A kind of copolymerized nanocomposite material and its preparation method and application

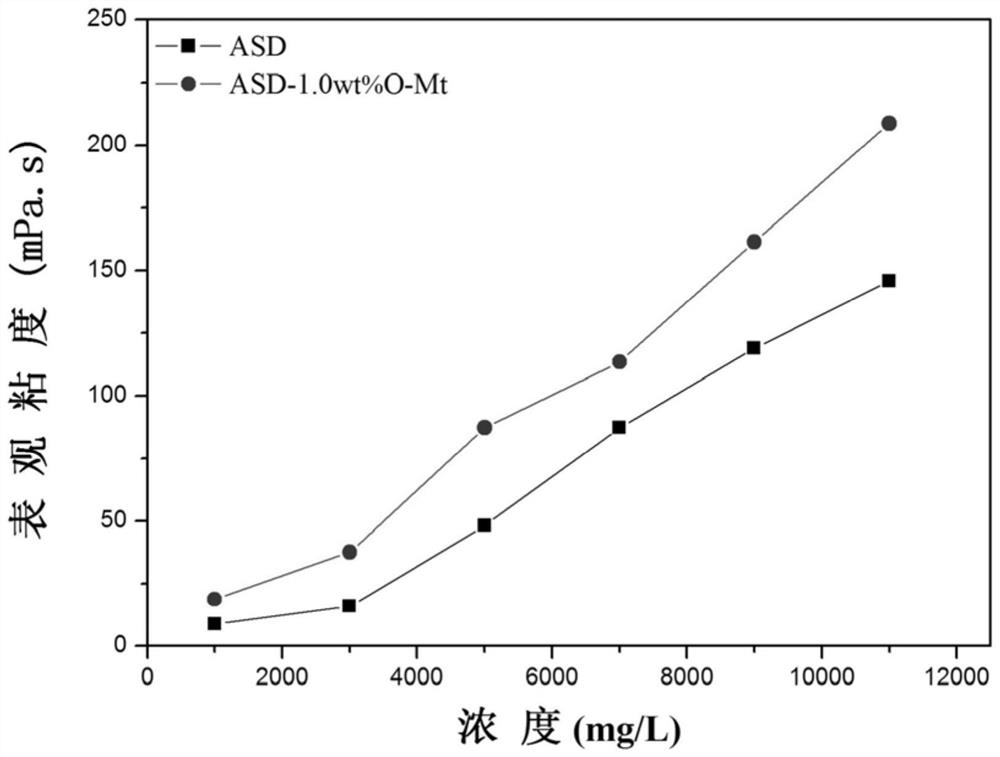

A nano-composite material and copolymerization technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of long-term oil and gas engineering drilling and completion, and achieve good water solubility and viscosity increasing effect, high molecular weight, The effect of nano-dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

