Production method of clam active peptide

A production method and technology for active peptides, applied in the biological field, can solve the problems of complex reaction process, difficulty in applying a gel column separation process to large-scale production, and high cost of large-scale production, and achieve simple process, high production cost, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

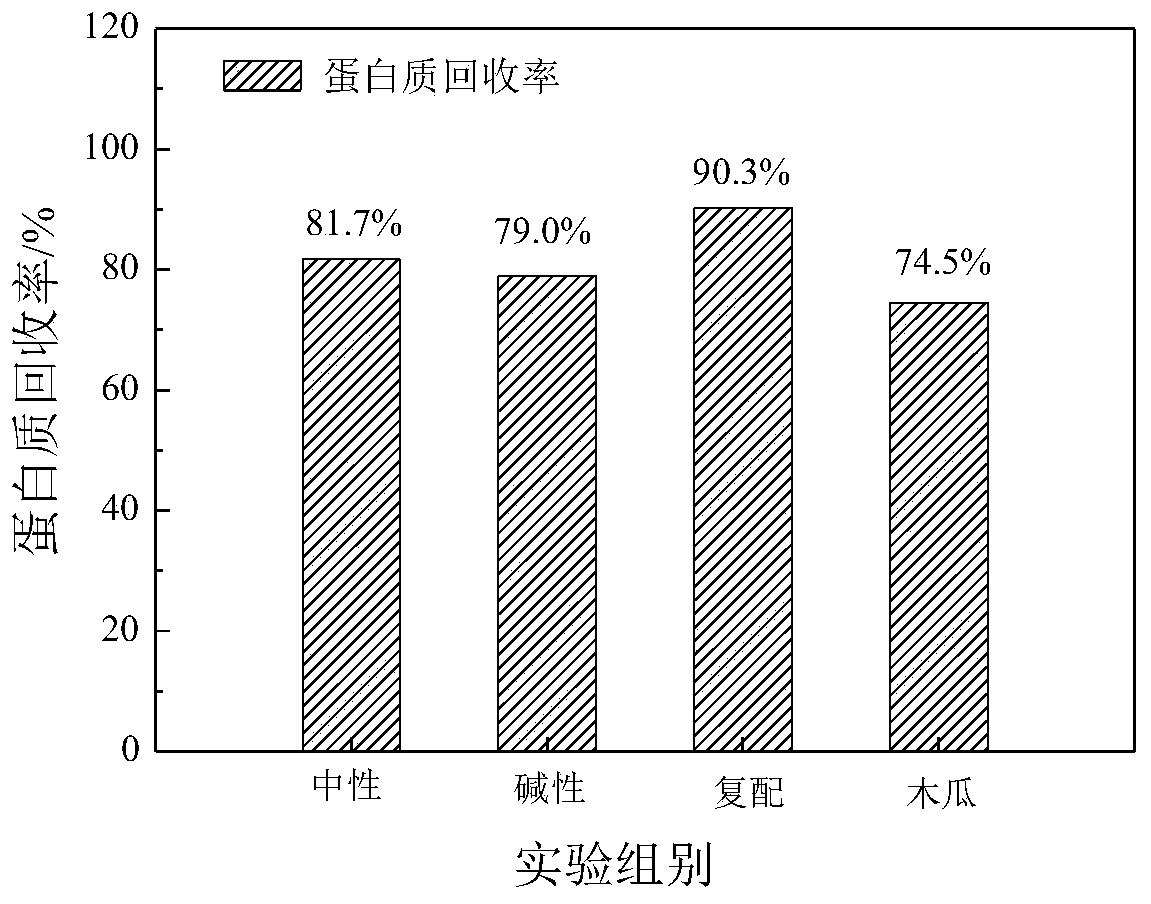

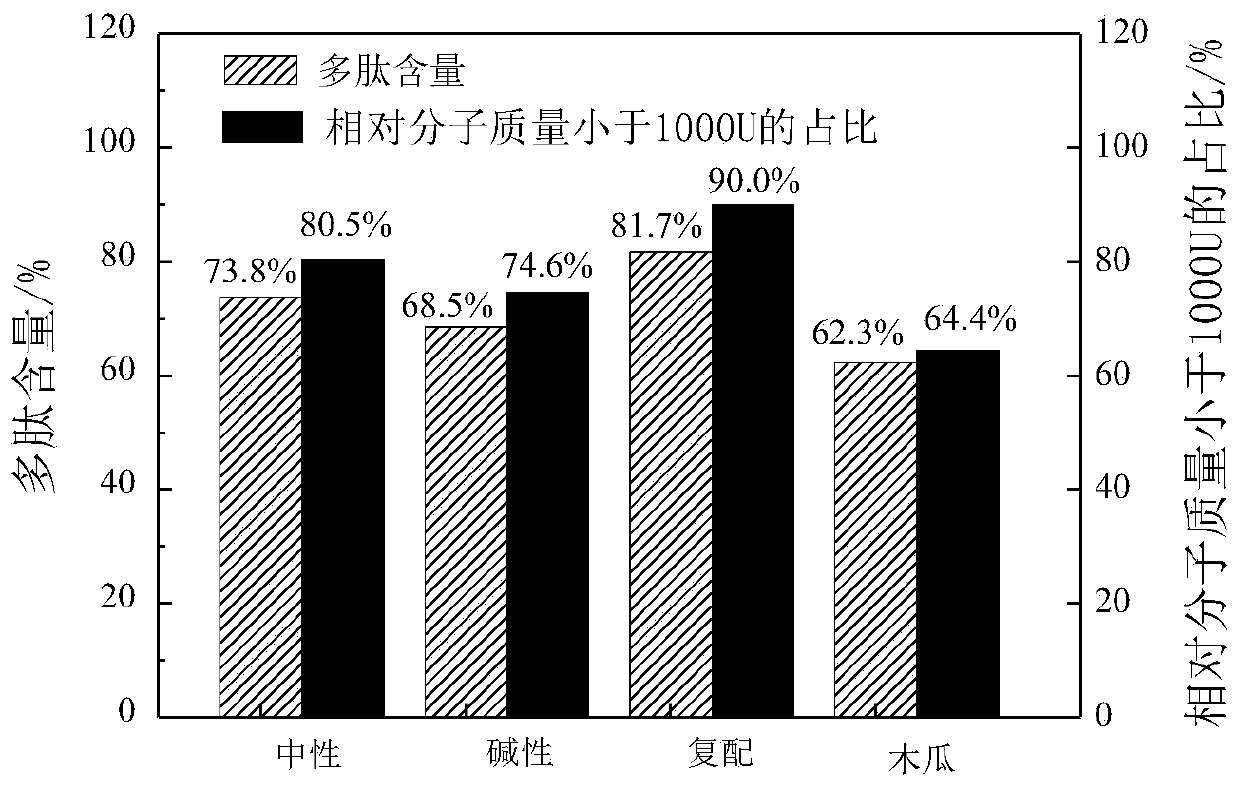

[0067] Embodiment 1: Comparison of enzymolysis effects of different proteases

[0068] Raw meat: Red Island clam meat.

[0069] Enzymes to be tested: neutral protease, alkaline protease, papain, compound protease.

[0070] Enzymolysis process flow: get frozen Hongdao clam meat, after thawing, add deionized water in a weight ratio of clam meat: water=1:1 and carry out homogenization; neutral protease, alkaline protease, papain, compound protease ( The formula is neutral protease:alkaline protease:flavor protease=2:1:1), the enzymolysis temperature is 50°C, the amount of enzyme added is 0.13% of the clam pulp, and the pH is the natural pH value; Inactivate the enzyme at 85°C for 10 minutes, centrifuge at 4000r / min for 30 minutes, and take the supernatant.

[0071] The detection result of table 2 enzymatic hydrolysis gained product

[0072]

[0073] It can be seen from the results in Table 2 that among the four proteolytic enzymes screened, the protein recovery rate, polype...

Embodiment 2

[0074] Embodiment 2: the industrialized production method of clam active peptide of the present invention

[0075] Raw meat: Red Island clam meat.

[0076] Enzyme to be tested: composite protease.

