Preparation process of multifunctional calotropis gigantea fiber blended fabric

A technology of croissant melon fiber and blended fabrics, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc. It can solve problems such as pollution and poor environment, and achieve the effects of simple process operation, soft hand feeling, and soft air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

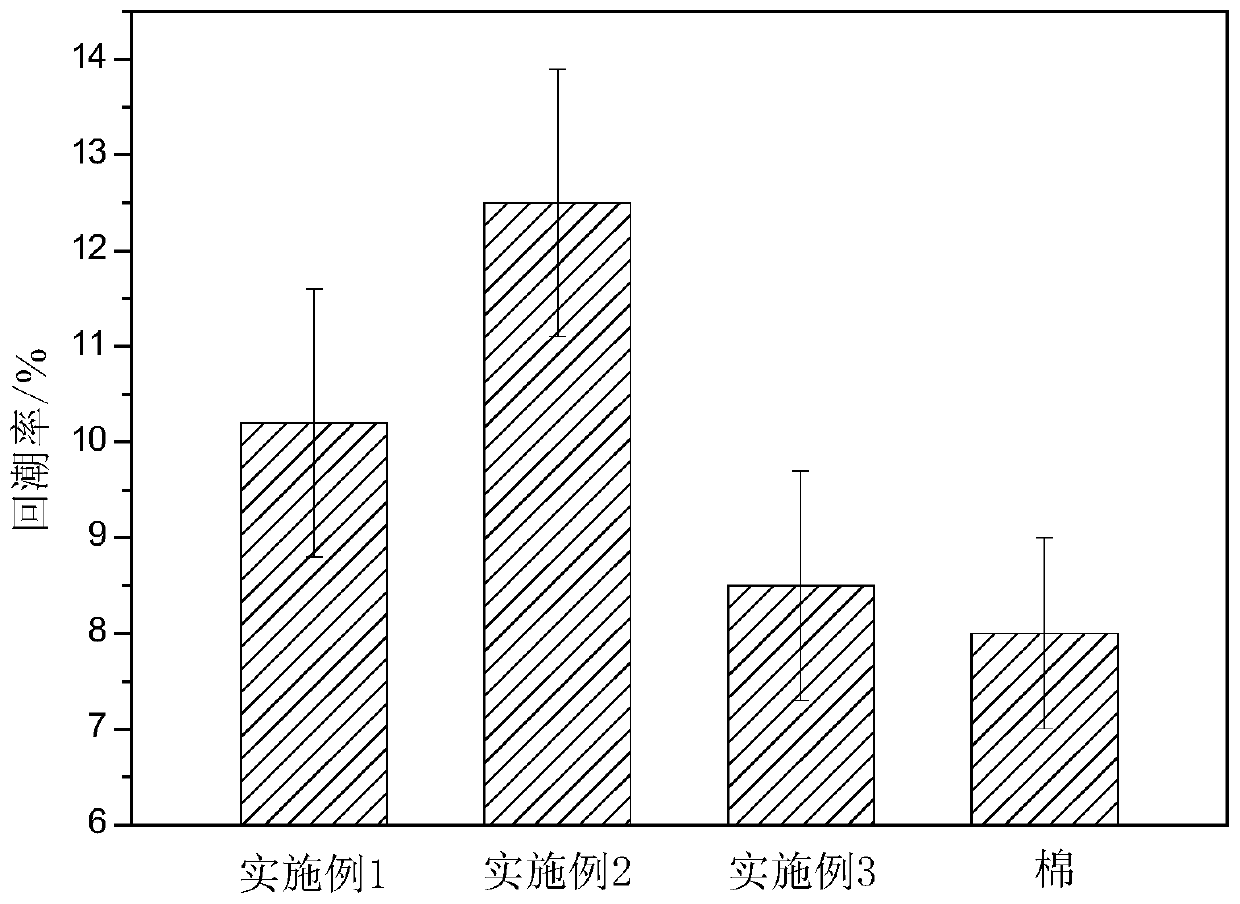

[0044]S1, preparation of horn melon fiber blended fabric: cotton fiber is spun into combed sliver, combed sliver and horn melon fiber are mixed according to mass ratio (1-9):(1-9), obtain mixture A; Then adopt one of the weaving methods of ring spinning, compact spinning or rotor spinning to weave the mixture A to obtain the melon fiber blended fabric;