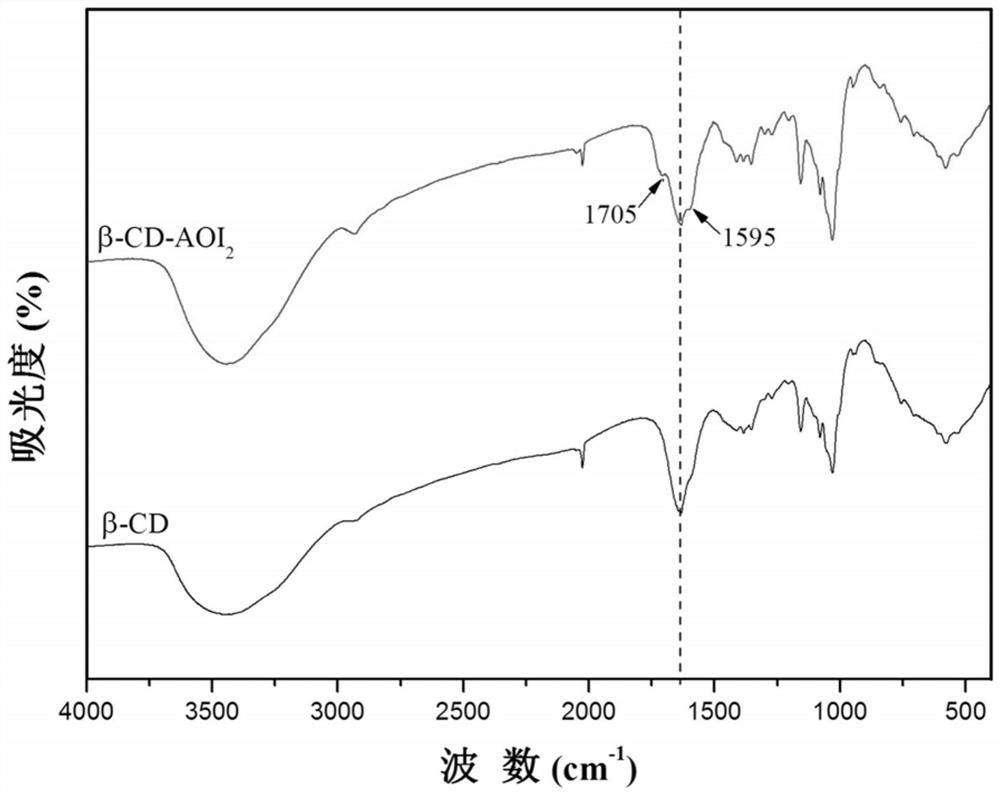

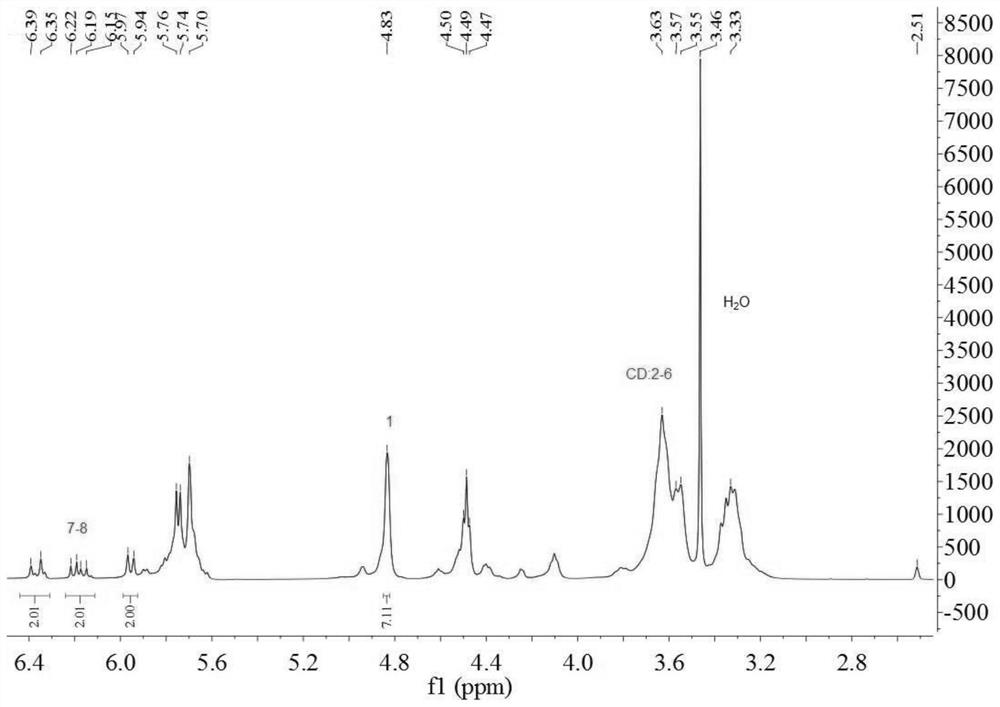

[0069] The present embodiment provides a kind of preparation method of crosslinking agent, comprises the steps:

[0070] i) Put 10 g (7.6 mmol) of industrial-grade β-cyclodextrin powder purified by three recrystallizations and vacuum-dried at 45°C for 48 hours in a 100 mL three-necked flask, and then add 50 mL of N,N- Dimethylacetamide (DMAC) purified liquid, stirred at room temperature under nitrogen protection until the solid was completely dissolved to form a mixed solution A;

[0071] ii) Add 2.14g (i.e. 15.2mmol) of 2-isocyanoethyl acrylate (AOI 2 ), stirring constantly under nitrogen atmosphere for 30min to obtain mixed solution B;

[0072] iii) Under the protection of nitrogen, add 80 μL of stannous isooctanoate purified liquid with a micro-injector, keep it at room temperature and keep stirring for 1.5 hours, then slowly raise the temperature of the reaction to 50°C, and keep this temperature for 8 hours to form a reaction liquid;

[0073] iv) Use a rotary evaporato...

Embodiment 2

[0076] The present embodiment provides a kind of preparation method of cationic surfactant butyl methacrylate cetyl ammonium bromide (DMB), comprises the steps:

[0077] a) 10.38g (ie 66mmol) of 2-(dimethylamino)ethyl methacrylate was dissolved in 100mL of absolute ethanol, and stirred continuously for 15min at a temperature of 50°C to form a reaction system;

[0078] b) Add 20.15 g (i.e. 66 mmol) of hexadecane bromide dropwise to the reaction system prepared in step a) using a constant pressure dropping funnel to form a mixed reaction system, and stir for 24 hours at a temperature of 50° C. to obtain a reaction solution ;

[0079] c) Using a rotary evaporator to concentrate the reaction solution obtained in step b) under reduced pressure, and then undergo acetone recrystallization, suction filtration, washing, and vacuum drying to obtain a snow-white powdery solid product, which is DMB.

Embodiment 3

[0081] This embodiment provides a method for preparing an inorganic nanophase, comprising the steps of:

[0082] Add 3.33g of industrial-grade montmorillonite into a 250mL three-necked flask filled with 100mL of deionized water and ultrasonically disperse it for 30 minutes, then fully stir at room temperature to disperse evenly to form a montmorillonite suspension;

[0083] 3.33 g of DMB prepared in Example 2 dissolved in 50 mL of deionized water was added dropwise to the montmorillonite suspension with a constant pressure dropping funnel, mixed evenly and heated to 50° C. and continued to stir for 24 hours to perform intercalation reaction Form an intercalation reaction system;

[0084] The intercalation reaction system was suction-filtered, washed alternately with ethanol and water three times, then dried in a vacuum oven at 50°C for 24 hours, and then pulverized, ground, and sieved to obtain an inorganic nanophase powder product, which was analyzed by X-ray (λ =0.1540nm) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com