Microstructure optical fiber capable of simultaneously transmitting optical information and optical energy

A technology of micro-structure optical fiber and optical information, which is applied in the field of laser energy transmission and optical fiber communication, and achieves the effects of low price, low mode dispersion and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

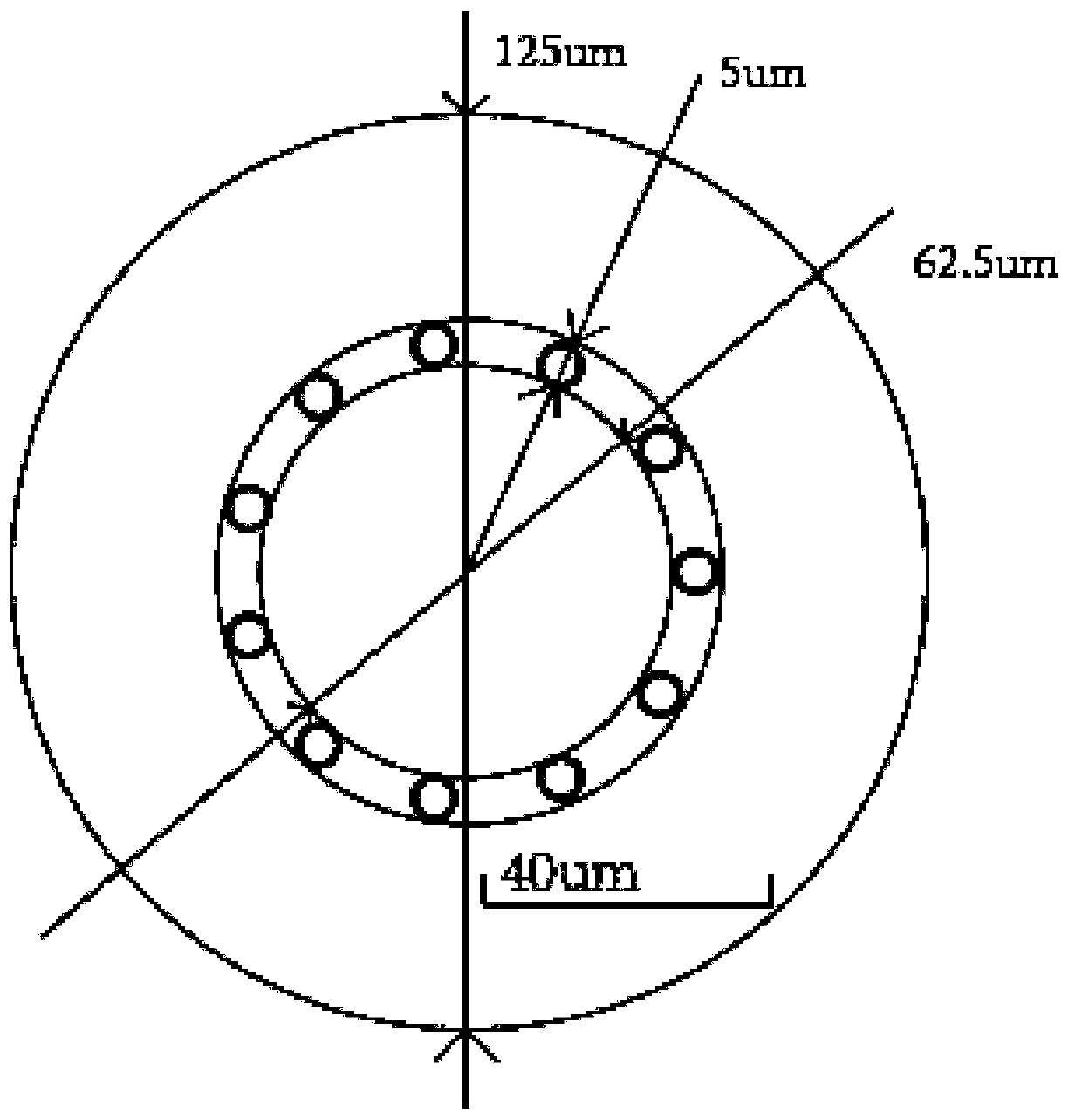

[0043] Such as figure 1 As shown, the present invention provides a microstructure optical fiber for the joint transmission of optical information and optical energy, and its structural design is completed by Comsol multi-physics simulation software. figure 1 The end view of the optical fiber is designed. The core of the optical fiber is a solid core, and the cladding is surrounded by periodically arranged air holes. The air holes are filled with air, which are air holes, and the air holes are embedded with the perfect matching layer. The core diameter is 62.5 μm, the cladding diameter is 125 μm, the cladding air hole diameter is 5 μm, the cladding air hole wall thickness is 0.5 μm, and the perfect matching layer size is 20 μm wide (not shown in the figure).

