Pretreatment device and method for kitchen waste leachate

A pretreatment device and a technology of kitchen waste, applied in the direction of filtration treatment, contaminated groundwater/leachate treatment, multi-stage water treatment, etc., can solve problems such as equipment failure, increased salinity, and difficult treatment, and achieve Reduction of secondary investment in equipment, easy secondary acidification, and easy safety and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

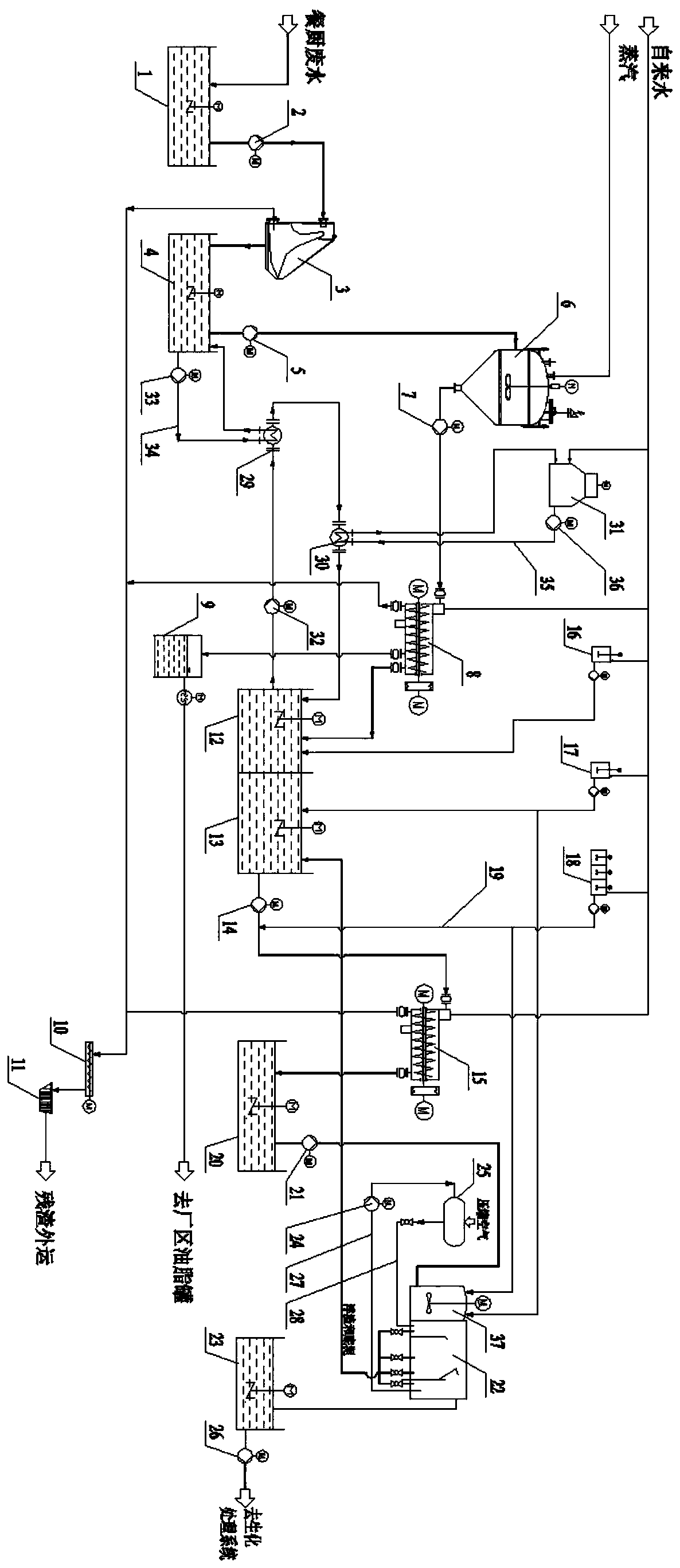

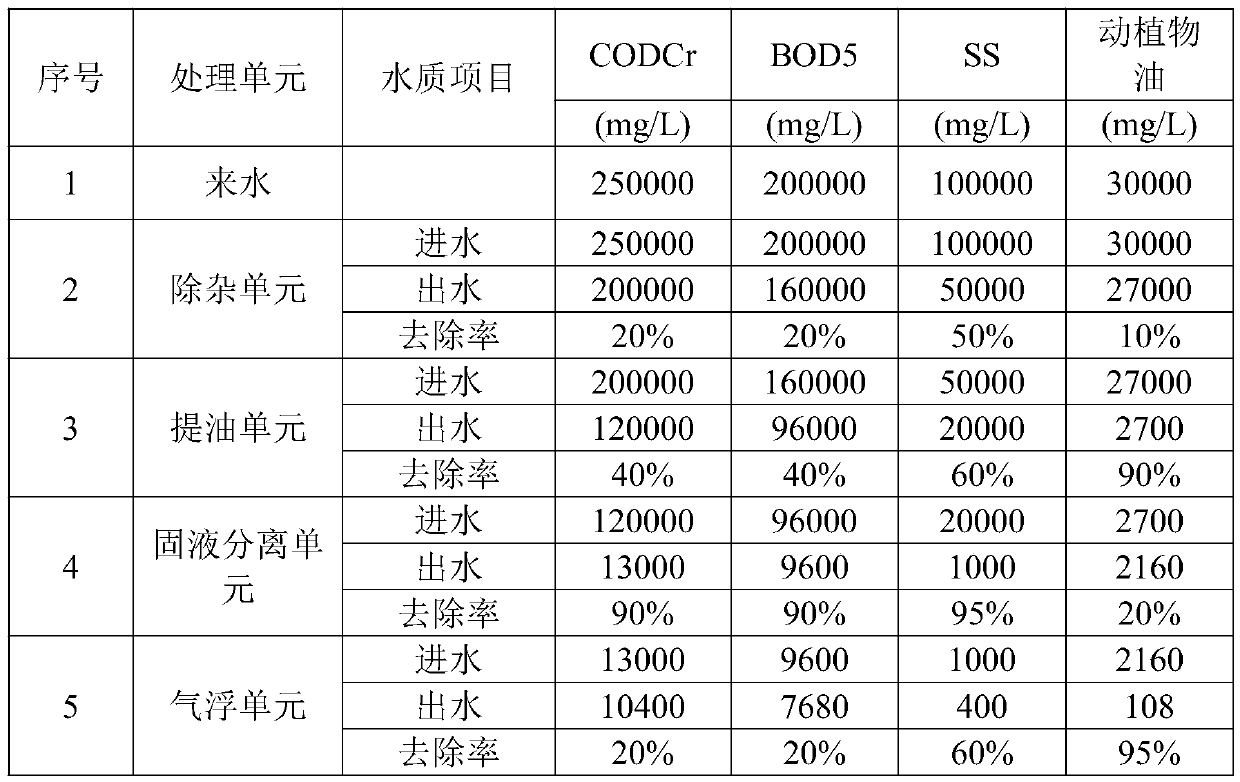

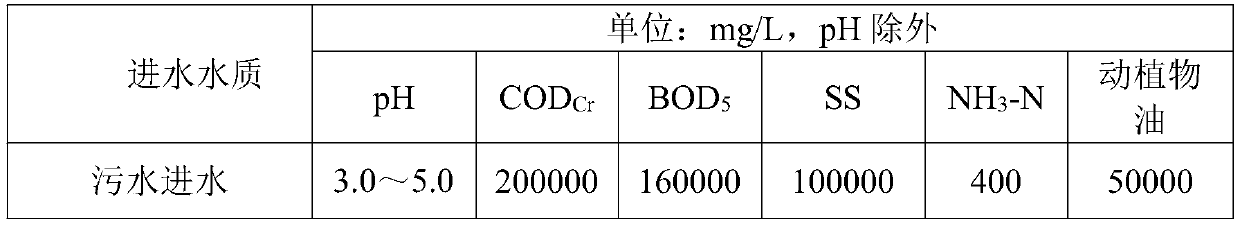

[0032] Such as figure 1 As shown, a pretreatment device for food waste leachate includes an impurity removal unit, an oil extraction unit, a solid residue separation unit, an air flotation unit, and a temperature adjustment and heat recovery unit.

[0033] The impurity removal unit includes a wastewater collection tank 1, a wastewater delivery pump-2, a hydraulic screen 3 and a buffer tank-4, one end of the kitchen wastewater delivery pipeline is connected to the inlet of the wastewater collection tank 1, and the outlet of the wastewater collection tank 1 passes through the pipeline It is connected with waste water delivery pump one 2, hydraulic screen 3 and buffer pool one 4 in turn. Since the kitchen waste water contains more viscous particles and grease, it has a high viscosity, and it is easy to block when using ordinary sewage grilles. It is easy to increase the SS in the waste water by using a mechanical extrusion impurity remover, so the hydraulic sieve 2 in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com