Polyaryletherketone polymer synthesis method, PAEK film, PAEK-Al2O3 composite film preparation method and application

A technology of polyaryletherketone and synthesis method, which is applied in the field of preparation of lithium-ion battery separators, can solve the problems of easy swelling and low mechanical strength, and achieve the effects of good affinity, enhanced thermal stability, and enhanced chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

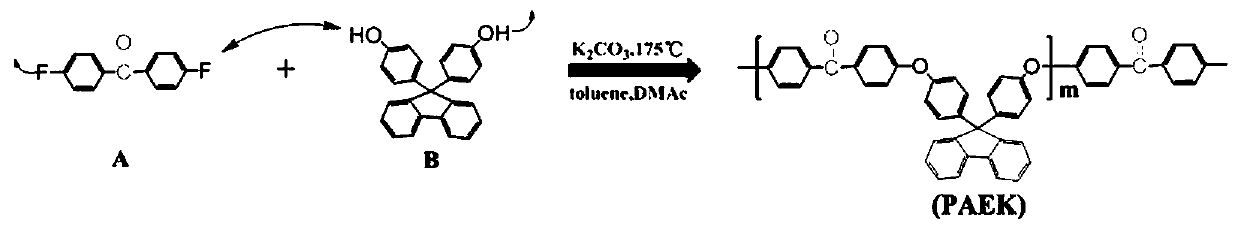

[0038] see figure 1 , The present invention proposes a synthetic method of heat-resistant polyaryletherketone polymer (i.e. PAEK polymer), comprising the following steps:

[0039] Step 1: Install a three-necked flask with a reflux device and a water separator on the magnetic stirrer, and place the flask in an oil bath;

[0040] Step 2: Add 0.6546 g of 4,4′-difluorobenzophenone, 1.0512 g of bisphenol fluorene, 0.828 g of potassium carbonate, 10 ml of N,N-dimethylacetamide solution and 10 ml of Toluene solution;

[0041] Step 3: Slowly ramp up to 140 o C, and reflux at constant temperature for 4h, then raise the temperature to 175 o C, react for 5 h;

[0042] Step 4: Cool to room temperature to obtain a viscous solid, soak the viscous solid in methanol aqueous solution to clean the residual organic solvent, add dropwise to hydrochloric acid aqueous solution to obtain a precipitate, and filter;

[0043] Step 5: Solid at 110 o C was dried in a vacuum oven for 24 h to obtain ...

Embodiment 1

[0055] Step 1: Install a three-necked flask with a reflux device and a water separator on the magnetic stirrer, and place the flask in an oil bath;

[0056] Step 2: Add 0.6546 g of 4,4′-difluorobenzophenone, 1.0512 g of bisphenol fluorene, 0.828 g of potassium carbonate, 10 ml of N,N-dimethylacetamide solution and 10 ml of toluene solution ;

[0057] Step 3: Slowly ramp up to 140 o C, and reflux at constant temperature for 4h, then raise the temperature to 175 o C, react for 5 h; Step 4: Cool to room temperature to obtain a viscous solid, soak the viscous solid in methanol aqueous solution to clean the residual organic solvent, add dropwise to hydrochloric acid aqueous solution to obtain a precipitate, and filter.

[0058] Step 5: Solid at 110 o C was dried in a vacuum oven for 24 h to obtain a polyaryletherketone polymer with a yield of 96%.

