Environment-friendly water-based adhesive and preparation method thereof

A water-based adhesive, environmentally friendly technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of easy deterioration, poor dispersion stability, etc., to achieve sufficient initial adhesion, excellent weather resistance, storage and transportation. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

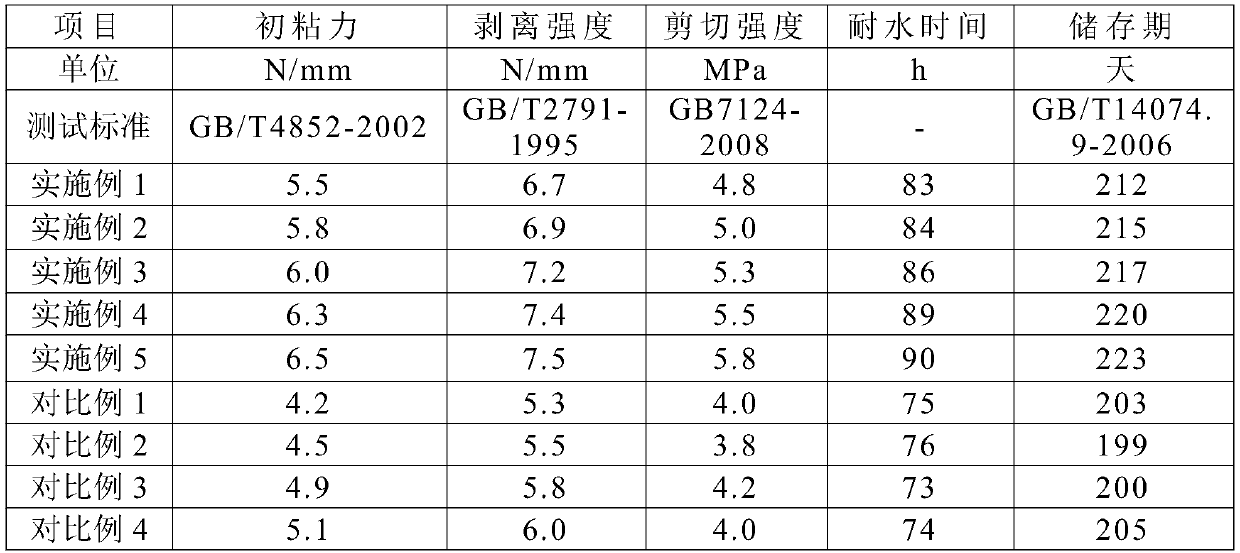

Examples

Embodiment 1

[0032] An environmentally friendly water-based adhesive is characterized in that it comprises the following raw materials in parts by weight: 30 parts of acrylic acid modified amino-terminated water-soluble hyperbranched polyamide, (chloromethyl) boric acid pinacol ester ionized modified N ,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic rosin 10 parts, triethoxysilylpropyl maleic acid 3 parts, 5 parts of polyethylene glycol diacrylate, 4-8 parts of attapulgite, 1 part of fullerene-based carbon quantum dots, 0.5 parts of sodium dodecylbenzenesulfonate, 25 parts of deionized water, 3 parts of ethanol, benzoin 1 part of ether, 0.5 parts of silane coupling agent KH5500.

[0033] The (chloromethyl)boronic acid pinacol ester ionized modified N,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic acid The preparation method of rosin, comprises the steps:

[0034] Step S1. Add bis(trimethoxysilylpropyl...

Embodiment 2

[0039] An environmentally friendly water-based adhesive is characterized in that it comprises the following raw materials in parts by weight: 33 parts of acrylic acid modified amino-terminated water-soluble hyperbranched polyamide, (chloromethyl) boric acid pinacol ester ionized modified N ,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic rosin 11 parts, triethoxysilylpropyl maleic acid 4 parts, 6 parts of polyethylene glycol diacrylate, 5 parts of attapulgite, 1.5 parts of fullerene-based carbon quantum dots, 0.7 parts of polyoxypropylene polyoxyethylene glyceryl ether, 27 parts of deionized water, 4 parts of tetrahydrofuran, benzoin isopropyl 1.5 parts of ether, 0.6 parts of silane coupling agent KH5600.

[0040] The (chloromethyl)boronic acid pinacol ester ionized modified N,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic acid The preparation method of rosin, comprises the steps:

[0041]...

Embodiment 3

[0046] An environmentally friendly water-based adhesive is characterized in that it includes the following raw materials in parts by weight: 35 parts of acrylic acid modified amino-terminated water-soluble hyperbranched polyamide, (chloromethyl) boric acid pinacol ester ionized modified N , N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic rosin 13 parts, triethoxysilylpropyl maleic acid 4.5 parts, 7 parts of polyethylene glycol diacrylate, 6 parts of attapulgite, 2 parts of fullerene-based carbon quantum dots, 1 part of nonylphenol polyoxyethylene ether, 30 parts of deionized water, 4.5 parts of dioxane, α , 2 parts of α-diethoxyacetophenone, 0.8 parts of silane coupling agent KH5700.

[0047] The (chloromethyl)boronic acid pinacol ester ionized modified N,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic acid The preparation method of rosin, comprises the steps:

[0048] Step S1. Add bis(trim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com