Epoxy modified aliphatic amine curing agent and application thereof in fixing glue for silicon ingot cutting

A technology of epoxy modification and aliphatic amines, which is applied in the preparation of epoxy resin glue, organic compounds, adhesives, etc., can solve the problems of poisoning, poor impact resistance, weather resistance, and difficult curing, and reduce the risk of falling boards Probability, strong heat resistance, the effect of increasing colloidal hardness and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

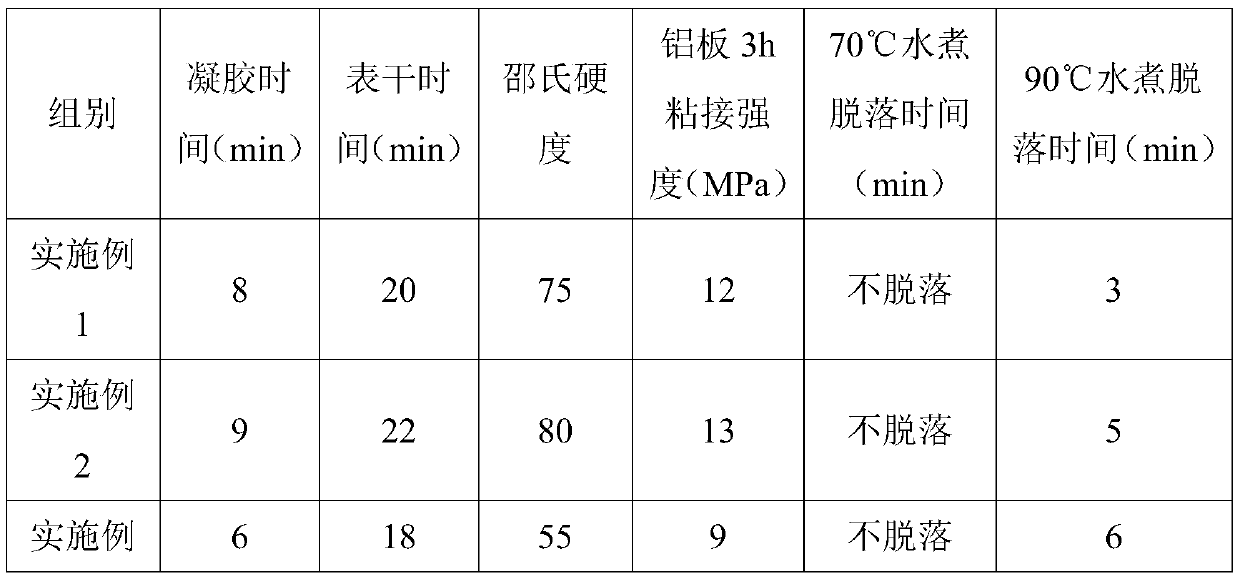

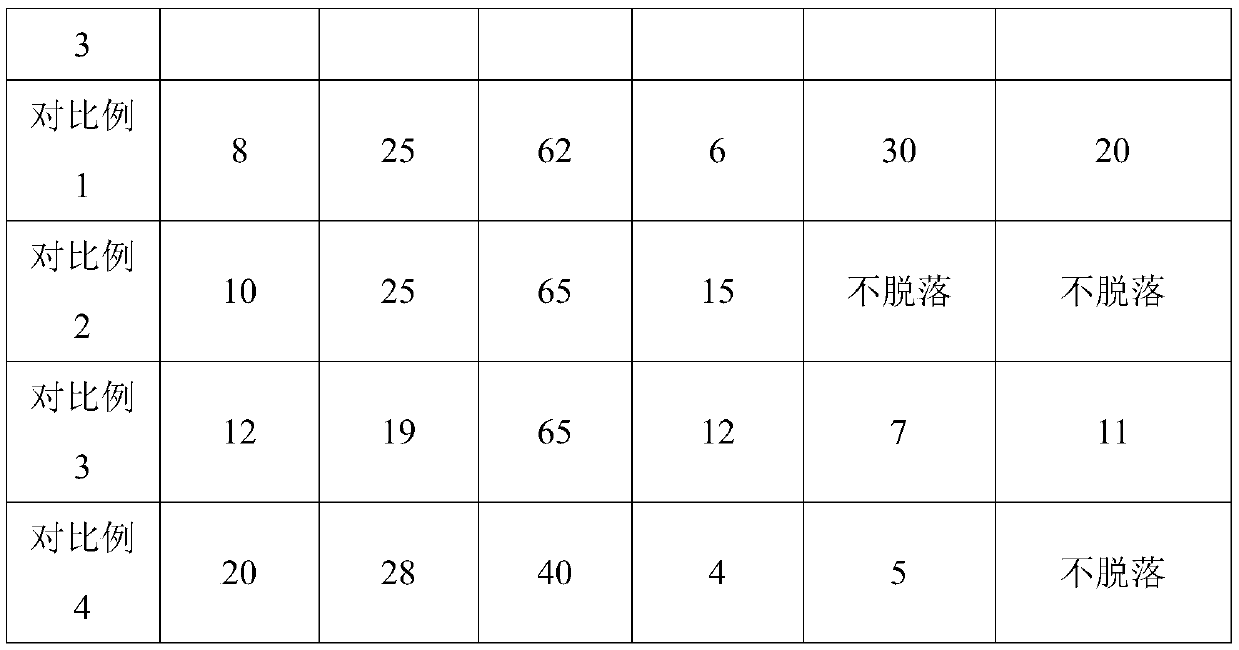

Embodiment 1

[0035] An epoxy-modified aliphatic amine curing agent, its raw materials include the following components by mass percentage: 10% of epoxy resin, 25% of active diluent, and 65% of polyamine.

[0036] The polyamine is triethylenetetramine.

[0037] The preparation method of epoxy modified fatty amine curing agent comprises the following steps: hydrogenated bisphenol A epoxy resin 2,2-bis(4-hydroxycyclohexyl) propane and reactive diluent AGE (C12-14 fatty glycidyl ether) Put it into the reaction kettle, raise the temperature to 40°C, then gradually add triethylenetetramine dropwise while stirring, continue to stir and raise the temperature to 60°C to keep the constant temperature for 2h, keep it under vacuum -0.1MPa for 1h to remove small molecules, and then check Product viscosity, amine value, reaction speed, hardness, bonding strength and other technical indicators.

[0038] An epoxy fixing glue, including A component and B component, A component includes: epoxy resin 55%, r...

Embodiment 2

[0047] An epoxy-modified aliphatic amine curing agent, its raw materials include the following components by mass percentage: 5% of epoxy resin, 15% of active diluent, and 50% of polyamine.

[0048] The polyamine is triethylenetetramine.

