Myopia-preventing paper and preparation method thereof

A technology of short-sighted paper and broken pulp, applied in the field of papermaking, can solve problems such as difficult to meet, increase production costs, difficulty in paper recycling and waste water treatment, strength, smoothness, whiteness, poor sizing performance, etc. , to achieve the effect of saving cost, preventing young people from myopia and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

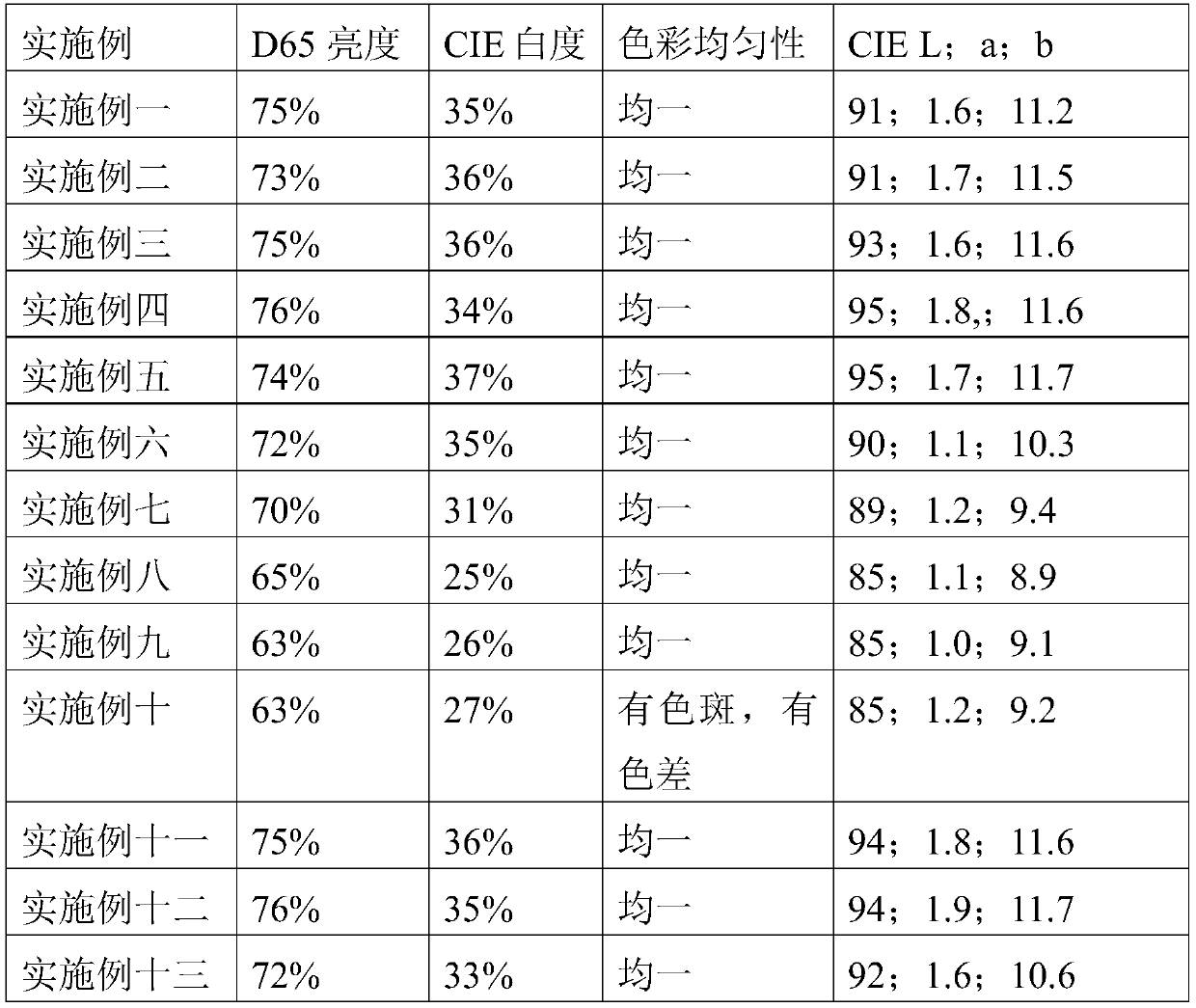

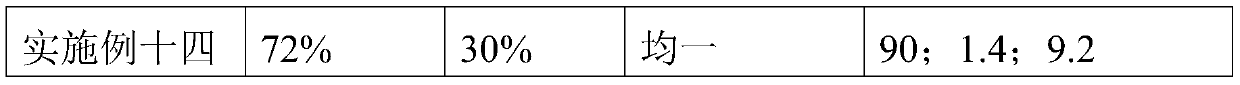

Embodiment 1

[0048] For the anti-myopia paper described in this embodiment, the raw materials for preparation include pulp and papermaking chemicals, wherein, calculated in parts by mass, the pulp includes: 32 parts of softwood pulp, 12 parts of hardwood pulp, and 30 parts of poplar APMP pulp 10 parts of broken paper pulp; calculated according to the number of parts by mass, every 100 parts of pulp is added with papermaking chemicals, including: 0.6 parts of cationic starch in the wet end, 0.02 parts of polyacrylamide, 0.2 parts of bentonite, 0.035 parts of organic micropolymers, alkenyl amber 0.05 parts of acid anhydride, 0.009 parts of liquid yellow dye 3GN-Z, 20 parts of calcium carbonate.

