A kind of separation and extraction method of N-acetylneuraminic acid

A technology for the extraction of acetylneuraminic acid, which is applied in the field of separation and extraction of N-acetylneuraminic acid, can solve the problems of difficult solid-liquid separation, low overall yield, and high separation cost, so as to save acid and alkali consumption and operation The effect of time and process is simple and easy to operate, and the separation cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

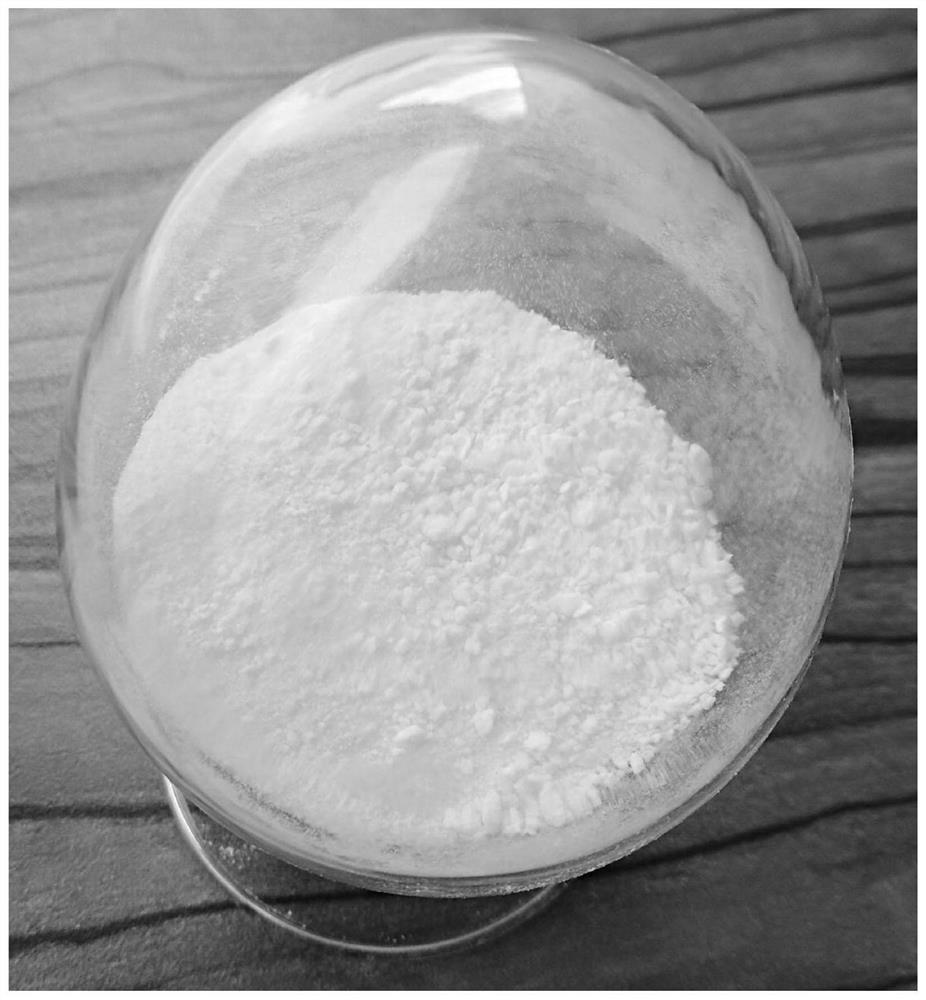

Image

Examples

Embodiment 1

[0042]1) 2000mL of fermentation broth containing polysialic acid (polyacid hydrolysis solution (8.1g / L)) Use phosphoric acid to adjust the pH to 1.5 and carry out acid hydrolysis at 65°C for 3 hours to obtain 2050mL of acid hydrolysis solution; the saliva in the acid hydrolysis solution The concentration of acid is 7.9g / L; except for sialic acid, the main components of the acid solution are sugar, nucleic acid, salt, pigment, amino acid, protein, organic acid and so on.

[0043] Wherein, the fermented liquid containing sialic acid is that Escherichia coli transforms glucose, corn steep liquor, vitamins, inorganic salts, yeast extract, etc. to form polysialic acid.

[0044] 2) Pass the acid solution in step 1) through a 50nm ceramic membrane, collect the permeate, and wash the retentate with tap water until the retentate does not contain sialic acid, and collect the permeate through the ceramic membrane.

[0045] 3) Pass the ceramic membrane permeate in step 2) through a 2000 D...

Embodiment 2

[0095] 1) Adjust 2000 mL of fermentation broth containing polysialic acid (8.1 g / L polysialic acid hydrolyzate) to pH 2.5 with phosphoric acid and carry out acid hydrolysis at 80°C for 5 hours to obtain 2040 mL of acid hydrolyzate; the saliva in the acid hydrolyze The acid concentration was 7.94g / L.

[0096] 2) Pass the acid solution in step 1) through a 50nm ceramic membrane, collect the permeate, and wash the retentate with tap water until the retentate does not contain sialic acid, and collect the permeate through the ceramic membrane.

[0097] 3) The ceramic membrane permeate in step 2) is passed through a 5000Da membrane to remove macromolecular impurities such as protein and nucleic acid, and the retentate is continuously washed until it does not contain sialic acid, and the ultrafiltration membrane permeate is collected.

[0098] 4) The ultrafiltration membrane permeate in step 3) is concentrated and desalinated by a 100Da membrane, and continuously washed with deionize...

Embodiment 3

[0105] 1) Adjust 2000mL of fermentation broth containing polysialic acid (8.1g / L polysialic acid hydrolyzate) to pH 2.0 with phosphoric acid and carry out acid hydrolysis at 85°C for 3.5h to obtain 2049mL of acid hydrolyzate; The concentration of sialic acid was 7.9g / L.

[0106] 2) Pass the acid solution in step 1) through a 50nm ceramic membrane, collect the permeate, and wash the retentate with tap water until the retentate does not contain sialic acid, and collect the permeate through the ceramic membrane.

[0107] 3) Pass the ceramic membrane permeate in step 2) through a 4000Da membrane to remove macromolecular impurities such as protein and nucleic acid, and continuously wash the retentate until it does not contain sialic acid, then collect the ultrafiltration membrane permeate.

[0108] 4) The ultrafiltration membrane permeate in step 3) is concentrated and desalinated by a 200Da membrane, and continuously washed with deionized water until the conductivity of the permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com