Carbon quantum dot fluorescent double-network hydrogel and preparation method and application thereof

A carbon quantum dot and double network technology, applied in the field of carbon quantum dot fluorescent double network hydrogel and its preparation, can solve the problems of poor mechanical strength, limited application of fluorescent single network hydrogel, etc., and achieves good processing performance, optical Stable and efficient properties and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a carbon quantum dot fluorescent double network hydrogel is as follows:

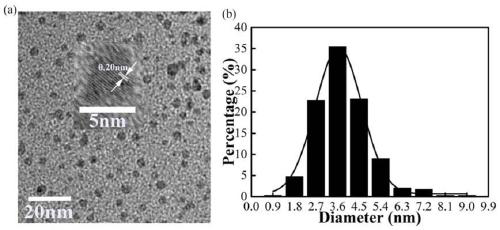

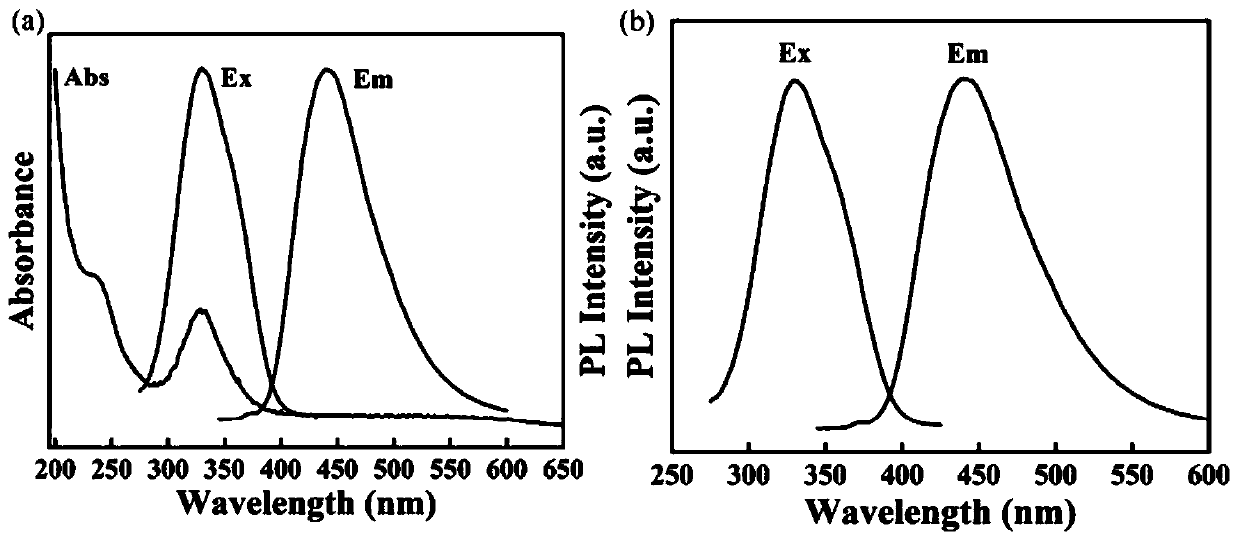

[0042](1) Preparation of nitrogen-doped carbon quantum dots: use citric acid monohydrate as the carbon source, urea as the nitrogen source, and the mass ratio of urea to citric acid monohydrate is 2:1. After one-step hydrothermal method, the reaction temperature is 120°C , the holding time is 6 hours, first filtered through a 0.22 μm filter membrane, then repeatedly dialyzed with deionized water, and freeze-dried to obtain particles with a particle size distribution of 1-10nm and a high quantum yield, that is, the quantum yield is greater than 17%. Nitrogen-doped carbon quantum dots (N-CDs).

