Diamine compound as well as preparation method and application thereof

A technology of amine compounds and compounds, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problem of prolonging the film forming time, reducing the film thickness of slurry, and vitrification of polyimide flexible substrates. Problems such as transition temperature, heat resistance, dimensional stability and mechanical properties decrease, to achieve the effect of improving stability and ensuring heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

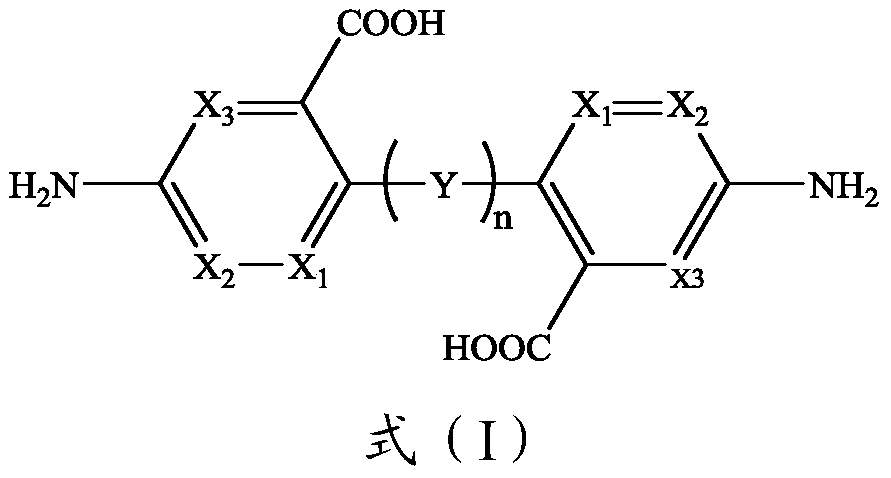

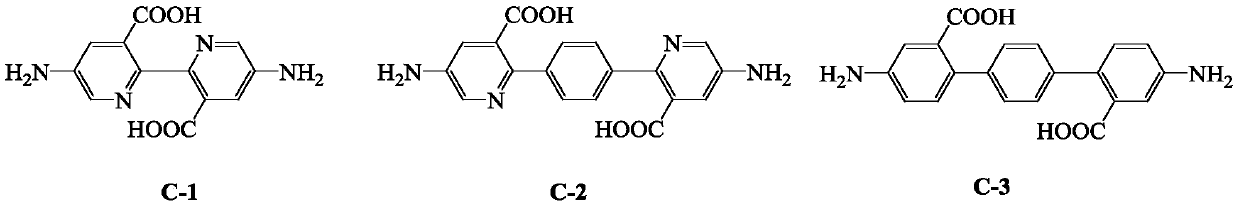

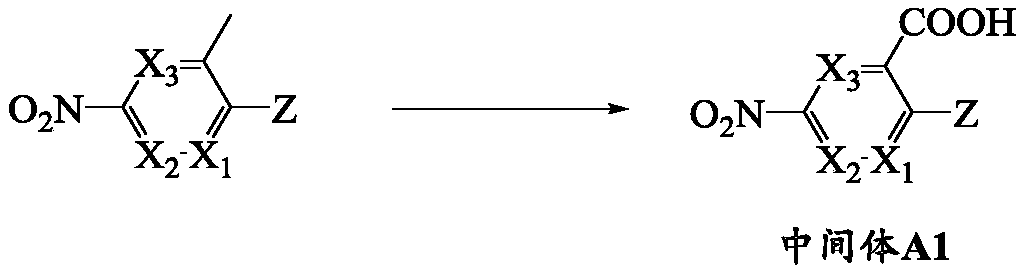

[0053] Based on the same inventive concept, the embodiment of the present invention also provides a preparation method of the above-mentioned diamine compound, comprising: the following steps represented by [chemical reaction formula 1] to [chemical reaction formula 4]:

[0054] Will Carry out oxidation, obtain intermediate A1; Intermediate A1 and Carry out coupling, obtain intermediate A2; Intermediate A2 and or Z-Y-Z coupling to obtain intermediate A3; reduction of intermediate A3 to obtain a diamine compound;

[0055] [Chemical Reaction Formula 1]

[0056]

[0057] Optionally, The specific process of oxidation is: And chromium trioxide, add concentrated sulfuric acid solvent to react.

[0058] [Chemical Reaction Formula 2]

[0059]

[0060] Optionally, intermediate A1 is combined with The specific process of coupling is: intermediate A1 and Pinacol diboronic acid, potassium acetate and 1,1'-bis(diphenylphosphino)ferrocene]palladium dichloride are added i...

Embodiment 1

[0163] Add 5.33g of diamine compound B-1 and 95g of N-methylpyrrolidone into a 1L reaction flask, turn on the mechanical stirring, replace the air in the flask with nitrogen, and place the system in an ice-water bath after all the monomers are dissolved , add A-2 13.97g in batches to the above mixed solution, control the reaction temperature not to exceed 15°C, after the addition is complete, the whole reaction is stirred at room temperature for 3h, then continue to add A-2 0.73g and C-10.71g in turn, at room temperature Stirring was continued for 18 hours to obtain a polyamic acid solution (PAA-1) with a mass concentration of 18%. The viscosity of the polyamic acid solution at 25° C. was tested to be 5100 mPa·s.

Embodiment 2

[0165] Add 5.39g of diamine compound B-1 and 94g of N-methylpyrrolidone into a 1L reaction flask, turn on the mechanical stirring, replace the air in the flask with nitrogen, and place the system in an ice-water bath after all the monomers are dissolved , add A-2 14.26g in batches to the above mixed solution, control the reaction temperature not to exceed 15°C, after the addition is complete, the whole reaction is stirred at room temperature for 3h, then continue to add A-2 0.44g and C-20.54g in turn, at room temperature Stirring was continued for 18 hours to obtain a polyamic acid solution (PAA-2) with a mass concentration of 18%. The viscosity of the polyamic acid solution at 25° C. was tested to be 6550 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com