Heat-conducting silica gel sheet for heat dissipation of lithium battery of new energy automobile and preparation method thereof

A technology for new energy vehicles and heat-conducting silicone sheets, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as easy formation of high temperature environment, failure of power system control of new energy vehicles, impact on battery performance and state of charge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

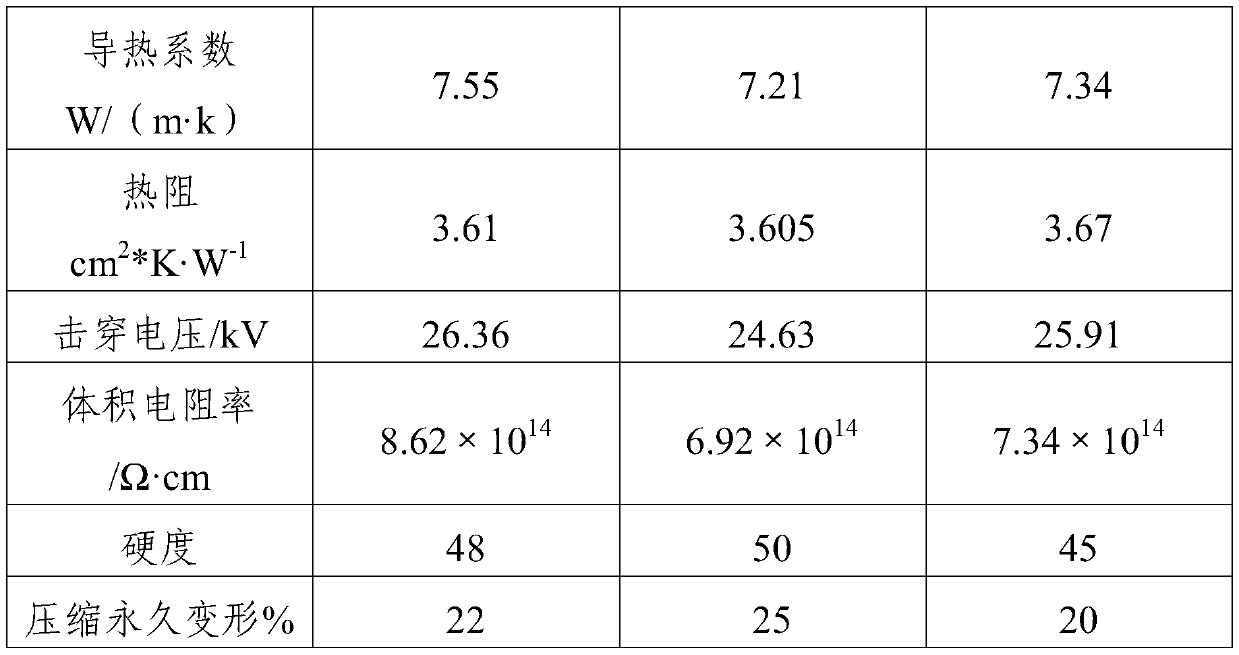

Embodiment 1

[0037] A thermally conductive silica gel sheet for heat dissipation of lithium batteries of new energy vehicles, prepared from the following raw materials in parts by weight:

[0038]30 parts of vinyl-terminated methyl silicone oil, 2 parts of α, ω-terminated hydroxyl polydimethylsiloxane, 5 parts of polymethylhydrogen siloxane, 0.5 parts of tetramethoxysilane, graphene-doped boron nitride 30 parts, 15 parts of fumed white carbon black, 2 parts of microcrystalline paraffin, 0.1 part of dibutyltin dilaurate, 6 parts of KH-5706, 20 parts of methyl vinyl MQ silicone resin, 0.2 parts of ethynyl cyclohexanol, allyl 6 parts of glycidyl ether, 1 part of zinc dimethyldithiocarbamate, 0.01 part of hydrosilylation catalyst, and 150 parts of water.

[0039] The preparation method of graphene-doped boron nitride is as follows:

[0040] Borax and urea with a molar mass ratio of 1:2.5 were dried and dehydrated separately, mixed by ball milling, added to the reaction kettle, heated to 300°C...

Embodiment 2

[0044] A thermally conductive silica gel sheet for heat dissipation of lithium batteries of new energy vehicles, prepared from the following raw materials in parts by weight:

[0045] 36 parts of vinyl-terminated methyl silicone oil, 2 parts of α, ω-terminated hydroxyl polydimethylsiloxane, 5 parts of polymethylhydrogen siloxane, 0.2 parts of tetramethoxysilane, graphene-doped boron nitride 30 parts, 15 parts of fumed white carbon black, 2 parts of microcrystalline paraffin, 0.05 parts of dibutyltin dilaurate, 5 parts of KH-570, 25 parts of methyl vinyl MQ silicone resin, 0.2 parts of ethynyl cyclohexanol, 10 parts of propyl glycidyl ether, 1 part of zinc dimethyldithiocarbamate, 0.01 part of hydrosilylation catalyst, and 100 parts of water.

[0046] The preparation method of graphene-doped boron nitride is as follows:

[0047] Borax and urea with a molar mass ratio of 1:2.5 were dried and dehydrated separately, mixed by ball milling, added to the reaction kettle, and heated ...

Embodiment 3

[0051] A thermally conductive silica gel sheet for heat dissipation of lithium batteries of new energy vehicles, prepared from the following raw materials in parts by weight:

[0052] 40 parts of vinyl-terminated methyl silicone oil, 2 parts of α, ω-terminated hydroxyl polydimethylsiloxane, 2 parts of polymethylhydrogen siloxane, 0.2 parts of tetramethoxysilane, graphene-doped boron nitride 20 parts, 20 parts of fumed white carbon black, 2 parts of microcrystalline paraffin, 0.1 parts of dibutyltin dilaurate, 6 parts of KH-570, 25 parts of methyl vinyl MQ silicone resin, 0.3 parts of ethynyl cyclohexanol, olefin 5 parts of propyl glycidyl ether, 1.5 parts of zinc dimethyldithiocarbamate, 0.01 part of hydrosilylation catalyst, and 150 parts of water.

[0053] The preparation method of graphene-doped boron nitride is as follows:

[0054] Borax and urea with a molar mass ratio of 1:2.5 were dried and dehydrated separately, mixed by ball milling, added to the reaction kettle, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com