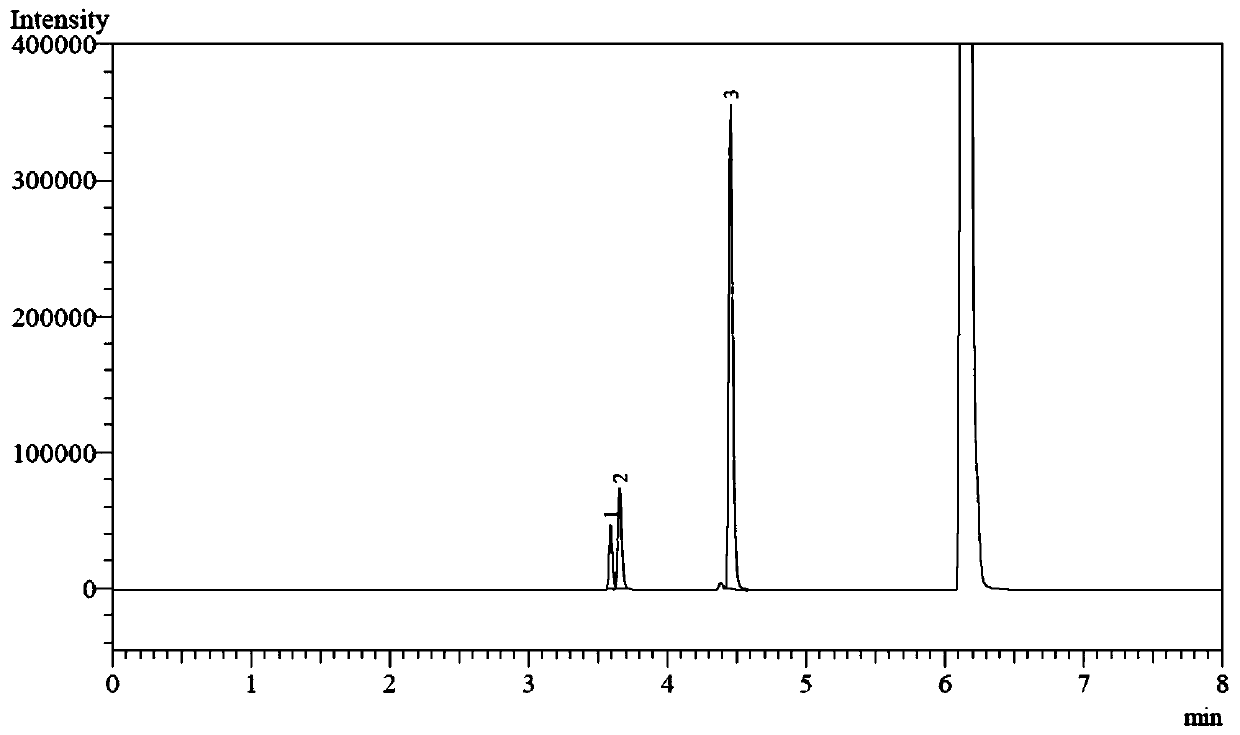

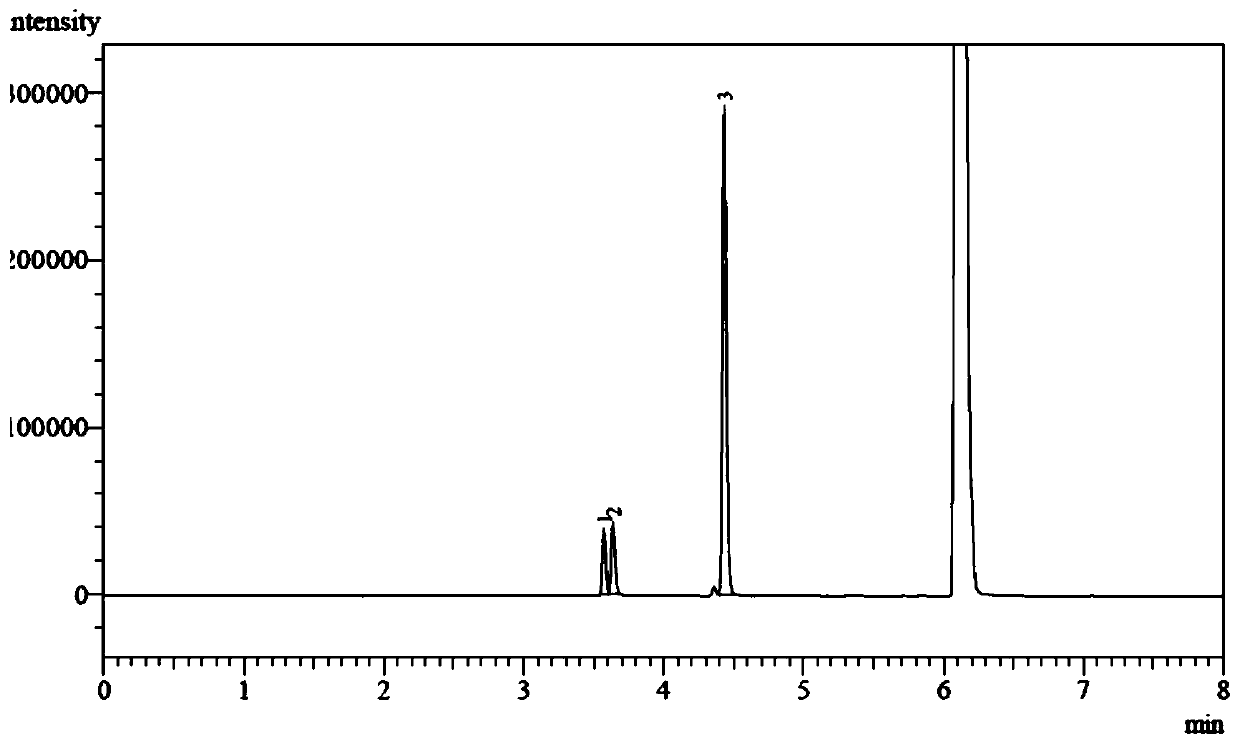

[0056] Embodiment 3 methanol carbonylation prepares methyl acetate

[0057] Take by weighing the CAAC-IrCl (COD) 80mg of embodiment 1 and place in the autoclave, add methanol 5mL therein, iodomethane 0.2mL, pass into CO replacement 3 times, make the pressure in the reaction system reach 2.0MPa, at a temperature of React at 120°C for 20 hours, stir with magnetic force at a stirring speed of 500 rpm, and the total pressure of the system at this time is about 2.5 MPa. After the reaction, the autoclave was cooled to room temperature.

[0058] Analyzed by gas chromatography, see figure 1 , the conversion rate of methanol is 81%, and the selectivity of methyl acetate is as high as 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com