Flame-retardant high-damping rubber composition, preparation method and application thereof

A rubber composition and high damping technology are applied in the field of flame retardant and high damping rubber compositions and their preparation, and can solve the problems of less materials involving aging resistance, poor weather resistance, decomposition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

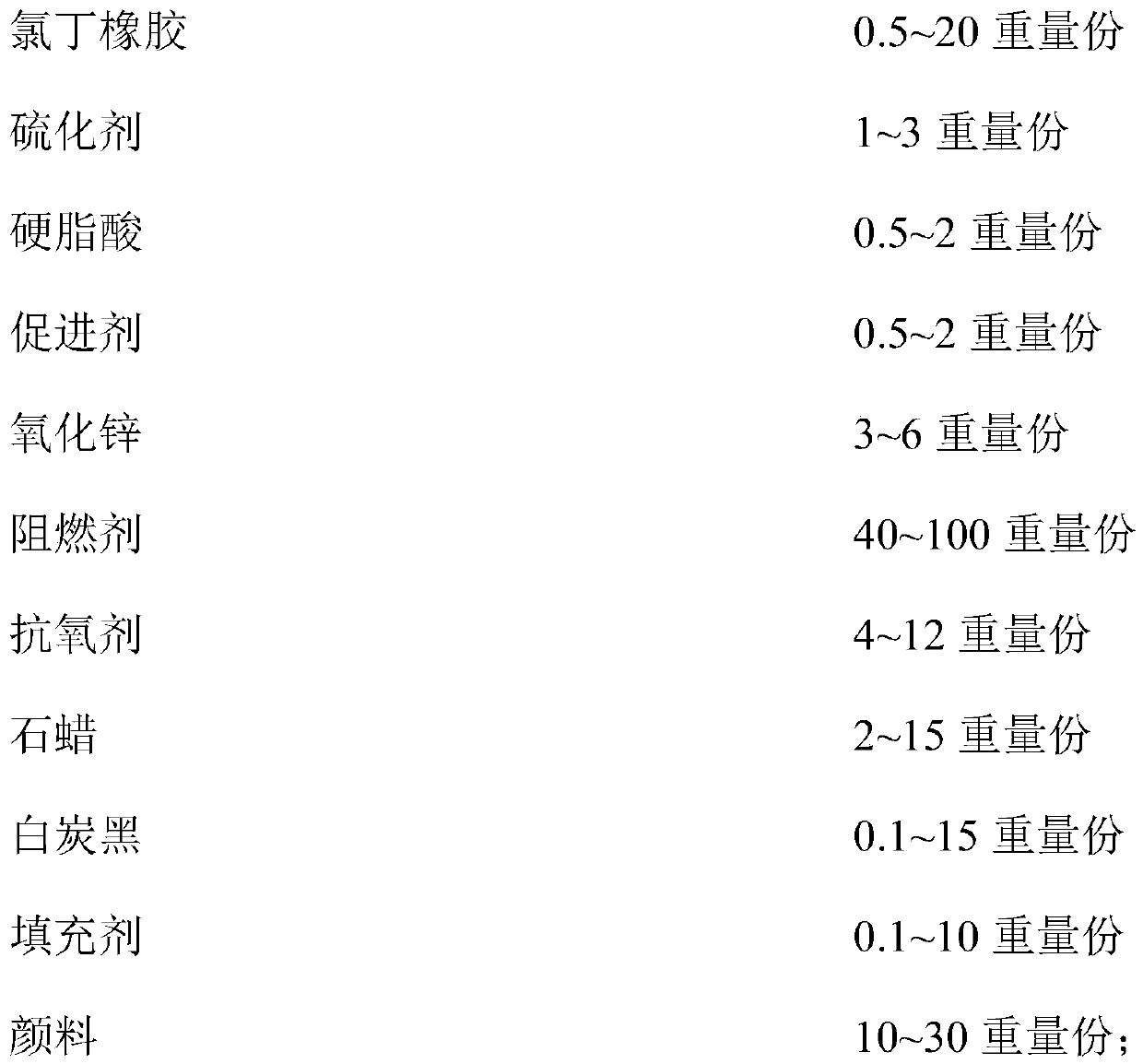

[0086] This embodiment provides a rubber composition with flame retardancy and high damping, the components are as follows:

[0087]

[0088]

[0089] Among them, the vulcanizing agent is sulfur; the flame retardant is a mixture of decabromodiphenylethane / environmentally friendly antimony trioxide, melamine polyphosphate, aluminum hydroxide and hydrotalcite in a mass ratio of 35:25:10:1 Composite flame retardant, the mass ratio of decabromodiphenylethane and environmentally friendly antimony trioxide is 3:2; the antioxidant is o-hydroxybenzotriazole compounds, benzylidene malonate compounds and A composite antioxidant made by mixing tetramethylpiperidine hindered amines at a mass ratio of 5:2:3; the filler is heavy calcium; the pigment is titanium dioxide, blue powder and red powder mixed at a mass ratio of 10:0.1:0.01 become.

[0090] Described rubber composition is white, and preparation method is as follows:

[0091] (1) Add bromobutyl rubber, chloroprene rubber, st...

Embodiment 2

[0095] This embodiment provides a rubber composition with flame retardancy and high damping, the components are as follows:

[0096]

[0097] Among them, the vulcanizing agent is dicumyl peroxide DCP; the flame retardant is decabromodiphenylethane / environmentally friendly antimony trioxide, melamine polyphosphate, aluminum hydroxide and hydrotalcite in a mass ratio of 40:35:5 :2 is a composite flame retardant mixed with decabromodiphenylethane and environmentally friendly antimony trioxide in a mass ratio of 3:2; A compound antioxidant made by mixing diacid ester compounds and tetramethylpiperidine hindered amines in a mass ratio of 6:3:3; the filler is heavy calcium; the pigments are titanium dioxide, blue powder and red powder in a mass ratio of 15 :0.2:0.01 mixed.

[0098] Described rubber composition is white, and preparation method is as follows:

[0099] (1) Add bromobutyl rubber, stearic acid, antioxidant, accelerator TMTD, zinc oxide, filler and flame retardant in...

Embodiment 3

[0103] This embodiment provides a rubber composition with flame retardancy and high damping, the components are as follows:

[0104]

[0105] Among them, the vulcanizing agent is sulfur; the flame retardant is a mixture of decabromodiphenylethane / environmentally friendly antimony trioxide, melamine polyphosphate, aluminum hydroxide and hydrotalcite in a mass ratio of 40:35:10:1.5 Composite flame retardant, the mass ratio of decabromodiphenylethane and environmentally friendly antimony trioxide is 3:2; the antioxidant is o-hydroxybenzotriazole compounds, benzylidene malonate compounds and A composite antioxidant made of tetramethylpiperidine hindered amines mixed at a mass ratio of 4:4:4; the filler is heavy calcium; the pigment is titanium dioxide, blue powder and red powder mixed at a mass ratio of 12:0.1:0.01 become.

[0106] Described rubber composition is white, and preparation method is as follows:

[0107] (1) Add bromobutyl rubber, chloroprene rubber, stearic acid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com