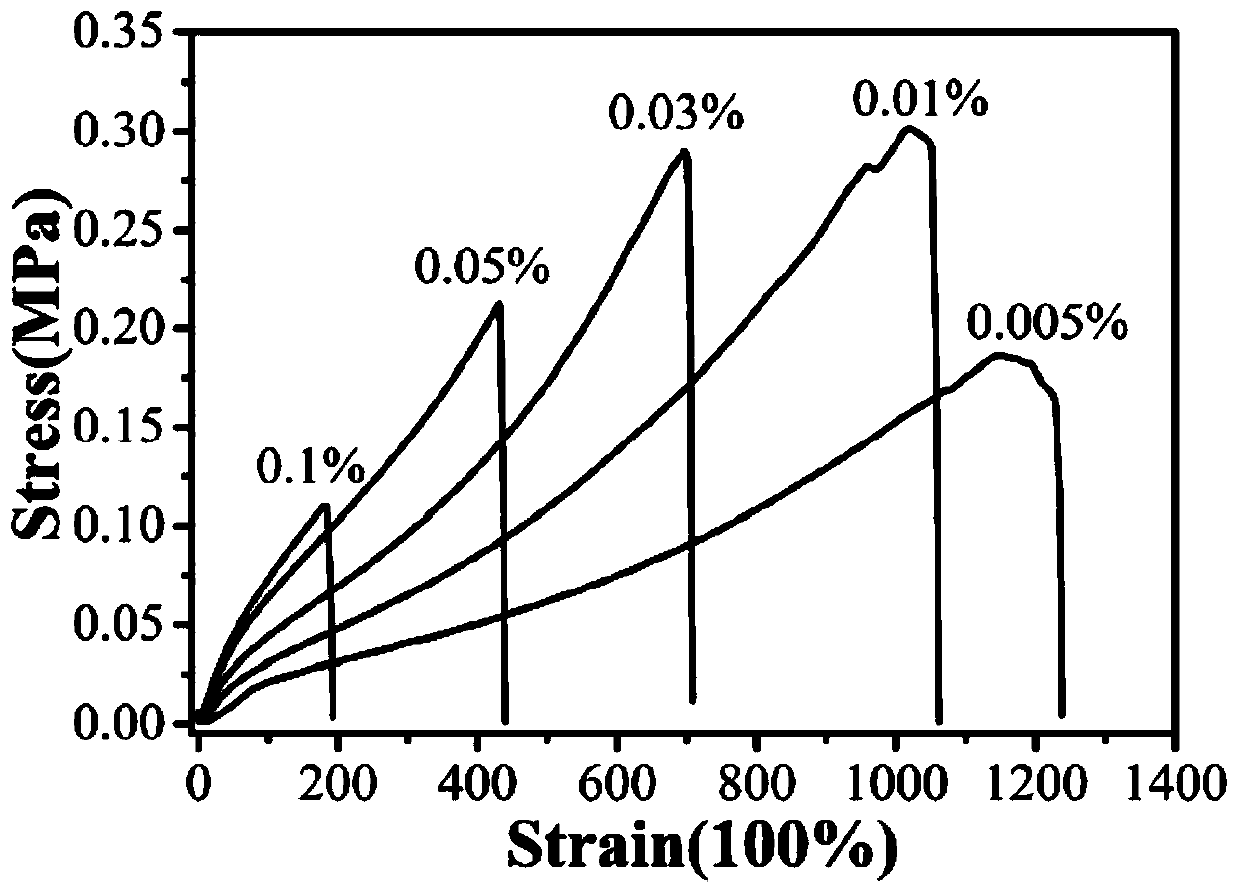

[0043] (2) Preparation of agar / polyacrylamide / nitrogen-doped carbon quantum dots (Agar / PAAM / N-CDs) fluorescent double network hydrogel: (a) prepare acrylamide solution with a monomer concentration of 4mol / L respectively and the agar mixture with a monomer concentration of 20mg / mL, the...

Embodiment 2

[0049] A method for preparing a carbon quantum dot fluorescent double network hydrogel is as follows:

[0050] (1) Preparation of nitrogen-doped carbon quantum dots: use citric acid monohydrate as the carbon source, urea as the nitrogen source, and the mass ratio of urea to citric acid monohydrate is 2:1. After one-step hydrothermal method, the reaction temperature is 120°C , the holding time is 6 hours, first filtered through a 0.22 μm filter membrane, then repeatedly dialyzed with deionized water, and freeze-dried to obtain particles with a particle size distribution of 1-10nm and a high quantum yield, that is, the quantum yield is greater than 17%. Nitrogen-doped carbon quantum dots (N-CDs).

[0051] (2) Preparation of agar / polyacrylamide / nitrogen-doped carbon quantum dots (Agar / PAAM / N-CDs) fluorescent double network hydrogel: (a) prepare acrylamide solution with a monomer concentration of 4mol / L respectively and the agar mixture with a monomer concentration of 20mg / mL, th...

Embodiment 3

[0055] A method for preparing a carbon quantum dot fluorescent double network hydrogel is as follows:

[0056] (1) Preparation of nitrogen-doped carbon quantum dots: use citric acid monohydrate as the carbon source, urea as the nitrogen source, and the mass ratio of urea to citric acid monohydrate is 2:1. After one-step hydrothermal method, the reaction temperature is 120°C , the holding time is 6 hours, first filtered through a 0.22 μm filter membrane, then repeatedly dialyzed with deionized water, and freeze-dried to obtain particles with a particle size distribution of 1-10nm and a high quantum yield, that is, the quantum yield is greater than 17%. Nitrogen-doped carbon quantum dots (N-CDs).

[0057] (2) Preparation of agar / polyacrylamide / nitrogen-doped carbon quantum dots (Agar / PAAM / N-CDs) fluorescent double network hydrogel: (a) prepare acrylamide solution with a monomer concentration of 4mol / L respectively and the agar mixture with a monomer concentration of 20mg / mL, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com