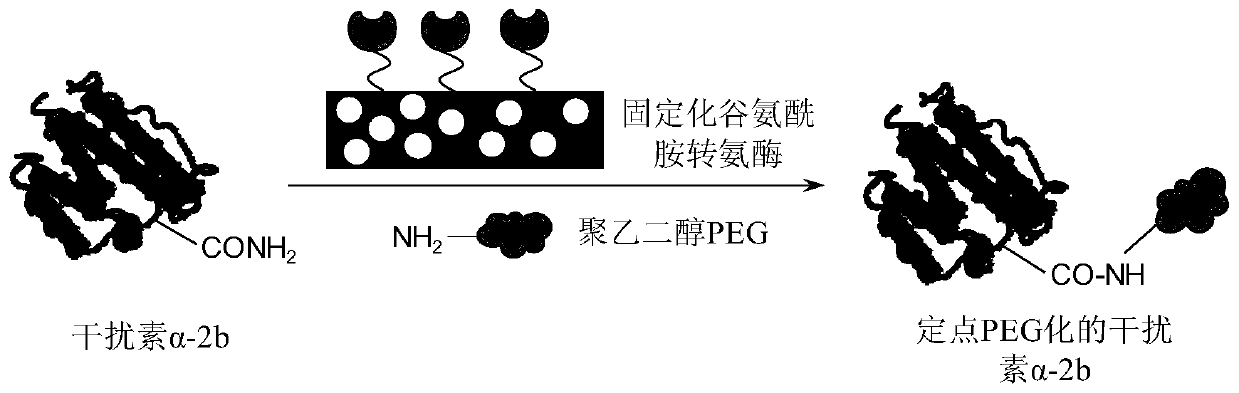

Method for carrying out fixed-point polyethylene glycol long-acting modification on interferon IFN alpha-2b

A technology of polyethylene glycol and interferon, applied in the direction of interferon, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of difficult separation, decreased activity, difficult quality control, etc., and achieve easy separation and recovery, production Effects of cost reduction and high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