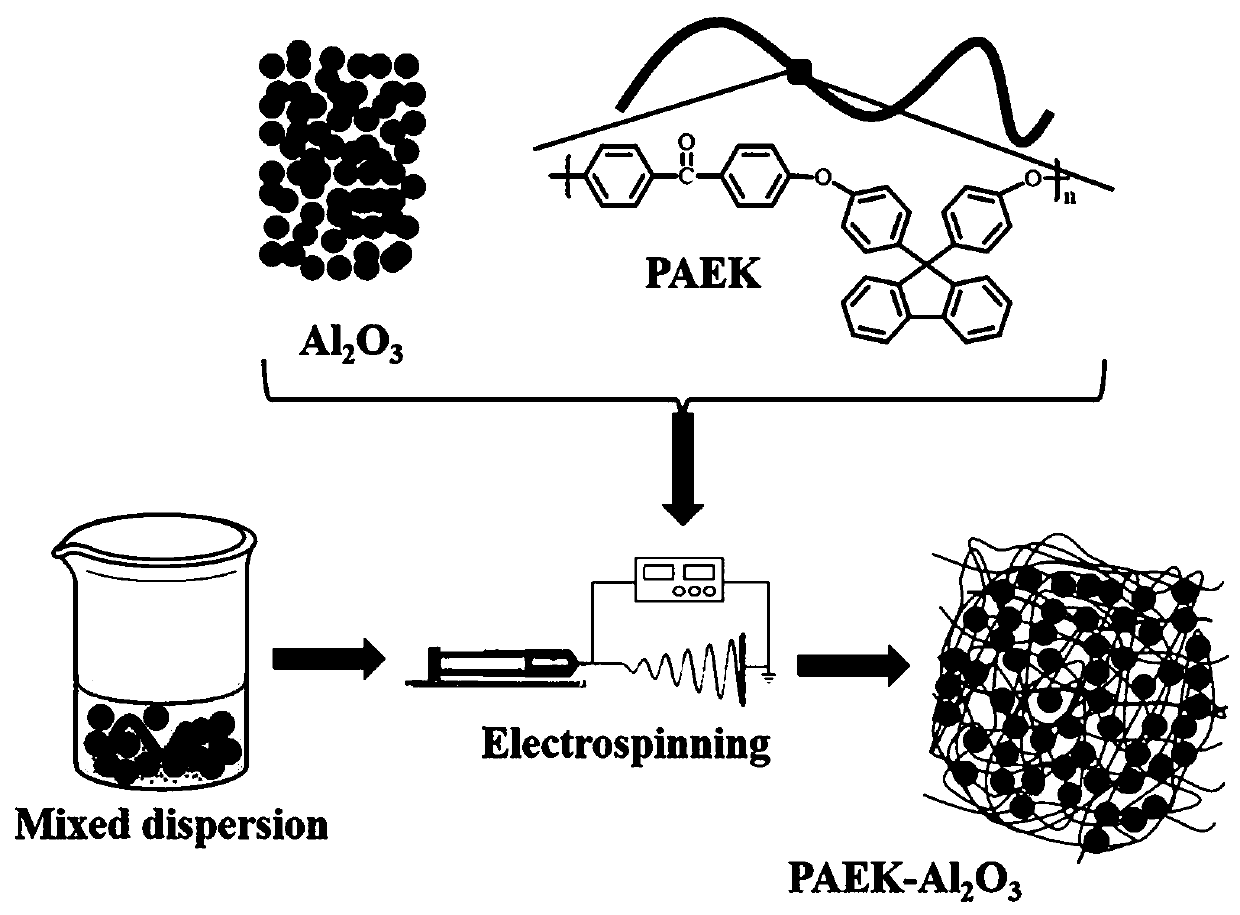

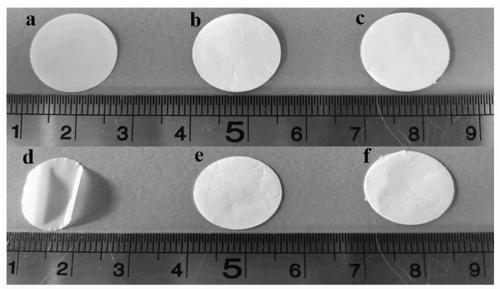

[0059] Apply the above mentioned PAEK membrane and PAEK-Al 2 o 3 The detailed preparation method of the composite film to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com