A pH-responsive amphiphilic-strong polarity intelligent switching emulsion and its preparation

A strong polarity, emulsion technology, applied in the preparation of organic compounds, the preparation of carboxylic acid amides, the preparation of amino compounds, etc., can solve the problems of surfactant residue, oil phase turbidity, affecting oil phase quality and use effect, etc. achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

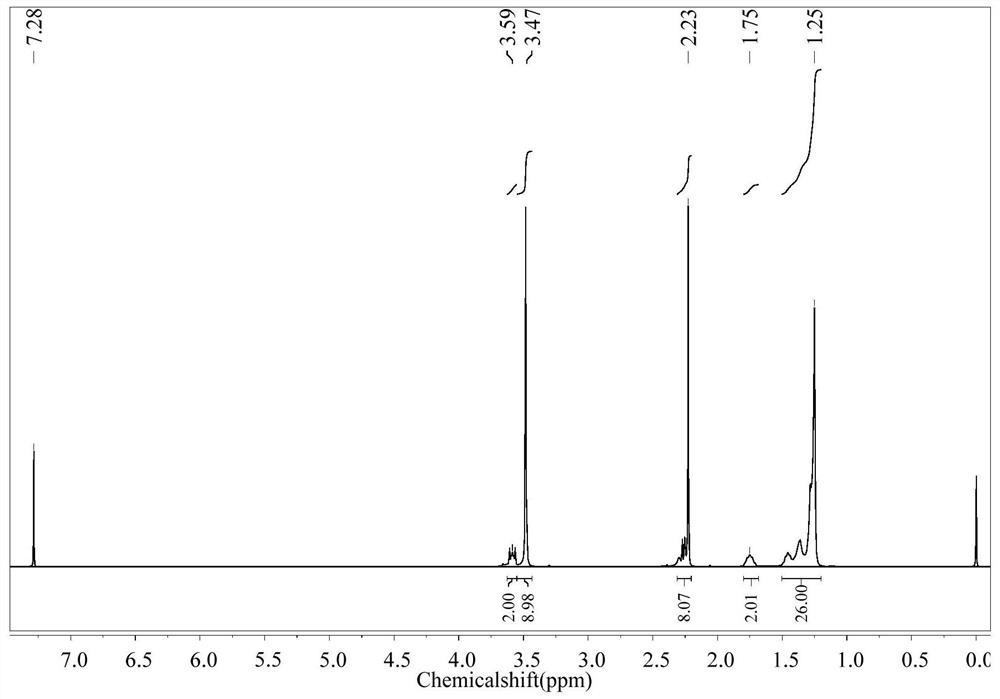

[0046] Embodiment 1: the preparation of tensio-active agent (N-C 16 -N + )

[0047]

[0048] (1) Acid chlorination reaction: Add hexadecanedioic acid (25g, 0.087mol) solid into a three-necked flask equipped with a device for absorbing tail gas and a condenser return pipe, and add a small amount of N,N-dimethylformamide as Catalyst, slowly dropwise add thionyl chloride (26g, 0.22mol). Set the reaction temperature to 60°C, react for 1 h, and remove excess thionyl chloride by rotary evaporation under reduced pressure to obtain product 1.

[0049] (2) Amidation reaction: Place dimethylamine aqueous solution (154g, 1.37mol) in an ice-water bath, add 1 (25g, 0.077mol) of dichloromethane solution dropwise, react for 2 hours after completion, and then dilute the reaction solution with two Chloromethane was extracted 5 times, and the combined extracts were washed with anhydrous Na 2 SO 4 The excess water was removed, the filtrate was obtained by suction filtration, the filtrate...

