Wet-method flue gas denitration process regenerating potassium permanganate

A technology of potassium permanganate and flue gas, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of spray tower blockage, reduce the cost of chemicals, etc., to increase the consumption of urea, improve the utilization rate, The effect of avoiding decomposition side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

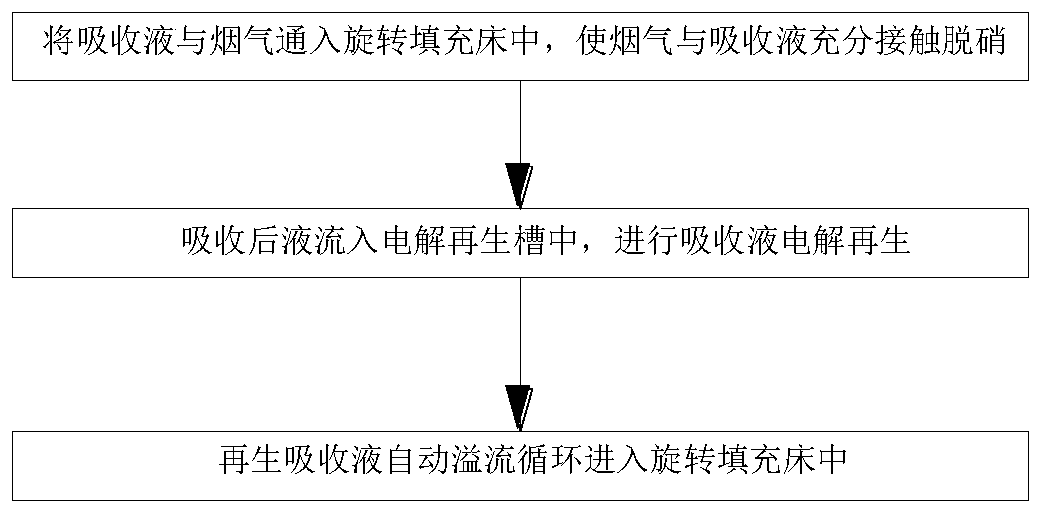

[0018] A wet flue gas denitrification process of regenerated potassium permanganate, such as figure 1 shown, including the following steps:

[0019] S1. Pass the absorption liquid and the flue gas into the rotating packed bed, make the flue gas fully contact with the absorption liquid, and at least part of the NO in the flue gas is oxidized into easily absorbed NO 2 , and further reduction yields N 2 , to achieve efficient removal of nitrogen oxides; the absorption liquid includes potassium permanganate, sodium hydroxide and urea;

[0020] The reaction of step S1 is shown in the following formula:

[0021] KMnO 4 +NOx→K 2 MnO 4 +MnO 2 +NO 2 (1)

[0022] NO 2 +CH 4 N 2 O→H 2 O+N 2 +CO 2 (2)

[0023] S2. Flow the absorbed liquid obtained after step S1 into the electrolytic regeneration tank for electrolytic regeneration of the absorption liquid; in the electrolytic regeneration tank, the current density is 10-60A / m 2 , the temperature of the electrolyte is 50-8...

Embodiment 2

[0029] Pass the absorption liquid and flue gas into the rotating packed bed, make the flue gas fully contact with the absorption liquid, and at least part of the NO in the flue gas is oxidized into easily absorbed NO 2 , further reduction produces N 2 , to achieve efficient removal of nitrogen oxides. The absorption liquid includes potassium permanganate, sodium hydroxide and urea. Rotating packed bed RPB speed is 1000r min -1 , the gas-liquid ratio is 150m 3 / L. The parameters of flue gas are: NOx concentration 200ppm, temperature 20°C. The concentration of potassium permanganate in the absorption liquid is 50g / L, the concentration of sodium hydroxide is 100g / L, and the mass concentration of urea is 15g / L. The denitrification efficiency reaches 84%.

[0030] Transfer the absorbed solution after the denitrification reaction to the electrolytic regeneration tank, where the electrolyte temperature is 65°C and the anode current density is 45A / m 2 Potassium permanganate can...

Embodiment 3

[0032] Pass the absorption liquid and flue gas into the rotating packed bed, make the flue gas fully contact with the absorption liquid, and at least part of the NO in the flue gas is oxidized into easily absorbed NO 2 , further reduction produces N 2 , to achieve high-efficiency removal of nitrogen oxides; the absorption liquid includes potassium permanganate, sodium hydroxide and urea. In this example, the rotational speed of the rotating packed bed RPB is 500r·min -1 , the gas-liquid ratio is 50m 3 / L. The flue gas parameters are: NO concentration 2000ppm, temperature 50°C. The concentration of potassium permanganate in the absorption liquid is 80g / L, the concentration of sodium hydroxide is 20g / L, and the mass concentration of urea is 30g / L. The denitrification efficiency reaches 88%.

[0033] Transfer the absorption solution after the denitrification reaction to the electrolytic regeneration tank. The temperature of the electrolyte is 50°C and the anode current densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com