Preparation method of surface-dispersed nanometer bismuth molybdate composite photocatalytic material

A composite photocatalytic and dispersive technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Surface area, increased active sites, beneficial to recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a surface-dispersed nanometer bismuth molybdate composite photocatalyst material, comprising the following steps:

[0029] (1) Preparation of titanium-containing precursor solution: Add 5 to 30 parts by mass of at least one of polyvinylpyrrolidone, polyimide, and polylactic acid and polyacrylonitrile accounting for 40 to 60% of the mass fraction of the mixture 50-100 parts by mass of ethanol, N,N-dimethylformamide, and at least one solvent of propylene glycol methyl ether, and magnetically stirred for 0.5-2 hours to mix them uniformly to obtain a clear and transparent polymer solution. Adding 1-5 parts by mass of acetic acid and 1-10 parts by mass of butyl titanate solution dropwise into the polymer solution, stirring continuously to make it uniform and transparent, to obtain a titanium-containing precursor solution.

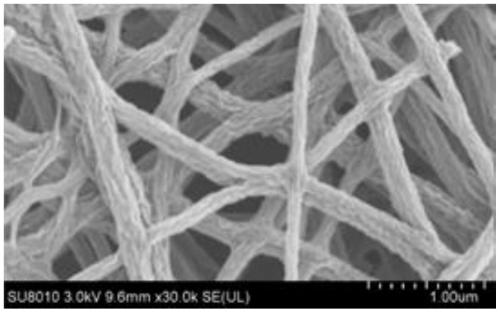

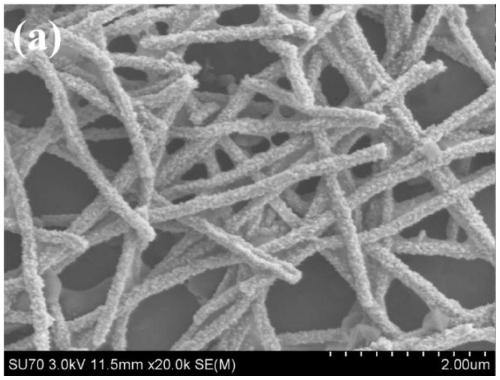

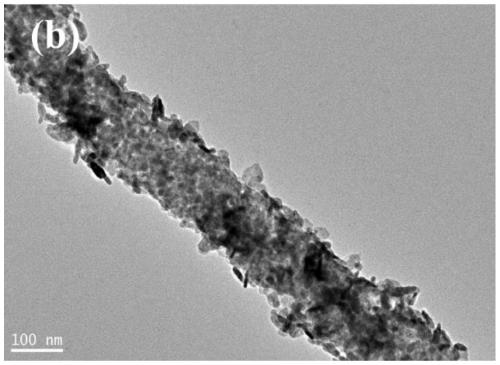

[0030] (2) Preparation of titanium dioxide nanofibers: the titanium-containing precursor solution was passed through an electrospi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com