Embodiment 2

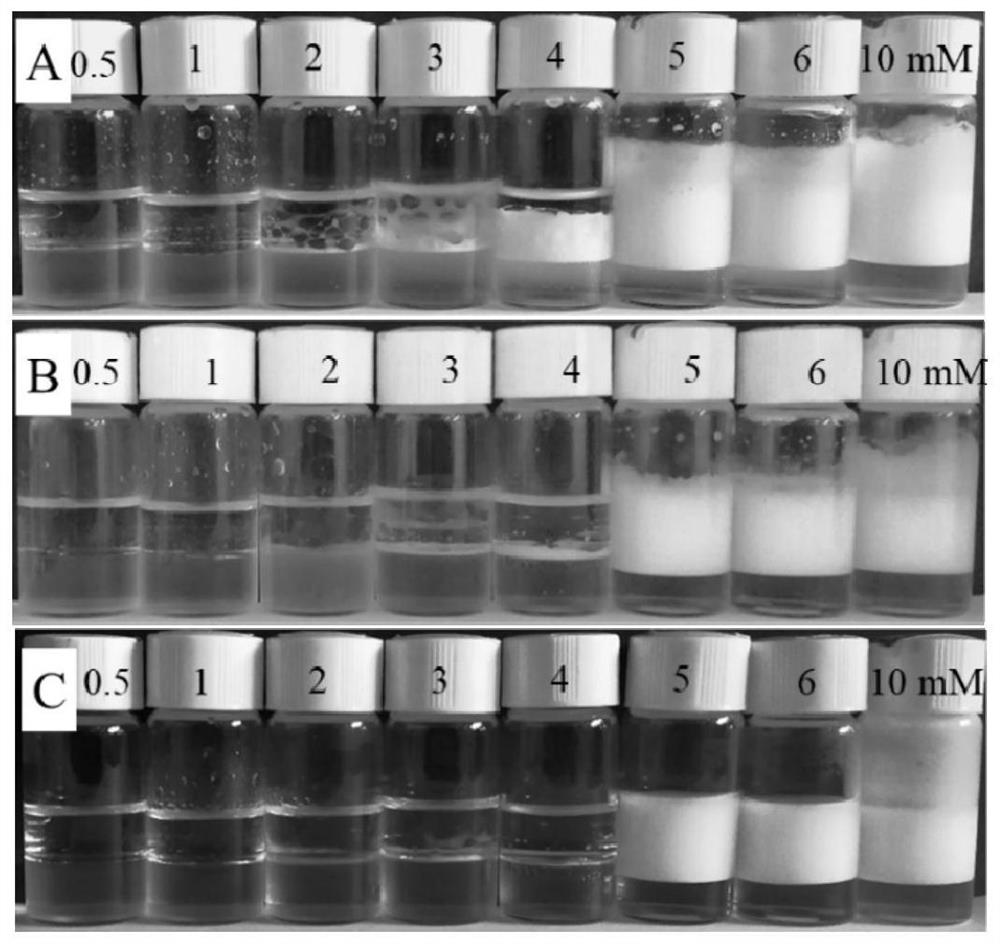

[0053] Embodiment 2: preparation emulsion

[0054] Surfactant N-16-N synthesized with embodiment 1 + Prepare a series of aqueous solutions of different concentrations (0.5mM, 1mM, 2mM, 3mM, 4mM, 5mM, 6mM, 10mM,), respectively take 7mL and add them to a 25mL vial, add 7mL of n-decane, homogenize with a high shear homogenizer After mass emulsification for 2 minutes, a stable O / W emulsion was obtained.

[0055] The result is as image 3 As shown, when the concentration of the emulsion is 5mM, the emulsion can be stabilized for one month without demulsification, and has good stability.

Embodiment 3

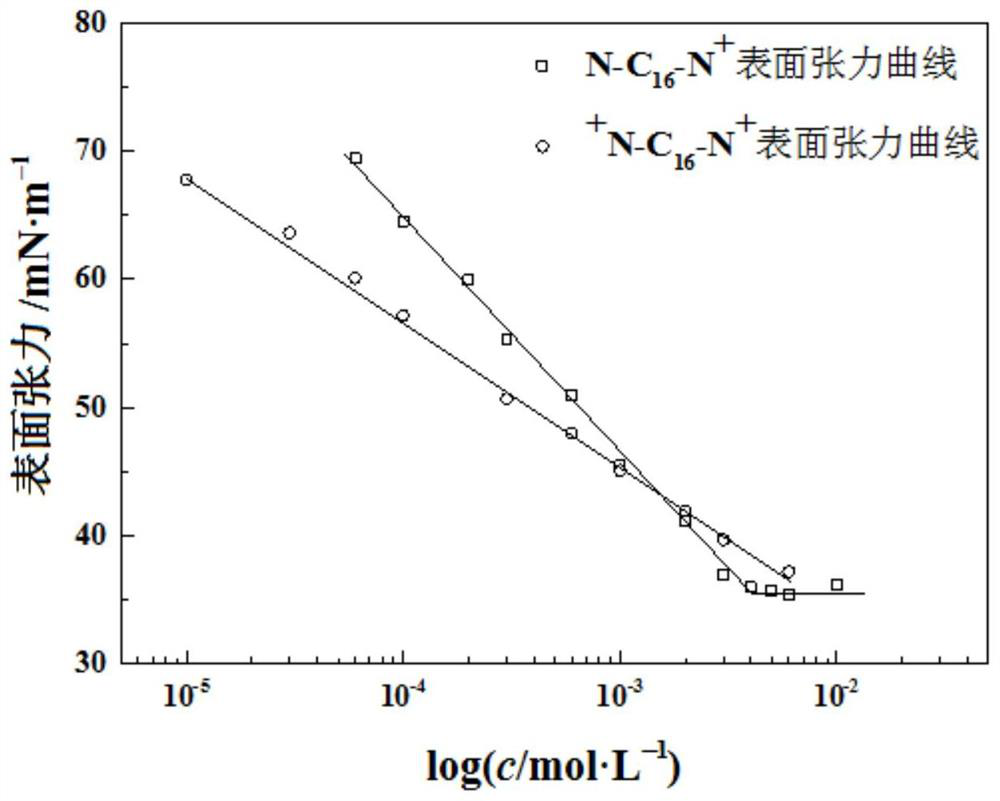

[0056] Example 3: N-16-N + Study on Stimulus-Response Properties of Surfactants

[0057] Prepare 5mM N-16-N + Surfactant aqueous solution (pH=10.75), take 7mL and add it to a 25mL vial, take 7mL n-decane, homogenize it with a high shear homogenizer for 2min, form a stable O / W emulsion and place it in a 25°C incubator , pH stimulation-response adjustment was performed after standing for 24 hours.

[0058] Adjust the pH value of the solution. When the pH value is around 3, the emulsion breaks and separates the oil layer. One of the samples takes the upper oil layer and replaces it with fresh n-decane; when the pH value returns to the original value (pH 10.75) After that, homogeneously emulsify again to form a stable emulsion. Such as Figure 4 and 5 As shown, the micrograph of the decane-exchanged emulsion agrees with the micrograph of the un-exchanged emulsion; and by Figure 6 In the NMR analysis, due to the N-C n -N + The solubility in n-decane is poor, and we use tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com