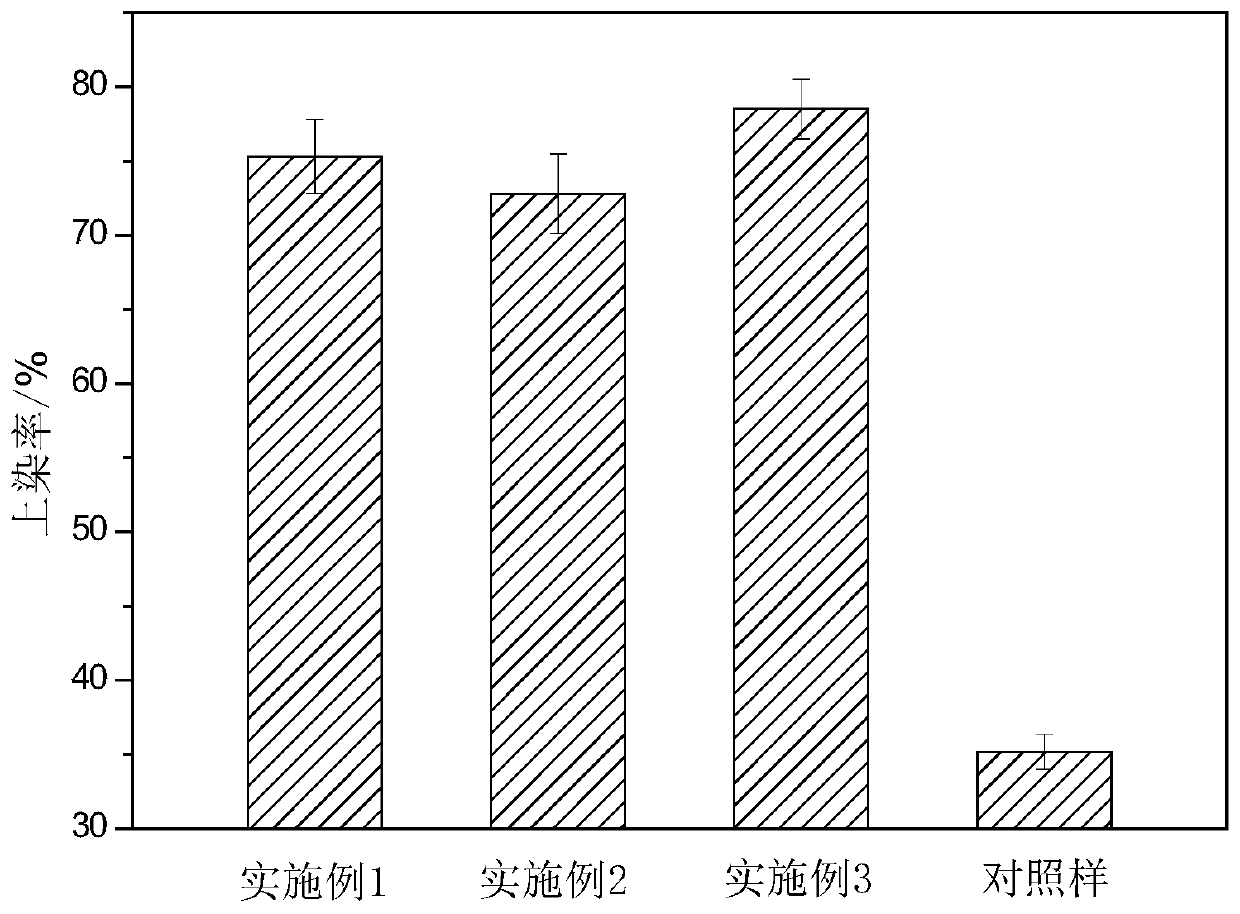

[0045] S2, low-temperature plasma treatment: place the horn gourd fiber blended fabric in deionized water to clean for 10-20min, put it into a low-temperature plasma treatment device after drying; use air, oxygen, nitrogen or argon to the horn gourd fiber blended fabric Perform plasma treatment for a treatment time of 1-10 minutes to obtain a surface-treated horn gourd fiber blended fabric; wherein, the power of the plasma treatment is 20-240W;

[0046] S3. Antibacterial dyeing and finishing of croissant melon fiber blended fabric:

