Composite fermentation microbial inoculant and application of composite fermentation microbial inoculant in preparation of citrus pulp bio-organic fertilizer

A technology of compound fermentation bacteria agent and bio-organic fertilizer, applied in the field of agricultural soil fertilizer, can solve the problems of unsatisfactory effect of citrus pulp peel residue, unfavorable large-scale popularization and application, long fertilizer production cycle, etc., so as to avoid soil nutrient imbalance and promote Effects of soil regeneration and sustainable utilization, avoidance of calcification and alkalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

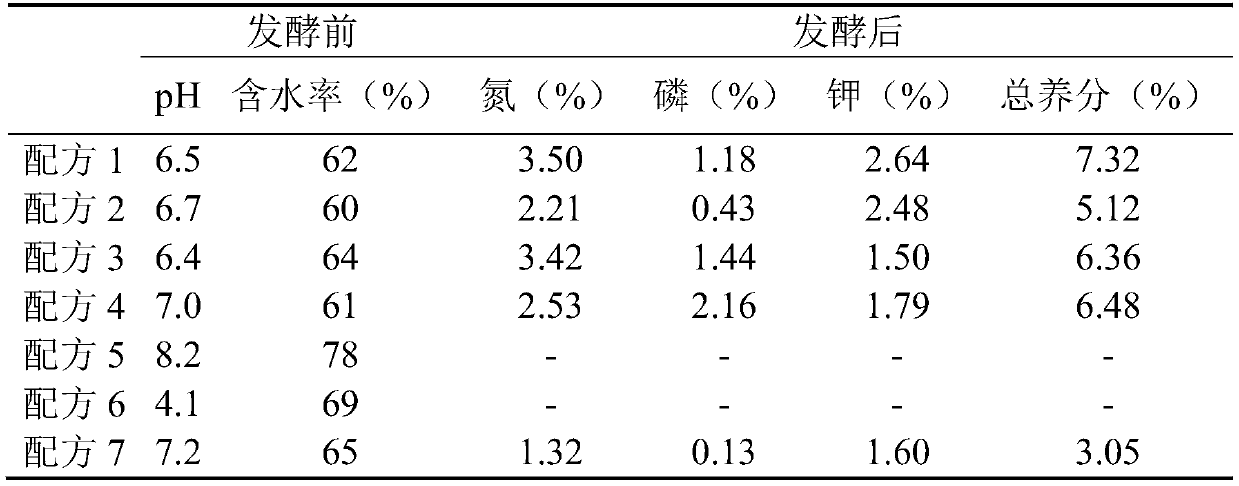

[0067] Example 1: Compounding citrus pulp and industrial and agricultural waste to prepare bio-organic fertilizer

[0068] Prepare ingredients as follows:

[0069] Formula 1: 98 parts by mass of citrus pulp, 20 parts by mass of peanut bran, 20 parts by mass of bean dregs, 20 parts by mass of beef slices, 20 parts by mass of herbal tea dregs, 18 parts by mass of wood bran, 0.4 parts by mass of urea and 4 parts by mass of molasses.

[0070] Formula 2: 98 parts by mass of citrus pulp, 20 parts by mass of bean dregs, 32 parts by mass of beef hide slices, 44 parts by mass of wood bran, 0.4 parts by mass of urea and 4 parts by mass of molasses.

[0071] Formula 3: 90 parts by mass of citrus pulp, 10 parts by mass of peanut bran, 10 parts by mass of wheat bran, 20 parts by mass of mushroom dregs, 32 parts by mass of cowhide meat slices, 8 parts by mass of herbal tea residue, 0.4 parts by mass of urea and 4 parts by mass of molasses.

[0072] Formula 4: 90 parts by mass of citrus pulp,...

Embodiment 2

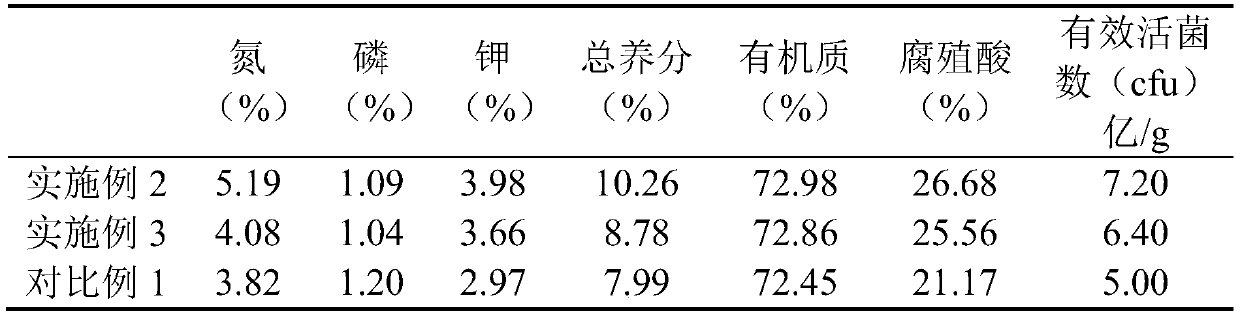

[0088] Example 2: Enzymolysis + compound bacteria two-step fermentation method to prepare bio-organic fertilizer

[0089] Raw materials are prepared according to the following mass ratio: citrus pulp: peanut bran: bean dregs: cowhide meat slices: herbal tea residue: wood bran: urea: molasses: cellulase: neutral protease: fertilizer fermentation bacteria (10 7 CFU / g): Trichoderma viride (10 7 CFU / g): Bacillus subtilis (10 6 CFU / g): Enterococcus faecalis (10 6 CFU / g)=98:20:20:20:20:18:0.4:4:0.02:0.02:1:0.2:0.02:0.002;

[0090] Prepare bio-organic fertilizer according to the following steps:

[0091] (1) Crush the citrus pulp and set aside; crush the herbal tea residue to a particle size of 1-1.5 cm; cut the beef hide slices to a particle size of 2-5 cm and set aside.

[0092] (2) Mix citrus pulp, peanut bran, bean dregs, cowhide meat grains, herbal tea dregs, wood bran, urea and molasses evenly, then add cellulase and neutral protease and mix evenly to obtain a total of 1000...

Embodiment 3

[0095] Embodiment 3 enzymatic hydrolysis and compound bacteria one-step fermentation method prepares bio-organic fertilizer

[0096] Raw materials are prepared according to the following mass ratio: citrus pulp: peanut bran: bean dregs: cowhide meat slices: herbal tea residue: wood bran: urea: molasses: cellulase: neutral protease: fertilizer fermentation bacteria (10 7 CFU / g): Trichoderma viride (10 7 CFU / g): Bacillus subtilis (10 6 CFU / g): Enterococcus faecalis (10 6 CFU / g)=98:20:20:20:20:18:0.4:4:0.02:0.02:1:0.2:0.02:0.002;

[0097] Prepare bio-organic fertilizer according to the following steps:

[0098] (1) Crush the citrus pulp and set aside; crush the herbal tea residue to a particle size of 1-1.5 cm; cut the beef hide slices to a particle size of 2-5 cm and set aside.

[0099] (2) Mix citrus pulp, peanut bran, bean dregs, cowhide meat grains, herbal tea dregs, wood bran, urea and molasses, then add cellulase and neutral protease and mix uniformly to get 1000kg of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com