Cuprous oxide doped lithium ion battery negative electrode material, preparation method thereof, application, and lithium ion battery

A technology for lithium cuprous oxide and lithium-ion batteries, which is applied in battery electrodes, copper oxide/copper hydroxide, secondary batteries, etc., and can solve the problem of short cycle life, low capacity, and impact on the cycle discharge capacity and cycle use of lithium-ion batteries Life and other issues, to achieve high production efficiency, simple equipment, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

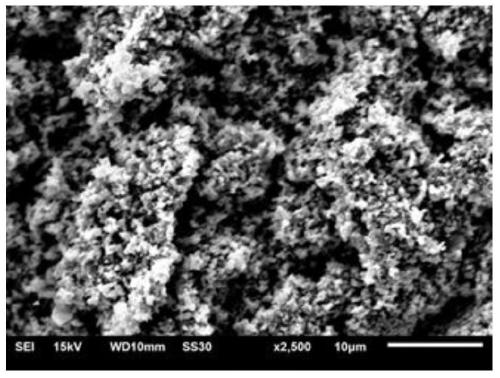

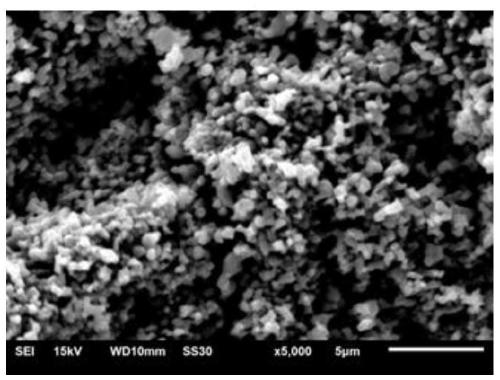

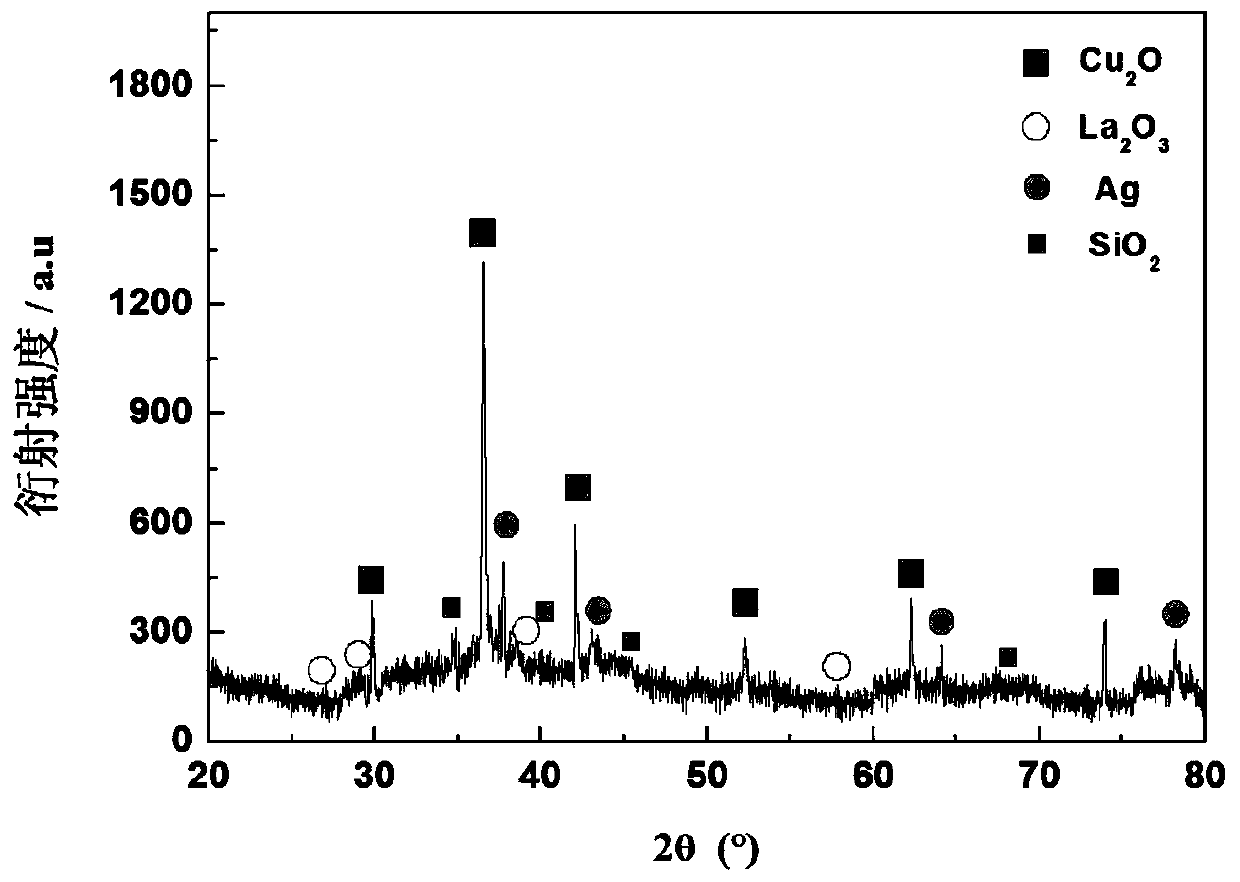

[0073] A kind of doping coating doped Cu 2 The preparation method of O negative electrode material, its step is:

[0074] The first step, to 50mLCu 2+ The concentration is 0.1M, Cu 2+ :La 3+ Add 5mL, 0.1M potassium hydroxide solution to the mixture solution of copper nitric acid and lanthanum nitrate with a molar ratio of 100:0.2, and 5 mmol (about 0.34 g) of ethylenediamine, and stir to mix evenly;

[0075] In the second step, 10 mL of water chestnut starch reducing agent solution with a concentration of 5 wt % and 5 mL of acetic acid solution with a concentration of 0.1 M were added to the mixed solution, and stirred and reacted for 45 minutes at 45° C. to obtain a mixed solution;

[0076]In the third step, add 0.5 g of sodium silicate powder to the mixture solution obtained in the second step, stir for 3 minutes, add 10 mL of hydrochloric acid with a concentration of 0.2 M, and continue stirring for 25 minutes; stand still for 5 minutes, and centrifuge the mixture to rem...

Embodiment 2

[0080] A kind of doping coating doped Cu 2 The preparation method of O negative electrode material, its step is:

[0081] The first step, to 100mLCu 2+ The concentration is 0.3M, Cu 2+ :La 3+ Add 10mL, 0.2M sodium hydroxide solution to the mixture solution of copper sulfate, lanthanum sulfate, and 30 mmoles of propylenediamine in a molar ratio of 100:0.4, and stir and mix evenly;

[0082] In the second step, add 10 mL of lotus root starch reducing agent solution with a concentration of 8 wt % to the above mixed solution, add 10 mL of 1.0 M propionic acid solution, and stir for 35 minutes at 55 ° C;

[0083] In the third step, add 1.5 g of sodium silicate powder to the mixture solution obtained in the second step, stir for 6 minutes, add 15 mL of 0.4 M hydrochloric acid, and continue stirring for 35 minutes; stand still for 10 minutes, and centrifuge the mixture to remove the solution. The precipitate was rinsed with 0.01M sodium hydroxide solution for 3 to 5 times to obtai...

Embodiment 3

[0087] A kind of doping coating doped Cu 2 The preparation method of O negative electrode material, its step is:

[0088] The first step, to 200mLCu 2+ The concentration is 0.75M, Cu 2+ :La 3+ Molar ratio is 100:0.6 cupric chloride and lanthanum chloride, in the complex mixture solution containing 0.15 mole butammonium diammonium, add the lithium hydroxide solution that 20mL concentration is 0.3M, stir and mix;

[0089] In the second step, add 40 mL of sweet potato starch solution with a concentration of 12 wt % to the above mixed solution, add 20 mL of butyric acid solution with a concentration of 0.3 M, and stir for 25 minutes at 65 ° C;

[0090] In the third step, add 4.0 g of sodium silicate powder to the mixture solution obtained in the second step, stir for 12 minutes, add 30 mL of hydrochloric acid with a concentration of 0.8 M, and continue stirring for 45 minutes; stand still for 20 minutes, and centrifuge the mixture to remove solution, and the precipitate was ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com