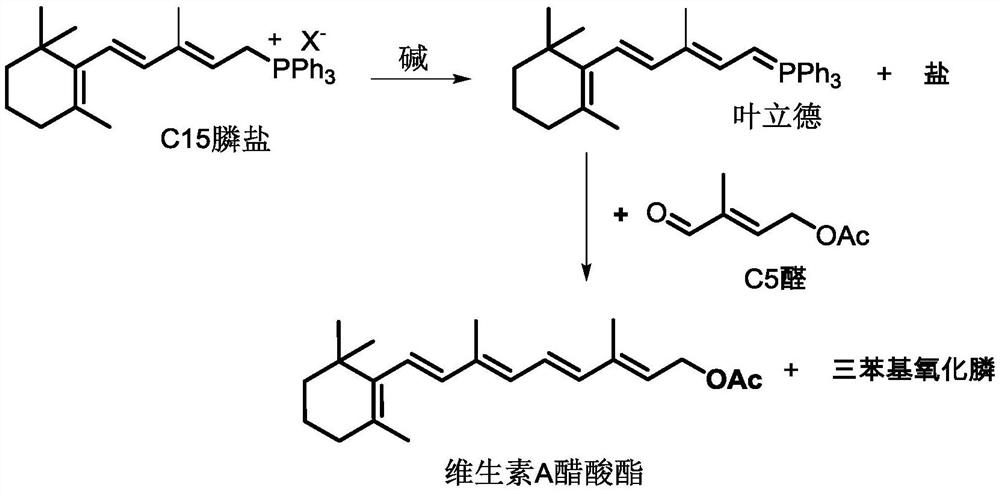

A device and method for preparing vitamin A acetate by multi-stage continuous series reaction extraction

A series reaction and extraction device technology, applied in the direction of organic chemistry, can solve the problems of increased side reactions, increased vitamin A acetate synthesis yield, high labor intensity, and difficulty in continuous operation, so as to reduce the labor intensity of process operations and improve industrial production level, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation raw material F 1 , wherein the mass content of C15 phosphonium chloride is 30.37%, the mass content of C5 aldehyde is 8.88%, and the mass content of water is 60.75% (the molar ratio of C5 aldehyde to C15 phosphine chloride is 1.03). raw material F 1 Preheat to 40°C.

[0059] Prepare lye F 2 , wherein the sodium carbonate mass concentration is 15%, and the phase transfer aid cetyltrimethylammonium chloride mass concentration is 3% (the mol ratio of sodium carbonate and cetyltrimethylammonium chloride is 15), The rest is pure water. Lye F 2 Preheat to 40°C.

[0060] Petroleum ether was selected as the extractant E 0 . Extractant E 0 Preheat to 40°C.

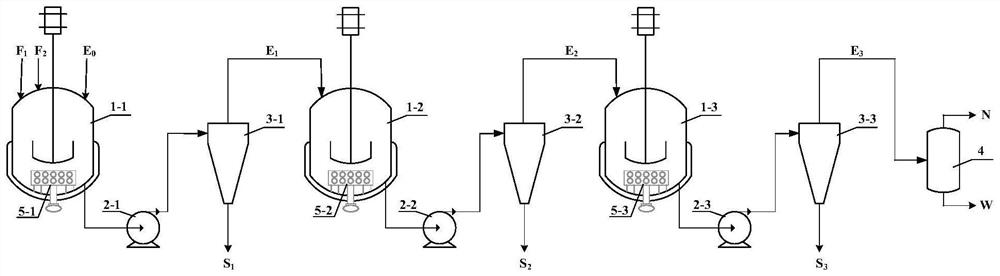

[0061] Reactor such as figure 1 As shown, the raw material F 1 , lye F 2 and extractant E 0 The mass flow rates of 14.8kg / min, 7.0kg / min and 7.4kg / min are simultaneously passed into the first-stage reaction extraction stirring tank 1-1 and maintained at 40°C for the reaction extraction process. When ...

Embodiment 2

[0063] Preparation raw material F 1 , wherein the mass content of C15 phosphine chloride is 15.77%, the mass content of C5 aldehyde is 5.37%, and the mass content of water is 78.86% (the molar ratio of C5 aldehyde to C15 phosphine chloride is 1.2). raw material F 1 Preheat to 55°C.

[0064] Prepare lye F 2 , wherein the mass concentration of sodium hydroxide is 35%, the mass concentration of phase transfer aid dodecyltrimethylammonium chloride is 6.4%, and all the other are pure water (sodium hydroxide and dodecyltrimethylammonium chloride The molar ratio is 36). Lye F 2 Preheat to 55°C.

[0065] Select n-heptane as extractant E 0 . Extractant E 0 Preheat to 55°C.

[0066] As shown in the attached figure, the raw material F 1 , lye F 2 and extractant E 0The mass flow rates of 38.0kg / min, 1.9kg / min and 9.4kg / min are simultaneously passed into the first-stage reaction extraction stirring tank 1-1 and maintained at 55°C for the reaction extraction process. When the li...

Embodiment 3

[0068] Preparation raw material F 1 , wherein the mass content of chloride C15 phosphine salt is 23.19%, the mass content of C5 aldehyde is 7.24% (the molar ratio of C5 aldehyde to chloride C15 phosphine salt is 1.1), and the water mass content is 69.57%. raw material F 1 Preheat to 50°C.

[0069] Prepare lye F 2 , wherein the mass concentration of potassium carbonate is 30%, the phase transfer aid cetyltrimethylammonium bromide mass concentration is 3.2%, and all the other are pure water (mole of potassium carbonate and cetyltrimethylammonium bromide than 25). Lye F 2 Preheat to 50°C.

[0070] Select n-hexane as extractant E 0 . Extractant E 0 Preheat to 50°C.

[0071] As shown in the attached figure, the raw material F 1 , lye F 2 and extractant E 0 The mass flow rates of 21.6kg / min, 5.5kg / min and 8.7kg / min are simultaneously passed into the first-stage reaction extraction stirring tank 1-1 and maintained at 50°C for the reaction extraction process. When the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com