Preparation method for flexible composite loaded with macro MOFs efficiently

A technology of composite materials and flexible substrates, which is applied in the direction of flat products, applications, coatings, etc., can solve the problems of difficult macro-production of MOFs/flexible composite materials, low loading of MOFs, poor environmental friendliness, etc., and achieve good industrial The effect of application prospect, low cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

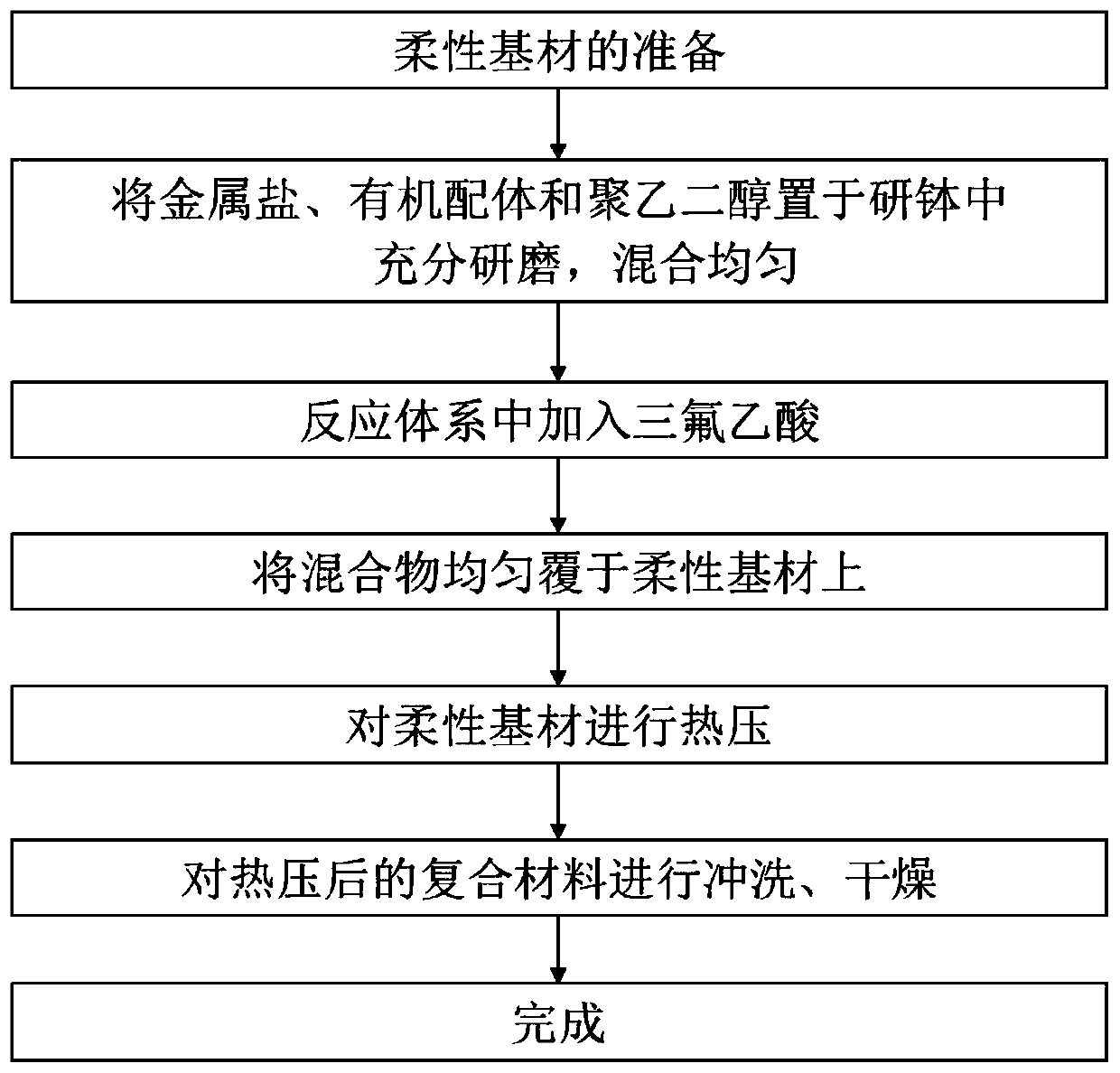

[0031] Preparation of MOF-808 / PP Composite by Hot Pressing with Trifluoroacetic Acid

[0032] 1) Prepare a commercially available polypropylene (PP) fabric, rinse it with NaOH aqueous solution to remove impurities and dust on the surface of the fabric, and then dry it at 50°C for use.

[0033] 2) Prepare the corresponding metal salt ZrOCl of MOF-808 2 ·8H 2 O (0.64g) and organic ligand H 3 BTC (0.44g) and polyethylene glycol (0.8mL, Mn=200) were thoroughly ground and mixed in an agate mortar. Add 0.2 mL of trifluoroacetic acid into the mortar, continue to grind and mix well. The mixture was uniformly coated on a PP film (20cm×20cm), wrapped with aluminum foil, and hot pressed using a hot press at a temperature of 200°C for 15 minutes. After the hot pressing, the MOF-808 / PP nanofiber composite membrane material was taken out from the aluminum foil, rinsed three times with 10 mL deionized water and 10 mL acetone, and dried at 80 °C for 4 h.