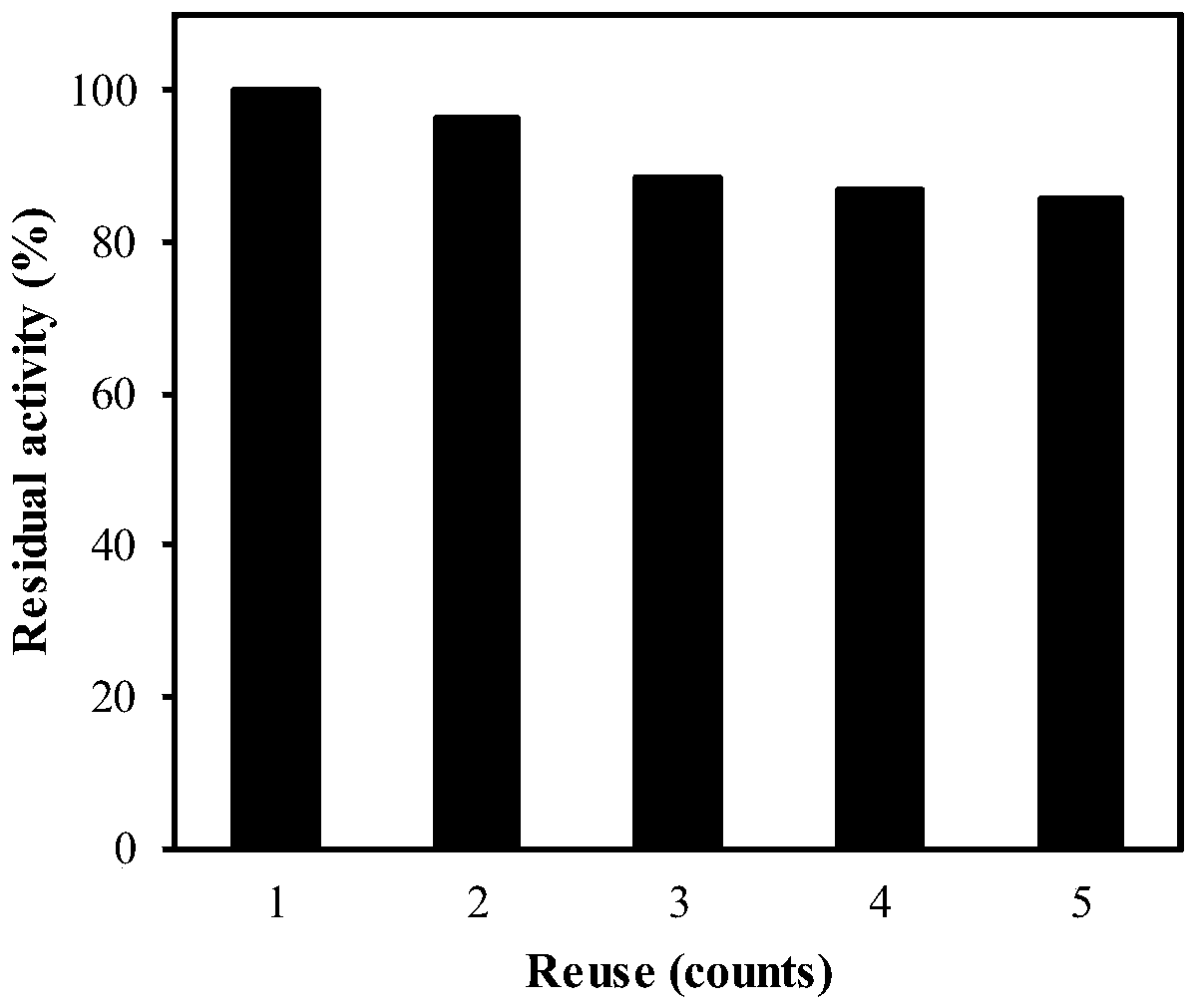

Embodiment 1

[0024] Use the porous film with carboxyl groups to immobilize transglutaminase, the steps are as follows: the carboxylated porous film is placed in 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC ) and N-hydroxysulfosuccinimide (Sulfo-NHS) in 2-(N-morpholine)ethanesulfonic acid (MES) buffer solution (pH 4.5, 0.1 M), in which the concentration of EDC and Sulfo-NHS Both were 10 mg / mL to activate the carboxyl groups on the porous membrane at 4 °C. After activating for 1.5 h, the film was washed with double distilled water, and then the activated porous film was placed in a phosphate buffer solution of transglutaminase to react for 12 h, and then fully washed with double distilled water, and the immobilized film was obtained. Porous film with transglutaminase.

[0025] Interferon IFN α-2b was dissolved in phosphate buffer (pH 7.4, 10 mM) to form a protein solution with a concentration of 1.5 mg / mL, and 1 times the amount of interferon IFN α-2b was added to the so...

Embodiment 2

[0028] Use porous microspheres with epoxy groups to immobilize transglutaminase, the steps are as follows: equilibrate the porous microspheres with epoxy groups in phosphate buffer (pH 8.0, 50 mM) for 2 h, centrifuge Afterwards, it was transferred to the phosphate buffer solution in which transglutaminase was dissolved for enzyme immobilization, and the whole reaction system was stirred and reacted at room temperature for 18 h to complete the enzyme immobilization. The porous microspheres were subjected to multiple centrifugation washes to remove physically adsorbed transglutaminase and by-products.

[0029] Interferon IFN α-2b was dissolved in phosphate buffer (pH 7.4, 10 mM) to form a protein solution with a concentration of 1.5 mg / mL, and 1.01 times the amount of interferon IFN α-2b was added to the solution with Polyethylene glycol (molecular weight 5kDa, branched) with primary amino groups was stirred to dissolve completely, and then immobilized transglutaminase was added...

Embodiment 3

[0032] Use porous fibers with aldehyde groups to immobilize transglutaminase, and the steps are as follows: the porous fibers with aldehyde groups are placed in phosphate buffer (pH 8.0, 50 mM) for 2 h, centrifuged to remove the supernatant and transferred The enzyme was immobilized in the phosphate buffer solution dissolved with transglutaminase, and the whole reaction system was stirred at room temperature for 18 h to complete the enzyme immobilization. Multiple centrifuge washes were performed to remove physically adsorbed transglutaminase and by-products.

[0033] Interferon IFN α-2b was dissolved in phosphate buffer (pH 7.4, 10 mM) to form a protein solution with a concentration of 1.5 mg / mL, and 1.03 times the amount of interferon IFN α-2b was added to the solution with Polyethylene glycol with primary amino groups (molecular weight 10kDa, multi-arm type) was stirred to dissolve completely, and then immobilized transglutaminase was added. The whole reaction system was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com