Light response liquid crystal elastomer fiber membrane and preparation method thereof

A technology of liquid crystal elastomer and photoresponse, which is applied in fiber processing, liquid crystal materials, chemical instruments and methods, etc. It can solve problems such as difficulty in orientation of liquid crystal polymers, long time, and difficulty in preparing multi-layer films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

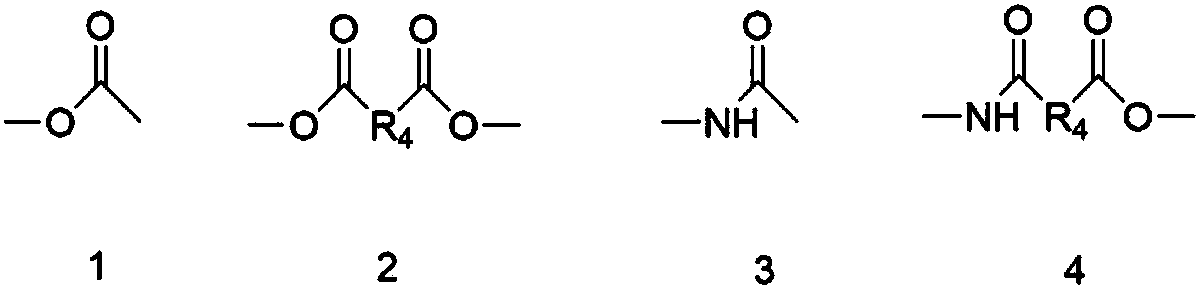

[0047] Polymerization and purification were carried out according to the free radical polymerization method commonly used in the literature. The structural formula and monomer structure of the synthesized polymer are shown below, named P6AZCN 1 -co-M4OH 1 .

[0048]

[0049] Put 2 g of the prepared copolymer in a 25 ml single-necked flask, add 8 g of N,N'-dimethylformamide at 60°C, and stir for 12 hours to prepare a spinning solution. The concentration of the spinning solution was 20 wt%, and the spinning solution was transferred to a 10 mL syringe, and defoamed overnight at 4°C.