[0044] Specifically, the designed signal-energy co-transmission microstructure fiber is made of all-silicon material, and the core refractive index is shown in Table 1 below. The concept of signal-energy co-transmission s...

Embodiment 2

[0051] The invention provides a method for preparing a microstructured optical fiber that transmits optical information and optical energy together, comprising the following steps:

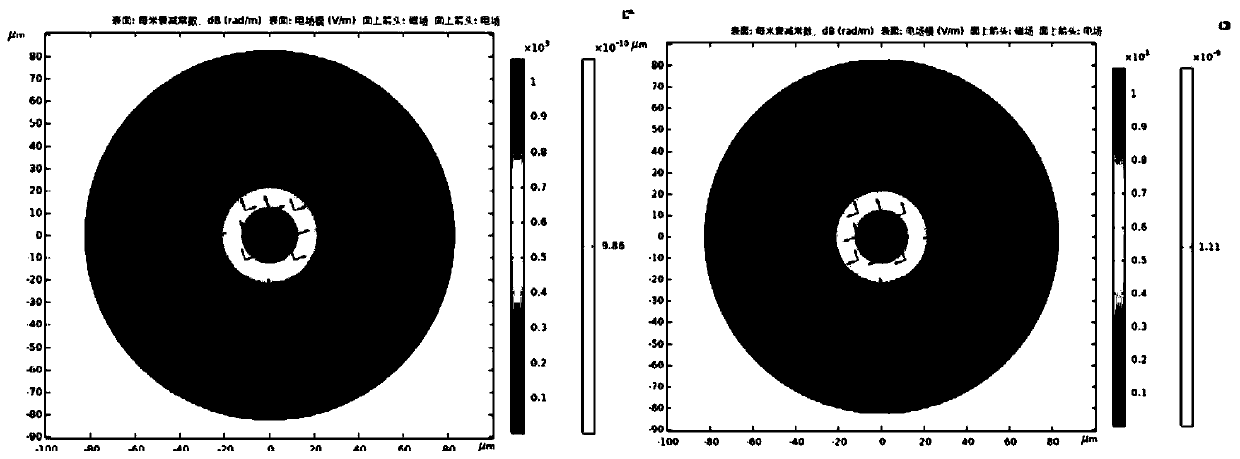

[0052] Step A: Import the designed signal-energy co-transmission microstructure fiber into Comsol software for physical field simulation analysis of its loss and mode field distribution;

[0053]Step B: Enlarge the optical fiber structure designed in step A according to the proportion of the cross-sectional view, select the appropriate sleeve and capillary, and arrange the optical fiber preform;

[0054] Step C: welding one end of the optical fiber preform obtained in step B to a sleeve with a slightly larger inner diameter and a similar outer diameter;

[0055] Step D: putting the optical fiber preform obtained in step C into a drawing tower as a whole for optical fiber drawing;

[0056] Step E: Leave the end of the drawn optical fiber long enough to wind the coil;

[0057] Specifically, in ste...

Embodiment 3

[0068] The present invention also provides a fusion splicing scheme for a large-core-diameter microstructure optical fiber that simultaneously transmits optical information and optical energy to be connected to an all-fiber signal energy co-transmission detection system, including the following steps:

[0069] Step A: Cut both ends of the signal-energy co-transmission microstructure fiber flat, use an optical fiber cutting machine, adjust appropriate cutting parameters, and control the number of cutting knives at 11-20;

[0070] Step B: splicing the two ends of the signal energy co-propagation microstructure fiber obtained in step A with the multimode pigtail matching the laser of the detection system used;

[0071] Step C: put the whole optical fiber obtained in step B into a loss measurement system to measure the splice loss.

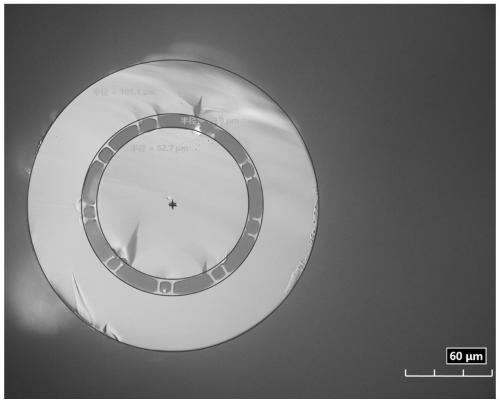

[0072] Such as Figure 4 As shown, specifically, the light cutting machine used in step A is a Fujikura CT105 fiber cutting machine, which is suitab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com