Composite catalyst for directly preparing high-value aromatic hydrocarbons from carbon dioxide as well as preparation method and application

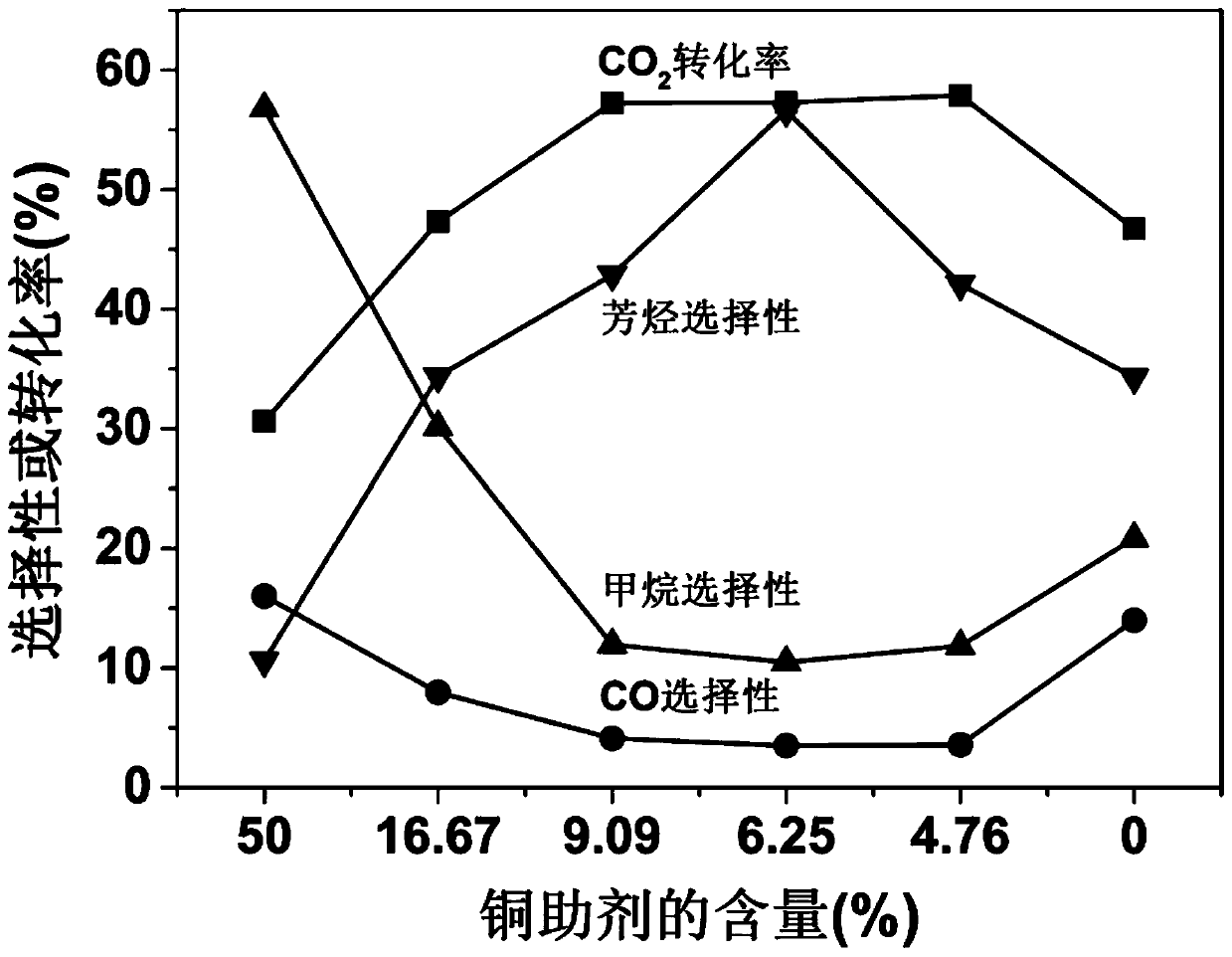

A composite catalyst, carbon dioxide technology, used in catalyst activation/preparation, hydrocarbon production from carbon oxides, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high selectivity of by-product carbon monoxide and high conversion rate of carbon dioxide , low carbon dioxide conversion rate, etc., to achieve good industrial application prospects, improve conversion rate, and reduce the effect of greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

