Composite micron material, skin filling agent as well as preparation methods and application of composite micron material and skin filling agent

A technology of dermal fillers and composite microspheres, applied in pharmaceutical formulations, pharmaceutical sciences, prostheses, etc., can solve the problems of short validity period, particle adhesion, poor stability of mixed gel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 1) Preparation of polylysine-polylactic acid block copolymer microspheres

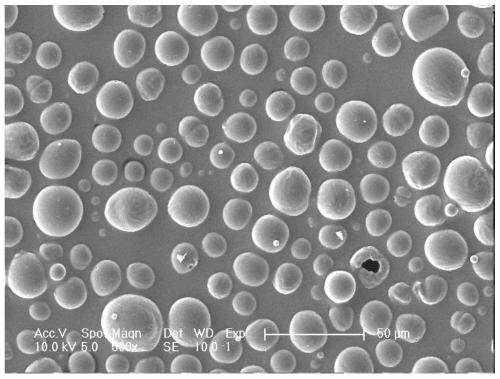

[0084] Dissolve 18 grams of polylysine-polylactic acid block copolymer in 270 milliliters of chloroform, add 3600 milliliters of mass concentration to 0.5% polyvinyl alcohol aqueous solution, and emulsify for 10 minutes at an emulsifier speed of 3000 rpm , a suspension of microspheres was obtained after removal of chloroform. The suspension was washed with water and dried to obtain 17.2 g of white microsphere powder with a yield of 95.6%. Its SEM picture see figure 1 , slightly elliptical microspheres can be seen from the figure, and the particle size of the microspheres is 2-32 μm. The contact angle of the test microsphere is 69° and the water absorption rate is 28.5%, which are listed in Table 1. Compared with the contact angle of 126° and the water absorption rate of 4.4% of the simple polylactic acid microspheres, its water absorption and water absorption rate are obviously improved .

...

Embodiment 2

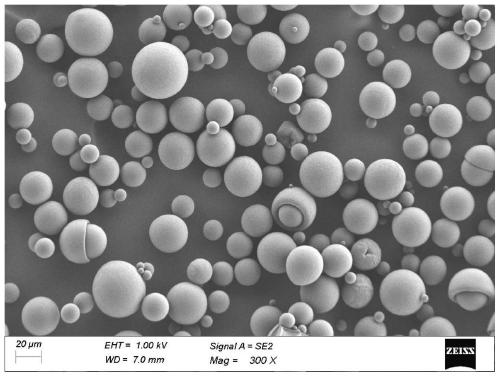

[0092] Dissolve 18g of polylysine amino acid-polycaprolactone block copolymer in 360mL of dichloromethane, add 2700mL of mass concentration to 2% gelatin aqueous solution, stir rapidly at 1400 rpm for 2 hours, remove the dichloromethane to obtain Aqueous suspension of microspheres. The aqueous suspension was washed with water and dried to obtain 16.5 g of white powder with a yield of 91.7%. Its SEM picture see figure 2 , it can be seen from the figure that the microspheres with regular shape core-shell structure, the particle size is 2-52μm, the contact angle is 86° and the water absorption rate is 14.3%, which are listed in Table 1. Compared with pure polycaprolactone microsphere Compared with the contact angle of 124° and the water absorption rate of 4.6%, the water absorption and water absorption rate are significantly improved.

[0093] The preparation method of polylysine-polycaprolactone block copolymer is: with reference to the method of patent CN 102827367B, take by...

Embodiment 3

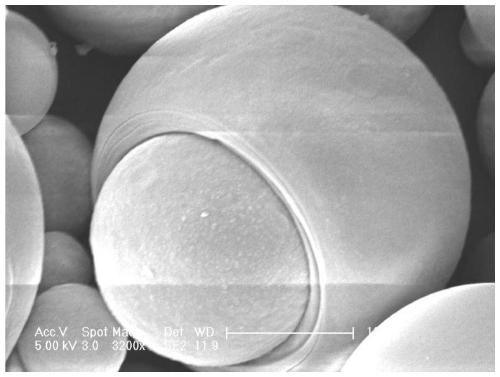

[0098] To the mass concentration of 1000mL is 1% gelatin aqueous solution, add the 100mL chloroform solution of 5g poly-benzyl glutamate and polylactic acid mixture, wherein the mol ratio of poly-lactic acid and poly-benzyl glutamate is 8:1, in Emulsify for 15 minutes at an emulsification speed of 2500 rpm, and remove the chloroform to obtain an aqueous suspension of microspheres. The aqueous suspension was washed with water and dried to obtain 4.75 g of white powder with a yield of 95%. Its SEM picture see image 3 , It can be seen from the figure that the composite microspheres of polybenzyl glutamate and polylactic acid with a core-shell structure have a particle size of 5-45 μm. Its contact angle of 82° and water absorption rate of 15.2% are tested, which are listed in Table 1. Compared with the contact angle of 126° and water absorption rate of 4.4% of pure polylactic acid microspheres, its water absorption and water absorption rate are significantly improved.

[0099] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com