A kind of fluorine-containing oil-resistant anti-swelling silicone rubber foam material and preparation method thereof

A foam material and anti-swelling technology, which is applied in the field of silicone rubber foam materials, can solve the problems of increased steric resistance of silicone rubber chain segments, poor dispersion compatibility of foaming agents, and difficulties in vulcanization and cross-linking foaming reactions. The effect of increased compatibility of the two-phase interface, simple and efficient preparation process, and excellent anti-swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

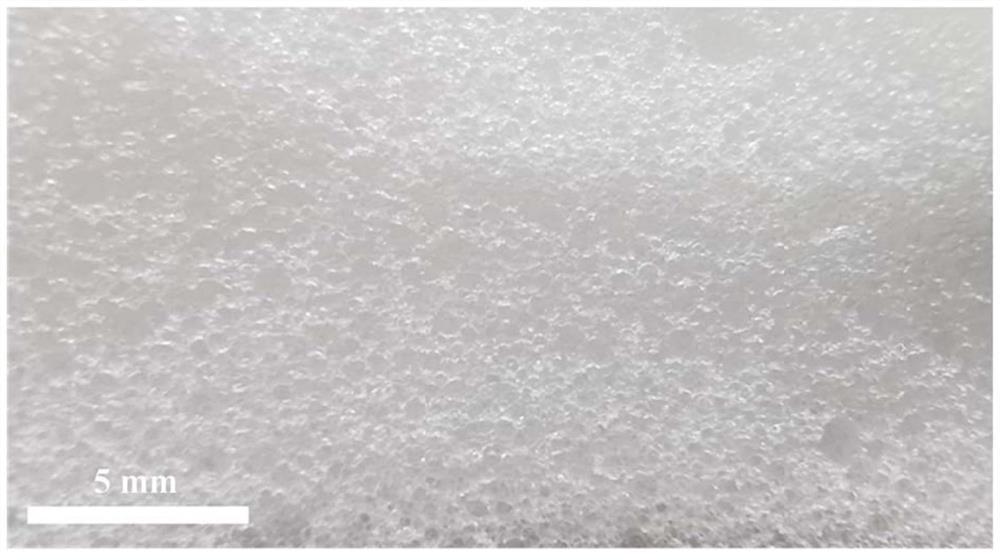

[0038] Preparation of fluorine-containing oil-resistant and swelling-resistant silicone rubber foam (FSiRF):

[0039] Take 4.0 g of hydrogen-containing fluorosilicone oil with a viscosity of 55 mPa s and a hydrogen content of 0.3 wt%, and 16.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.15 wt%, and add 0.1 g [(1,1- Dimethyl-2-propynyl)oxyl]trimethylsilane and 0.4g fluorosilicone surfactant AC-805 (Ark) mixed ethylene glycol (mass ratio 1:1), fully mixed evenly by mechanical stirring Then prepare component A; meanwhile, take 20.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.15 wt %, add 0.47 g of chloroplatinic acid catalyst with a Pt mass concentration of 3000 ppm, and mix well by mechanical stirring Then prepare component B. Then, components A and B were mixed by mechanical stirring for 30s at a mass ratio of 1:1. After mixing evenly, let it react at room temperature for 5 minutes, and then put it in an o...

Embodiment 2

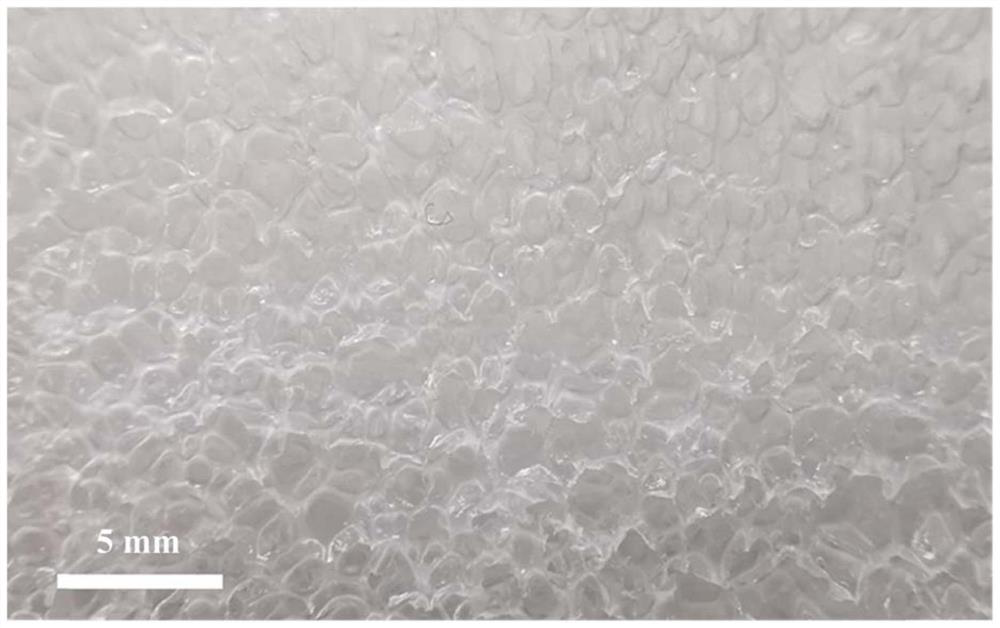

[0041] Preparation of fluorine-containing oil-resistant and anti-swelling silicone rubber foam material:

[0042] Take 5.0 g of hydrogen-containing fluorosilicone oil with a viscosity of 55 mPa·s and a hydrogen content of 0.3 wt%, and 15.0 g of a perfluorosilicone oil with a viscosity of 20 Pa·s and a vinyl content of 0.15 wt%, and add 0.1 g of 1-acetylene-1- (Trimethylsilyloxy)cyclohexane and 0.4g of glycerol (mass ratio 1:1) mixed with fluorosilicone surfactant BNK-4036 (Changhui Chemical Industry) were prepared by mechanical stirring and thorough mixing. Component A; at the same time, take 20.0g of perfluorosilicone oil with a viscosity of 20Pa·s and a vinyl content of 0.15wt%, add 0.47g of a chloroplatinic acid catalyst with a Pt mass concentration of 3000ppm, and prepare it after fully mixing it uniformly by mechanical stirring Component B. Then, components A and B were mixed by mechanical stirring for 30s at a mass ratio of 1:1. After mixing evenly, let it react at room...

Embodiment 3

[0044] Preparation of fluorine-containing oil-resistant and anti-swelling silicone rubber foam material:

[0045] Take 6.0 g of hydrogen-containing fluorosilicone oil with a viscosity of 75 mPa·s and a hydrogen content of 0.3 wt%, and 14.0 g of a perfluorosilicone oil with a viscosity of 20 Pa·s and a vinyl content of 0.35 wt%, and add 0.1 g [(1,1- Dimethyl-2-propynyl) oxygen group] triethylsilane and 0.4g glycerol (mass ratio 1:1) mixed with fluorosilicone surfactant BNK-4036 (Changhui Chemical Industry), by mechanical stirring Mix well and prepare component A; at the same time, take 20.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.35 wt %, add 0.67 g of chloroplatinic acid catalyst with a Pt mass concentration of 3000 ppm, and stir it mechanically After mixing well and uniformly, component B is prepared. Then, components A and B were mixed by mechanical stirring for 30 seconds at a mass ratio of 1:1, and allowed to react at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com