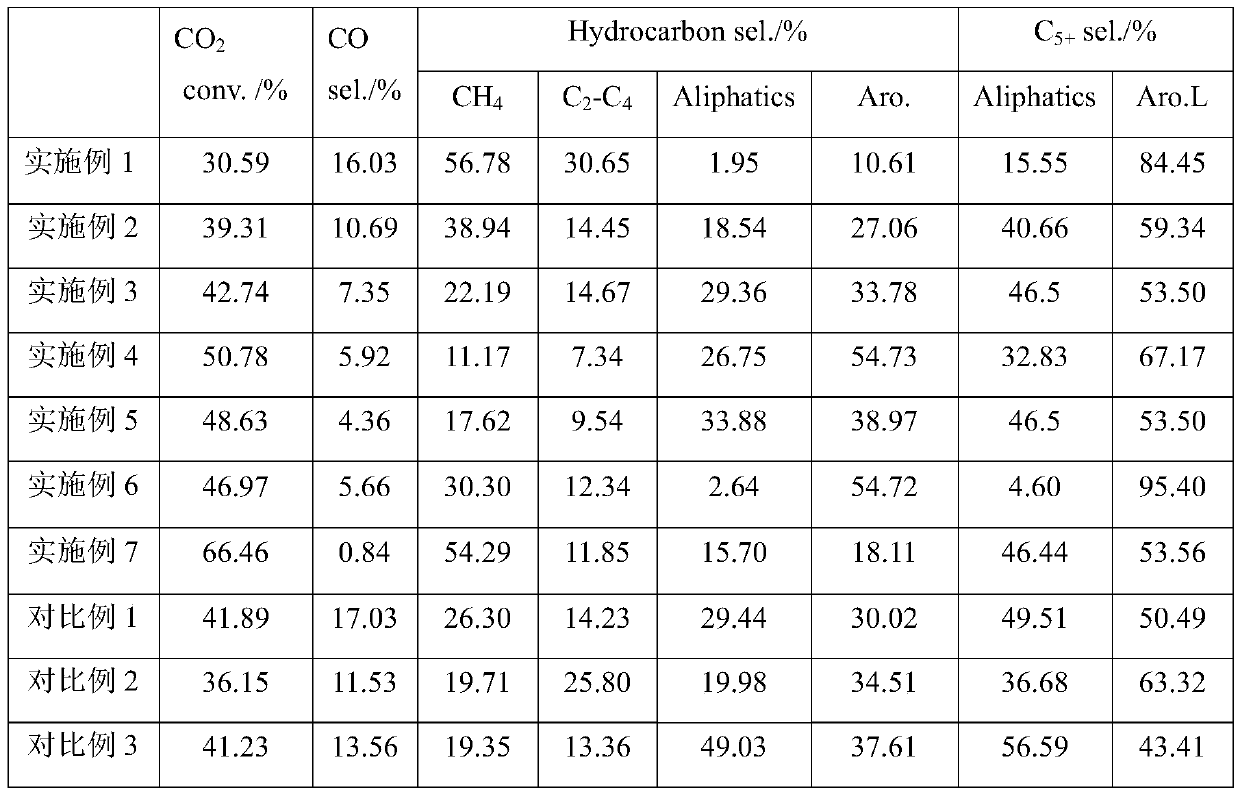

Embodiment 1

[0055] The first step, the preparation method of iron-copper metal oxide comprises the following steps:

[0056] Dissolve 30.3g of ferric nitrate nonahydrate and 18.12g of copper nitrate trihydrate in 150ml of deionized water to prepare a precursor solution, and stir and heat it in a constant temperature water bath to completely dissolve it. Weigh sodium hydroxide and dissolve it in water to prepare a precipitant with a concentration of 1mol / L. Under constant temperature conditions at a temperature of 70°C, slowly add sodium hydroxide solution dropwise to the precursor solution (dropping at a rate of every two seconds) , and keep stirring, monitor the pH of the solution by a pH meter, stop adding the sodium hydroxide solution dropwise when the pH reaches 6.7-7.0, keep the temperature constant and keep stirring, and age the generated precipitate for 30 minutes.

[0057] The obtained precipitate was separated by suction filtration, and the obtained filter cake was washed with 80...

Embodiment 2

[0073] The first step, the preparation method of iron-copper metal oxide comprises the following steps:

[0074] Dissolve 30.3g of ferric nitrate nonahydrate and 3.624g of copper nitrate trihydrate in 150ml of deionized water to prepare a precursor solution, and stir and heat it in a constant temperature water bath to completely dissolve it. Weigh sodium hydroxide and dissolve it in water to prepare a precipitant with a concentration of 1mol / L. Under constant temperature conditions at a temperature of 70°C, slowly add sodium hydroxide solution dropwise to the precursor solution (dropping at a rate of every two seconds) , and keep stirring, monitor the pH of the solution by a pH meter, stop adding the sodium hydroxide solution dropwise when the pH reaches 6.7-7.0, keep the temperature constant and keep stirring, and age the generated precipitate for 30 minutes.

[0075] The obtained precipitate was separated by suction filtration, and the obtained filter cake was washed with 80...

Embodiment 3

[0091] The first step, the preparation method of iron-copper metal oxide comprises the following steps:

[0092] Dissolve 30.3g of ferric nitrate nonahydrate and 1.812g of copper nitrate trihydrate in 150ml of deionized water to prepare a precursor solution, and stir and heat it in a constant temperature water bath to completely dissolve it. Weigh sodium hydroxide and dissolve it in water to prepare a precipitant with a concentration of 1mol / L. Under constant temperature conditions at a temperature of 70°C, slowly add sodium hydroxide solution dropwise to the precursor solution (dropping at a rate of every two seconds) , and keep stirring, monitor the pH of the solution by a pH meter, stop adding the sodium hydroxide solution dropwise when the pH reaches 6.7-7.0, keep the temperature constant and keep stirring, and age the generated precipitate for 30 minutes.

[0093] The obtained precipitate was separated by suction filtration, and the obtained filter cake was washed with 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com