Camellia oleifera shell carbon powder material and application thereof in purifying antibiotic wastewater

A technology of camellia oleifera shell and carbon powder, which is applied in other chemical processes, carbon preparation/purification, water/sewage treatment, etc., can solve problems affecting the health and stability of the ecological environment, increase the adsorption capacity, and complicate the preparation process, and achieve adsorption balance The effect of short time, easy recovery and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A camellia oleifera shell carbon powder material in this example, the specific preparation steps are as follows:

[0031] (1) Mechanically grinding camellia oleifera shells into powder;

[0032] (2) Calculated according to the mass ratio, the ratio of camellia oleifera shell powder: water is 1:30, weigh 2 g of camellia oleifera shell powder and 60ml of water, pour them into a beaker, and place the beaker in an ultrasonic cleaner to ultrasonicate the experimental drug After dispersing for 1 hour, stir for 6 hours, put the mixed solution in a hydrothermal reaction kettle, bake in an oven at 230°C for 12 hours, filter and wash, and dry in an oven at 60°C for 24 hours to obtain carbon powder;

[0033] (3) Calculated according to the mass ratio, the obtained carbon powder: KOH ratio is 1:4. After grinding evenly, put it in a porcelain boat and put it in a tube furnace. Under the protection of argon, it takes 125 minutes from room temperature to roasting The temper...

Embodiment 2

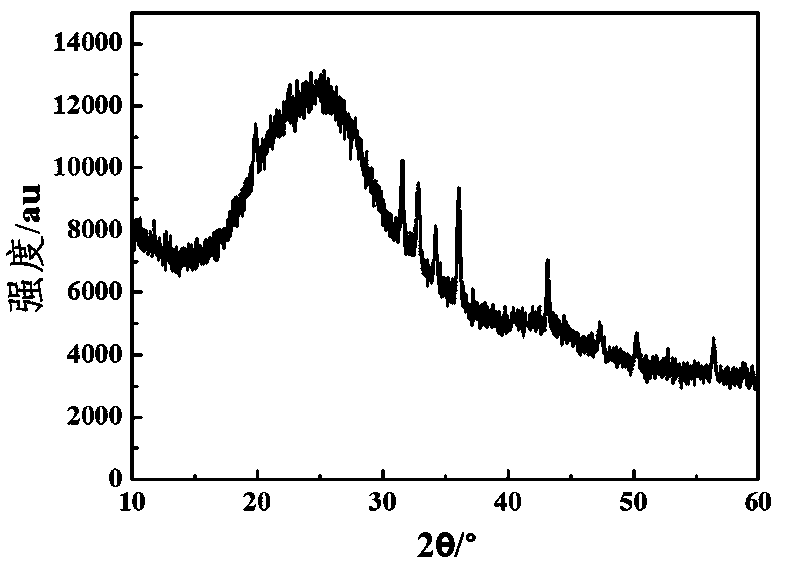

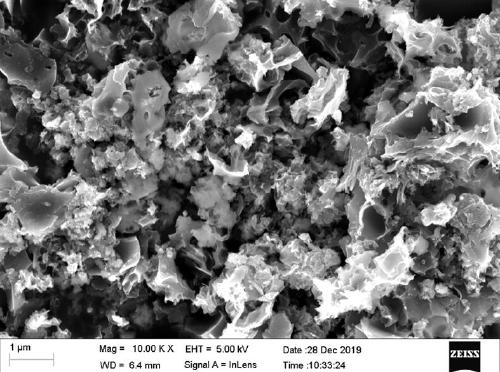

[0034] The photographs of the camellia oleifera shell used in this example and the crushed camellia oleifera shell powder are shown in Figure 1 and so on. The XRD spectrum pattern of gained camellia oleifera shell carbon powder material is as follows figure 2 It can be seen from the figure that the XRD spectrum of the sample prepared in this example (650°C) has an obvious carbon peak near 26°, which is basically consistent with the porous carbon spectrum in the existing literature, proving that the carbon powder material was prepared. image 3 Be the scanning electron micrograph of the camellia oleifera shell carbon powder material obtained in this embodiment, from image 3 It can be seen that the carbon powder has a very irregular surface and the existence of holes, which proves that the carbon powder we prepared does have a porous structure. from Figure 4 Analysis, at 3439cm -1 There is a strong and broad absorption peak at the position corresponding to the stretching a...

Embodiment 3

[0037] (3) Calculated according to the mass ratio, the obtained carbon powder: KOH ratio is 1:4. After being evenly ground, it is placed in a porcelain boat and placed in a tube furnace. Under the protection of Ar, it takes 115 minutes from room temperature to the firing temperature of 700 ℃, roasted for 2 hours, then started the cooling program and continued to ventilate, and cooled to room temperature. The burnt sample was fully washed with water, and dried in an oven at 60° C. for 24 hours to obtain camellia oleifera shell carbon powder material. Example 3 A camellia oleifera shell carbon powder material in this example, the specific preparation steps are as follows:

[0038] (1) Mechanically grinding camellia oleifera shells into powder;

[0039] (2) Calculated according to the mass ratio, the ratio of camellia oleifera shell powder: water is 1:30, weigh 2 g of camellia oleifera shell powder and 60ml of water, pour them into a beaker, and place the beaker in an ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com