[0049] The preparation method of epoxy modified fatty amine curing agent comprises the following steps: hydrogenated bisphenol A epoxy resin 2,2-bis(4-hydroxycyclohexyl) propane and 690 (phenyl glycidyl ether) are dropped into the reactor, Raise the temperature to 40°C, then gradually add triethylenetetramine dropwise while stirring. After the dropwise addition, continue to stir and raise the temperature to 60°C and keep the constant temperature for 2h. Keep it under vacuum -0.1MPa for 0.5h to remove small molecules, and then check the viscosity of the product. Value, reaction speed, hardness, bonding strength and other technical indicators.

[0050] An epoxy fixing glue, including A component and B component, A component includes: epoxy re...

Embodiment 3

[0059] An epoxy-modified aliphatic amine curing agent, its raw materials include the following components by mass percentage: 15% of epoxy resin, 30% of reactive diluent, and 70% of polyamine.

[0060] The polyamine is triethylenetetramine.

[0061] The preparation method of epoxy modified fatty amine curing agent comprises the following steps: hydrogenated bisphenol A epoxy resin 4,4'-(1-methylethylene) bicyclohexanol and D-691 propylene oxide o-tolyl ether Put it into the reaction kettle, raise the temperature to 40°C, then gradually add triethylenetetramine dropwise while stirring, continue to stir and raise the temperature to 60°C for 2 hours at a constant temperature, keep it under vacuum -0.1MPa for 2 hours to remove small molecules, and then check Product viscosity, amine value, reaction speed, hardness, bonding strength and other technical indicators.

[0062] An epoxy fixing adhesive, including A component and B component, A component includes: 80% epoxy resin, 10% r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel time | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com