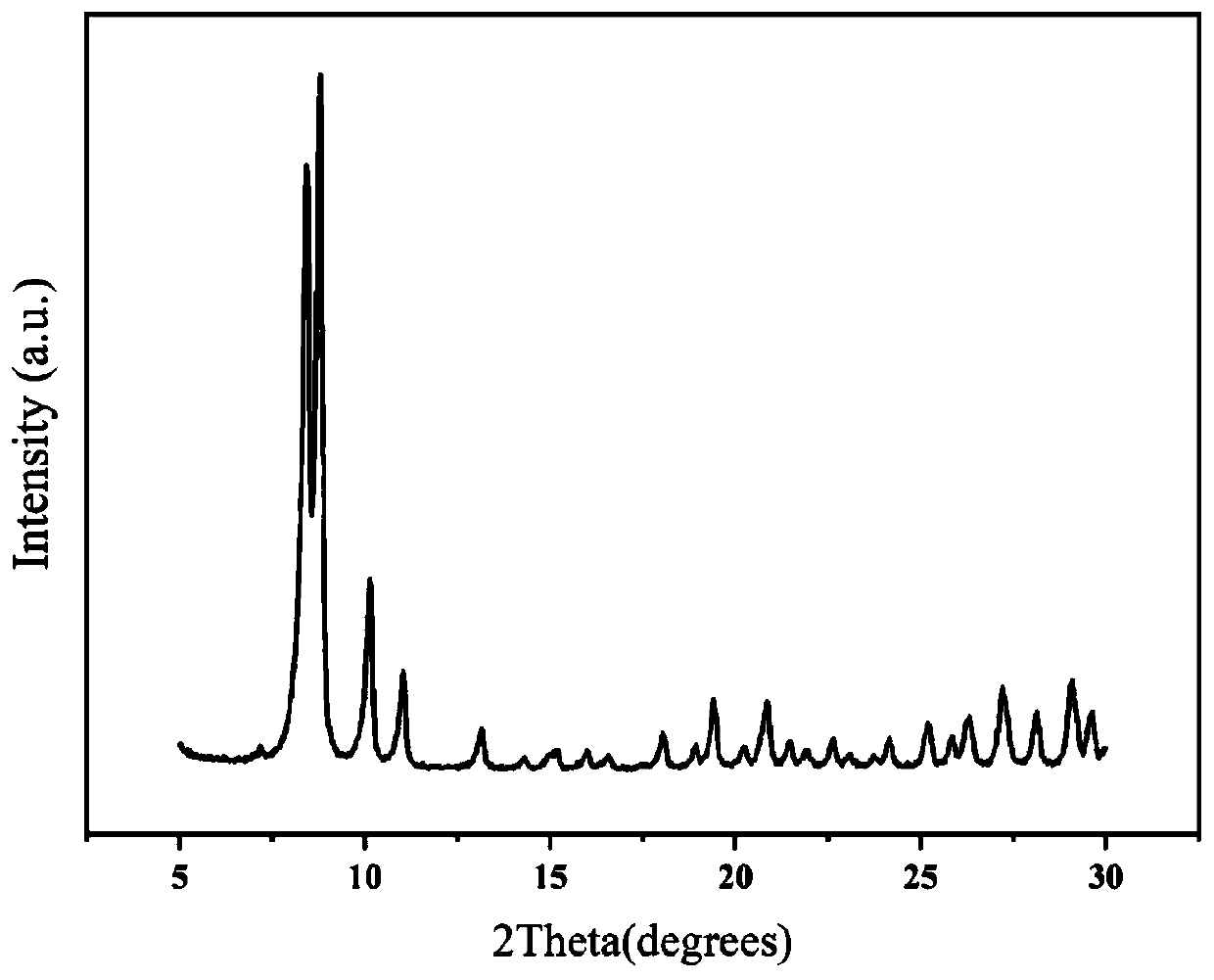

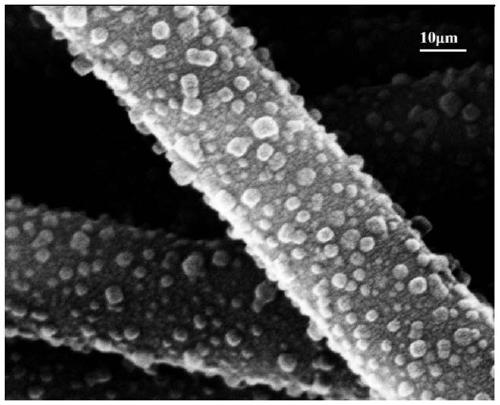

[0034] Such as figure 2 As sh...

Embodiment 2

[0037] 1) Weigh 2.0g PET and add it into a black cap bottle filled with 10mL DMF to make a spinning solution, and stir it magnetically for 8 hours to make it evenly mixed. The mixed spinning solution was placed in a syringe equipped with a 23# flat needle, at room temperature, the voltage was 18kV, and the flow rate was 1.5mL / h to prepare a nanofiber film and receive it with aluminum foil. The distance between the spinneret and the receiver is 20 cm. The prepared PET nanofiber film was dried in a vacuum oven at 50° C. for 6 hours, and then taken out for use. The diameter of the prepared PET film was about 300 nm to 500 nm.

[0038] 2) UiO-66-NH will be prepared 2 The corresponding metal salt ZrCl 4 (0.24g) and the organic ligand BDCA-NH 2 (0.20g) and polyethylene glycol (0.2g, Mn=4000) were placed in an agate mortar and thoroughly ground and mixed uniformly.

[0039] 3) Dilute trifluoroacetic acid: acetone according to the volume ratio of 1:10, put it into a spray gun, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com