Rhododendron molle diterpene effective part as well as preparation process method and application thereof

A technology of effective parts and preparation process, which is applied in the research field of anti-rheumatoid arthritis drug use, can solve the problems of limited clinical use, high toxicity, and lack of suitable quality control standards for the content of diterpenoids, and achieves convenient The effect of industrial production, low toxicity and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

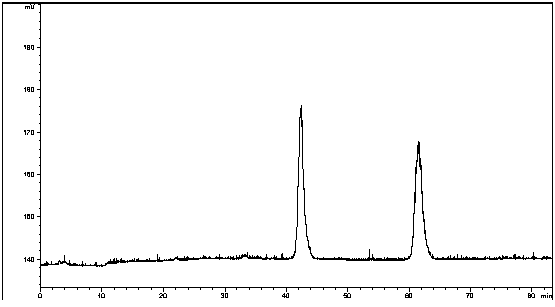

Image

Examples

Embodiment 1

[0039] Take 200 g of dried fruit of Rhododendron molle G. Don, add 8 times the volume of 70% ethanol to heat and reflux for extraction three times, each time for 2 hours, the extraction temperature is 60°C, combine the extracts, and concentrate to 10% ethanol concentration After standing still for 12 hours, centrifuge at 4000 rpm, centrifuge for 8 min, take the supernatant and put it on the macroporous resin column. times the column volume per hour, the elution flow rate is 4 times the column volume per hour, the diameter-to-height ratio is 1:10, eluted with pure water for 5 times the column volume, and 30% ethanol for 7 times the column volume, and collected diterpene-containing The sample is concentrated to obtain the extract of the effective part of the diterpene of A. chinensis, and the extract is mixed with the normal phase silica gel. The mass ratio of the extract and the sample normal phase silica gel is 1:2, and the normal phase silica gel column is put on. The mass ra...

Embodiment 2

[0041] Take 7 kg of dry fruit of Rhododendron molle G. Don, add 10 times the volume of 95% ethanol to heat and reflux to extract twice, each time for 3 hours, the extraction temperature is 80°C, combine the extracts, concentrate until there is no ethanol smell Stand still for 8 hours, centrifuge at 7000 rpm, and centrifuge for 14 min, take the supernatant and put it on a macroporous resin column, the loading amount is 1 kg of mulberry fruit / kg macroporous resin, and the loading flow rate is 4 times The column volume is 1 hour, the elution flow rate is 2 times the column volume per hour, and the diameter-to-height ratio is 1:7, followed by elution with pure water for 3 times the column volume, 20% ethanol for 10 times the column volume, and collecting diterpene-containing The sample is concentrated to obtain the extract of the effective part of the diterpene of A. chinensis. The extract is mixed with the normal phase silica gel. The mass ratio of the extract and the normal phase...

Embodiment 3

[0043] Take 12 kg of dry fruit of Rhododendron molle G. Don, add 5 times the volume of 70% ethanol to heat and reflux for extraction 4 times, each time for 1 hour, the extraction temperature is 50°C, combine the extracts, concentrate until there is no ethanol smell Stand still for 10 hours, filter with a 300-mesh sieve, take the filtrate and put it on a macroporous resin column, the loading amount is 1.5 kg of Azalea fruit / kg macroporous resin, the loading flow rate is 3 times the column volume per hour, and the elution flow rate 3 times the column volume per hour, the diameter-to-height ratio is 1:5, sequentially eluted with pure water for 7 times the column volume, and 50% ethanol for 5 times the column volume, collected and concentrated the samples containing diterpene to obtain the diterpene For the active part extract, mix the extract with normal phase silica gel, the mass ratio of the extract and the normal phase silica gel is 1:3, put it on the normal phase silica gel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com