Indium zinc sulfide/bismuth vanadate composite material, and preparation method and application thereof

A composite material, indium zinc sulfide technology, applied in chemical instruments and methods, chemical/physical processes, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of redox potential limitation, high recombination probability, etc. Achieve the effect of promoting rapid migration, increasing specific surface area, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of decahedral bismuth vanadate

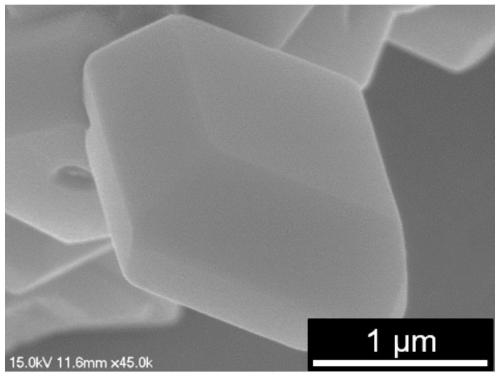

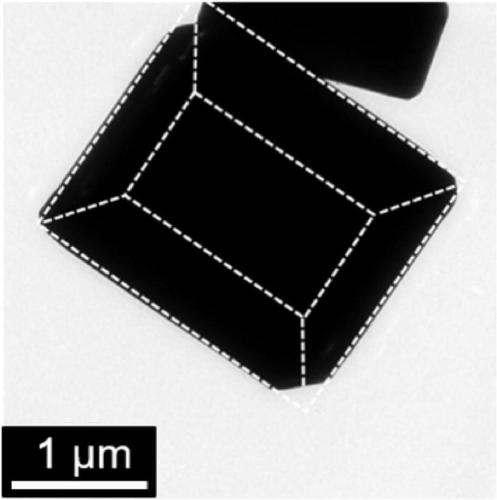

[0029] Disperse 3 grams of bismuth nitrate pentahydrate and 1 gram of ammonium vanadate into 50 milliliters of 3mol / L dilute nitric acid, adjust the pH to 3 by adding ammonia water dropwise until a precipitate is formed, and transfer the precipitate to a reactor for aging for 3 hours Afterwards, hydrothermal reaction was carried out at 250° C. for 20 hours. After the reaction, the product was washed four times with water and ethanol respectively, and dried in a vacuum oven for 8 hours to obtain decahedral bismuth vanadate. attached figure 1 And attached figure 2 They are the SEM image and TEM image of decahedral bismuth vanadate, respectively. It can be seen from the pictures that the bismuth vanadate presents a decahedral structure.

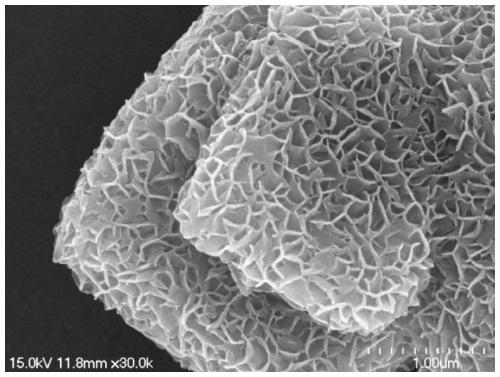

[0030] 2. Preparation of indium zinc sulfide / bismuth vanadate composites

[0031] Inject 30 milliliters of water and 3 milliliters of glycerin into a 50 milliliter round bottom flask, ad...

Embodiment 2

[0034] Disperse 20 mg of photocatalyst into 100 ml of mixed solution (the volume of water and triethanolamine is 9:1), and then add 3wt% H 2 PtCl 6 ·6H 2 O is used as a cocatalyst, and the mixed solution is ultrasonically dispersed to make it uniformly dispersed, and then degassed to discharge the air left in the photocatalytic system. Turn on a 300-watt xenon lamp to start the photolysis water experiment, take a sample every one hour, and use a gas chromatograph containing a thermal conductivity detector to detect the amount of hydrogen generated, wherein nitrogen is the carrier gas, using Molecular sieve columns.

[0035] attached Figure 5 The effect diagram of the photocatalytic decomposition of water to produce hydrogen by the indium zinc sulfide / bismuth vanadate composite material, attached Figure 6 The photocatalytic material recycling effect diagram. It can be seen from the figure that the photocatalytic performance of the indium zinc sulfide / bismuth vanadate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com