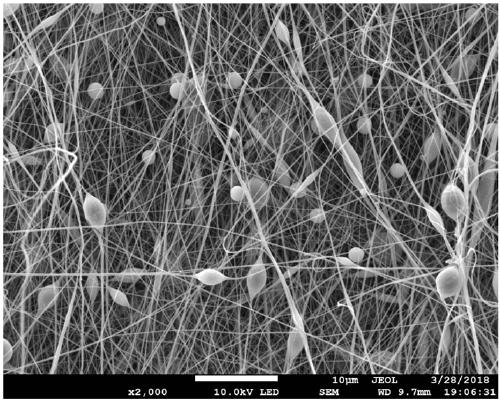

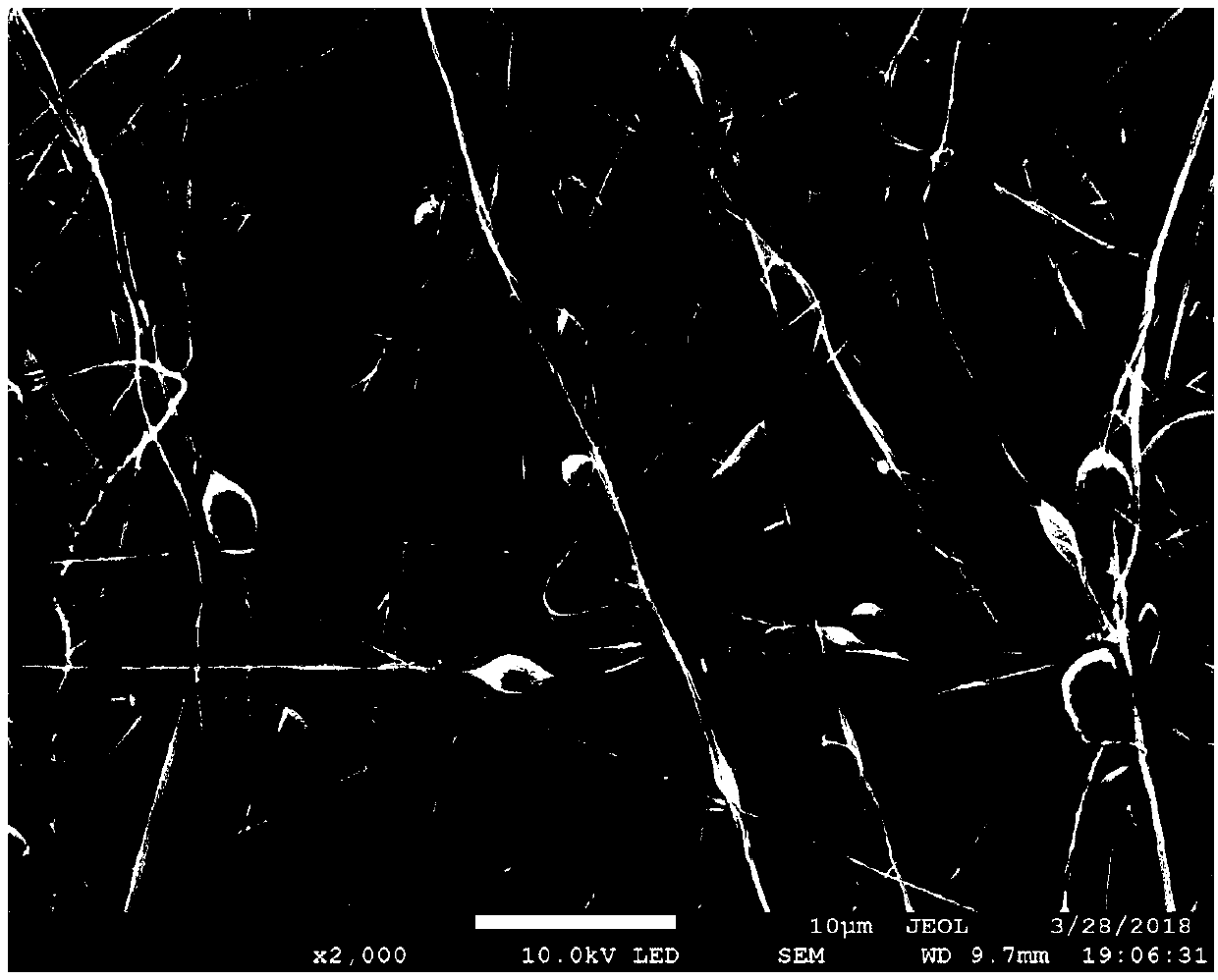

[0050] Spinning is carried out by using an electrostatic spinning machine with a receiving roller, and the temperature inside the spinning machine is controlled below 20° C., and the humidity is below 20% rh. The propulsion speed is 0.004ml / min, the receiving distance is 10cm, the voltage is 10kV, and the rotating speed of the receiving roll is 500r / min fixed axis spinning for 4h to obtain a f...

Embodiment 2

[0052] Polymer using P6AZ 2 -co-M4OH 1 , the molecular formula and monomer structure are shown in the figure, m:n=2:1.

[0053]

[0054]Mix with dimethylformamide solution of 8wt% polyamic acid to prepare a solution containing 5wt% photoresponsive liquid crystal polymer (the mass ratio of non-azo polymer to azo liquid crystal polymer is 95:5), spin The concentration of silk liquid is 30wt%. Transfer the solution to a 10 mL syringe and defoam overnight at 4 °C.

[0055] Spinning is carried out by using an electrostatic spinning machine with a receiving roller, and the temperature inside the spinning machine is controlled below 20° C., and the humidity is below 20% rh. The propulsion speed is 0.004ml / min, the receiving distance is 10cm, the voltage is 10kV, and the receiving roll speed is 1000r / min fixed axis spinning for 4h to obtain a fiber film with a thickness of 20μm. The cross-linked fiber membrane was obtained by immersing in medium overnight, and the properties ar...

Embodiment 3

[0057] Polymer using P6AZC4 2 -co-M4OH 1 , the molecular formula is as follows.

[0058]

[0059] Mix with 10wt% polyurethane elastomer solution [solvent is dimethylformamide] to prepare a solution containing 10wt% photoresponsive liquid crystal polymer composite material, the mass ratio of non-azo polymer to azo liquid crystal polymer is 90:10 . The concentration of the spinning solution was 30 wt%, and the solution was transferred to a 10 mL syringe and defoamed overnight at 4°C.

[0060] Spinning is carried out by using an electrostatic spinning machine with a receiving roller, and the temperature inside the spinning machine is controlled below 20° C., and the humidity is below 20% rh. The propulsion speed is 0.004ml / min, the receiving distance is 10cm, the voltage is 10kV, and the receiving roll speed is 1000r / min fixed axis spinning for 4h to obtain a fiber film with a thickness of 20μm. The cross-linked fiber membrane was obtained by immersing in medium overnight,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com