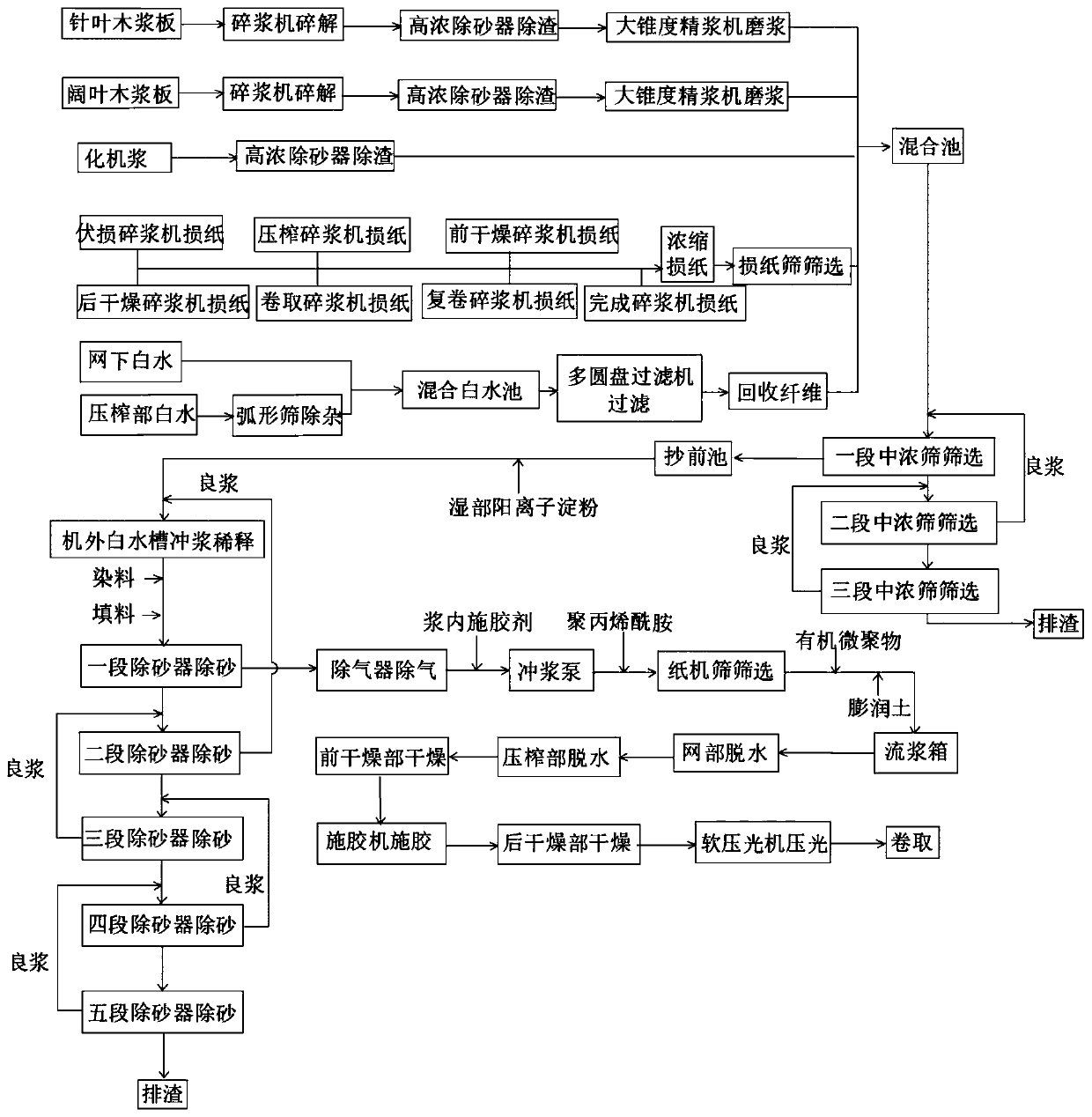

[0049] Such as figure 1 Shown, the preparation method of the anti-myopia paper described in the present embodiment may further comprise the steps:

[0050] S1. pulping, comprising the following steps:

[0051] S101. Disintegrate the coniferous wood pulp through a pulper, then remove slag through a...

Embodiment 2

[0066] For the anti-myopia paper described in this embodiment, the raw materials for preparation include pulp and papermaking chemicals, wherein, calculated in parts by mass, the pulp includes: 43 parts of softwood pulp, 28 parts of hardwood pulp, and 50 parts of poplar APMP pulp , Broken paper pulp 30 parts; Calculated according to the number of parts by mass, every 100 parts of pulp added to papermaking chemicals include: 1.2 parts of cationic starch in the wet end, 0.07 parts of polyacrylamide, 0.45 parts of bentonite, 0.12 parts of organic micropolymer, alkylene Ketone dimer 2.5 parts, liquid yellow dye 3GN-Z 0.025 parts, calcium carbonate 35 parts.

[0067] The preparation method of the anti-myopia paper described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0069] For the anti-myopia paper described in this embodiment, the raw materials for preparation include pulp and papermaking chemicals, wherein, calculated in parts by mass, the pulp includes: 35 parts of softwood pulp, 20 parts of hardwood pulp, and 40 parts of poplar APMP pulp , broken paper pulp 20 parts; calculated according to the number of parts by mass, every 100 parts of pulp added papermaking chemicals include: 1 part of cationic starch in the wet end, 0.05 part of polyacrylamide, 0.3 part of bentonite, 0.07 part of organic micropolymer, alkenyl amber 0.1 part of acid anhydride, 0.01 part of liquid yellow dye 3GN-Z, 30 parts of calcium carbonate.

[0070] The preparation method of the anti-myopia paper described in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com