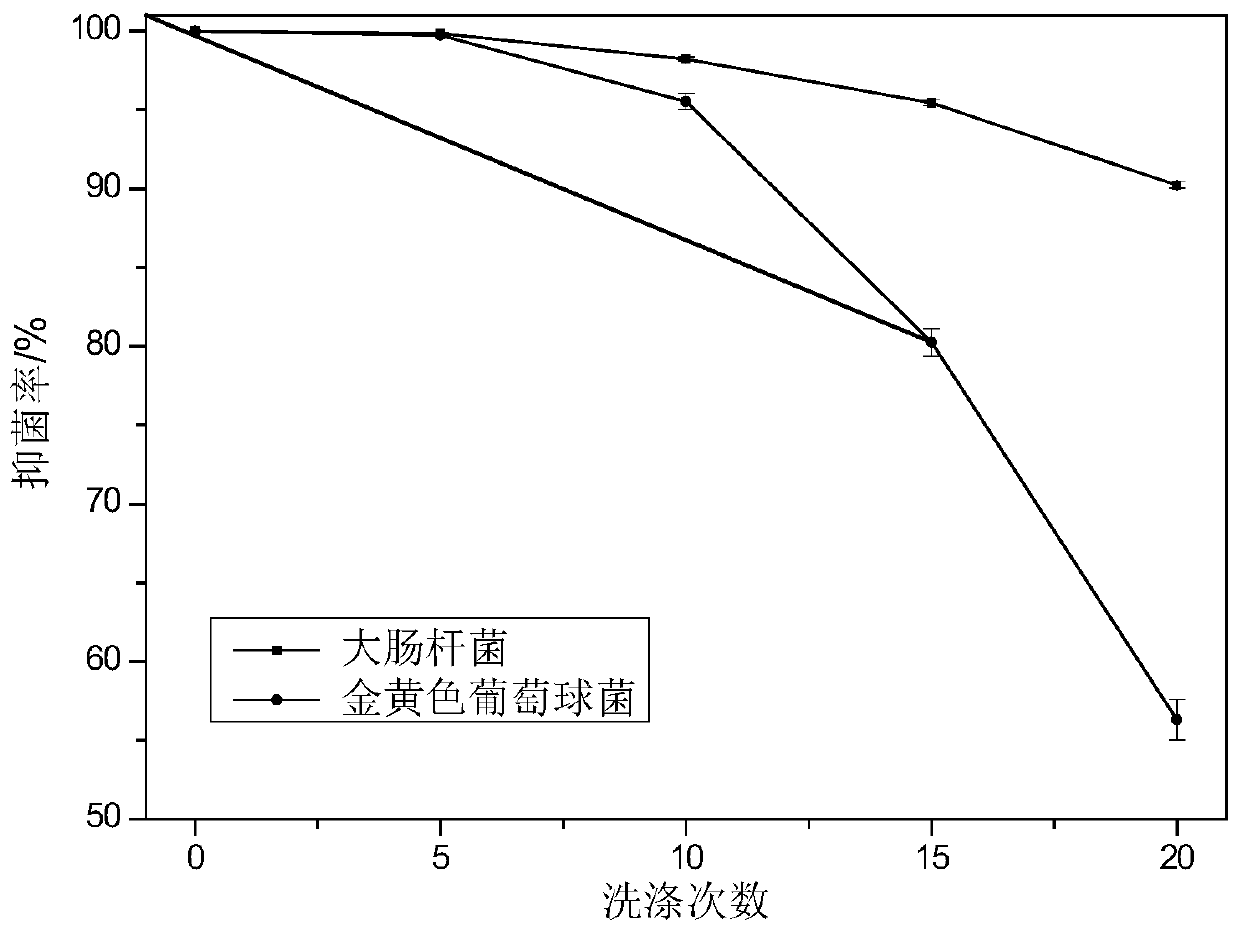

[0047] Place the surface-treated croissant melon fiber blended fabric in the silk fibroin nan...

Embodiment 1

[0060] Prepare the multifunctional croissant melon fiber blended fabric of iron yellow, comprising the following steps:

[0061] Ring-spinning is used to spin out the blended fabric of horned melon fiber and combed sliver, wherein the mass ratio of horned melon fiber and combed sliver is 3:7, and the yarn count is 32 blended fabrics of horned melon fiber; Put the horn gourd fiber blended fabric in deionized water and wash it for 20 minutes, put it into a low-temperature plasma treatment device after drying, and use air to carry out plasma treatment on the horn gourd fiber blended fabric, the processing power is 80W, and the processing time is 600s;

[0062] Preparation of silk fibroin nano-silver antibacterial functional finishing agent: soak degummed silk in 9.7mol / L lithium bromide solution, place it in a vacuum drying oven at 60°C for 4 hours, shake it every 1 hour, and dilute it to prepare a concentration of 1%. silk fibroin solution, add 4mg / mL AgNO 3 crystal powder to o...

Embodiment 2

[0066] Prepare the multifunctional croissant melon fiber blended fabric of fuchsia, comprising the following steps:

[0067] Preparation of horn gourd fiber blended fabric: the blended fabric of horn gourd fiber and combed sliver is spun by compact spinning process, wherein the mass ratio of horn gourd fiber and combed sliver is 4:6, and the yarn count is 21 The croissant melon fiber blended fabric;

[0068] Low-temperature plasma treatment: wash the croissant melon fiber blended fabric in deionized water for 20 minutes, dry it and put it in a low-temperature plasma treatment device, use air to perform plasma treatment on the croissant melon fiber blended fabric, the processing power is 240W, and the processing time 60s;

[0069] Preparation of silk fibroin nano-silver antibacterial functional finishing agent: soak degummed silk in 8.4mol / L lithium bromide solution, place it in a vacuum drying oven at 80°C for 6 hours, shake once every 1 hour, and dilute it to prepare a conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com