Method for preparing highly ordered silver nanochain structure based on low temperature plasma

A low-temperature plasma, highly ordered technology, applied in nanotechnology, nanotechnology, nano-optics, etc. for materials and surface science, can solve problems such as evaporation of metal nanowires, with a wide range, easy operation, and good reproducibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Clean the silicon wafer: soak the silicon wafer in analytical pure acetone for 2 minutes at room temperature, put the silicon wafer soaked in acetone into an ultrasonic container filled with deionized water, and clean it for 5 minutes; The ultrasonically treated silicon wafers are subjected to surface scratch treatment until the surface roughness is less than 1nm; the silicon wafers after the scratch treatment are placed in 7% hydrofluoric acid aqueous solution, soaked for 5-10 minutes, and the hydrofluoric acid aqueous solution is treated Soak the silicon wafers in an ultrasonic container filled with deionized water, wash them for 3 to 5 minutes to obtain silicon wafers with clean surfaces, blow dry the silicon wafers with nitrogen gas, and store them in a desiccator; the CP4A lotion is A composition prepared by mass fraction of 40% hydrofluoric acid aqueous solution, acetic acid, 65%-68% nitric acid aqueous solution and ultrapure water according to the volume ratio ...

Embodiment 2

[0027] Steps a-d are the same as in Example 1, the difference is to increase the steps:

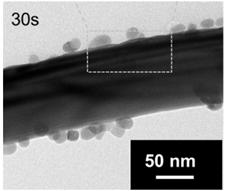

[0028] e: Low-temperature plasma bombardment: domestic CVD tube furnace is used, equipped with 250W RF power supply at the same time, RF frequency is 13.56 MHZ, the sample is placed in the tube furnace, the Ar atmosphere pressure is 0.2Pa, the RF power is 60W, and the processing time 3min. During the bombardment process, ensure that the "quasi-liquid" temperature of the one-dimensional silver nanowires is lower than its melting point. For the convenience of characterization, ensure that the surface temperature of the silicon wafer is lower than 100°C during the bombardment process.

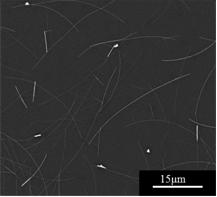

[0029] f. scan the silicon wafer after step e with an electron microscope to obtain the following figure 2 As shown in the layout diagram, it can be seen that after the one-dimensional silver nanowires are bombarded by low-temperature plasma, the silver nanowires gain kinetic energy, and in the "quasi-liquid...

Embodiment 3-6

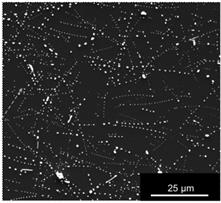

[0031] Step a is the same as in Example 2, and the average diameter and average length of the one-dimensional silver nanowires used in the preparation of one-dimensional silver nanowire suspensions in step b are listed in the table below, and then added to ultrasonic containers filled with ethanol , the mass ratio of silver nanowires to ethanol is 1:1000, and the power density is 0.5W / cm 3 disperse under ultrasonic for 5 minutes to obtain 4 different silver nanowire suspensions, and then go through steps c-f respectively to obtain Figure 4a As shown in the layout diagram, Figure 4b The statistical line graph of nanochain diameter and lattice period shown:

[0032]

[0033] Depend on image 3 It can be seen that the lattice period of the nanoparticles constituting the nanochains is only related to the diameter of the nanowires, and the smaller the diameter of the silver nanowires, the higher the order of the silver nanochains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com