Porous COFs block material and application thereof in isomer separation

A technology of isomers and monomers, which is applied in the separation of different isotopic elements, separation methods, and separation of dispersed particles, can solve the problems of high energy consumption and unsatisfactory separation effects, and achieve simple operation and avoid unsatisfactory The effect of controlled evaporation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of amphiphilic COFs particles

[0044] Add 0.708g (2mmol) 2,4,6-tris(4-aminophenyl)-1,3,5-triazine and 0.134g (1mmol) terephthalaldehyde to 20mL 1,2-dichlorobenzene and 20mL In the mixed solvent of trimethylbenzene, degassing treatment was carried out through three freeze-pump-thaw cycles. After the treatment, it was left to react in an oil bath at 120°C for 7 days. After the reaction, the precipitate was centrifuged and washed with anhydrous tetrahydrofuran. Extraction by Soxhlet extractor for 24 hours, and vacuum drying at 80° C. for 24 hours to obtain yellow amphiphilic COFs particles whose structural unit is represented by formula II (R=H).

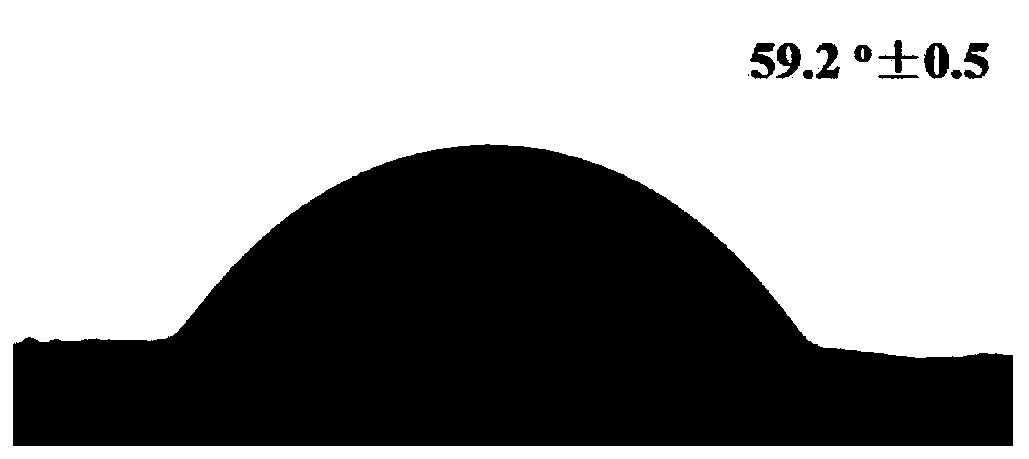

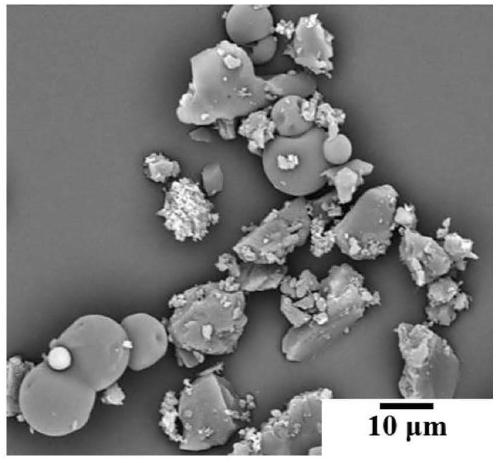

[0045] Scanning electron microscopy was performed on the obtained yellow amphiphilic COFs particles, and the results were as follows: figure 1 As shown, its microscopic morphology presents a spherical structure with a size distribution of 5-15 μm. Simultaneously, the yellow powder that obtains is carried out co...

Embodiment 2

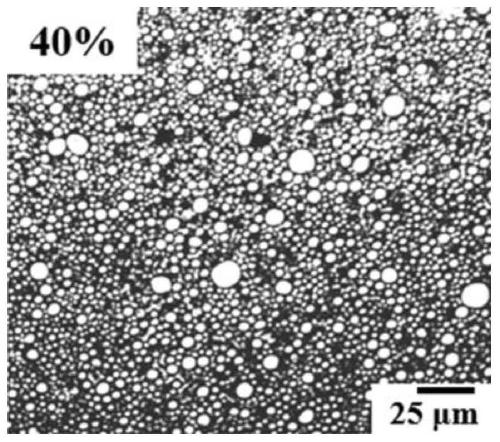

[0054] In step 2 of this example, at room temperature and a stirring speed of 11400 rpm, 17.5 mg of amphiphilic COFs particles were uniformly dispersed in 150 μL of 2% polyvinyl alcohol aqueous solution, and then added to 4 mg of amphiphilic cholesterol (n = 8) In 350 μL of mesitylene, the mixed solution obtained was fully mixed at a constant speed of 11400 rpm until a stable O / W type Pickering emulsion was formed, and the volume content of the aqueous phase in the gained Pickering emulsion was 30% (see Figure 10 ), the content of amphiphilic COFs particles is 0.035g / mL, and the content of amphiphilic cholesterol is 0.008g / mL. Other steps are identical with embodiment 1, obtain porous COFs bulk material (see Figure 11 ).

Embodiment 3

[0056] In step 2 of this example, at room temperature, 17.5 mg of amphiphilic COFs particles were uniformly dispersed in 250 μL of 2% polyvinyl alcohol aqueous solution at room temperature and at a stirring speed of 11400 rpm, and then added to a solution containing 4 mg In 250 μL mesitylene of amphipathic cholesterol (n=8), the mixed solution obtained is fully mixed at a constant speed of 11400 rpm until a stable O / W type Pickering emulsion is formed, and the volume content of the aqueous phase in the gained Pickering emulsion is 50%, the content of amphiphilic COFs particles is 0.035g / mL, and the content of amphiphilic cholesterol is 0.008g / mL. Other steps were the same as in Example 1 to obtain a porous COFs block.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com