[0077]Enzymatic hydrolysis process: take the frozen Hongdao clam meat, after thawing, add deionized water to homogenize according to the weight ratio of clam meat: water = 1:1, add a certain amount of deionized water to the clam meat slurry, so that The weight ratio of final clam meat: water = 1:2; the enzymolysis temperature of the compound protease (the formula is neutral protease: alkaline protease: flavor protease = 2:1:1) is 50°C, and the amount of enzyme added is clam meat slurry 0.13% of pH, the pH is the natural pH value; heat preservation for 4 hours, inactivate the enzyme at 85°C for 10 minutes, centrifuge at 16000r / min, take the supernatant for membrane filtration, and spray-dry to obtain the clam active peptide.

Embodiment 3

[0078] Embodiment 3: the industrialized production method of clam active peptide of the present invention

[0079] Raw meat: Red Island clam meat.

[0080] Enzyme to be tested: composite protease.

[0081] Enzymatic hydrolysis process: take the frozen Hongdao clam meat, after thawing, add deionized water to homogenize according to the weight ratio of clam meat: water = 1:1, add a certain amount of deionized water to the clam meat slurry, so that The weight ratio of final clam meat: water = 1:3; the enzymolysis temperature of the compound protease (the formula is neutral protease: alkaline protease: flavor protease = 2:1:1) is 50°C, and the amount of enzyme added is clam meat slurry 0.13% of pH, the pH is the natural pH value; heat preservation for 4 hours, inactivate the enzyme at 85°C for 10 minutes, centrifuge at 16000r / min, take the supernatant for membrane filtration, and spray-dry to obtain the clam active peptide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com