Method for treating high-concentration nickel-phosphorus-containing organic waste liquid through electrolytic oxidation

A technology of electrolytic oxidation and organic waste liquid, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, filtration treatment, etc., can solve the problems of low COD removal rate, high cost, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

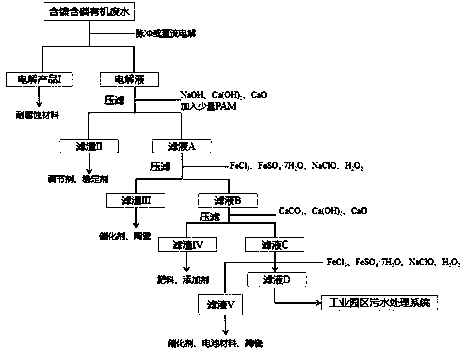

Image

Examples

Embodiment 1

[0020] (1) Accurately weigh 6 L of high-concentration nickel- and phosphorus-containing organic waste liquid with a metering device, apply a pulse electric field (pulse frequency 1000HZ, duty cycle 0.5), and a current density of 250 A / m 2 , after electrolysis for 24 h, electrolysis product Ⅰ (purity 86%) and electrolyte were obtained;

[0021] (2) Take 200 mL of the electrolyte solution obtained in step (1), add calcium oxide (15 g calcium oxide), adjust the pH to 14, stir and react for 4 h, and obtain leaching filter residue II and filtrate A after separation;

[0022] (3) Adjust the pH of the A filtrate obtained in step (2) to 4, add ferric chloride and ferrous sulfate heptahydrate (ferrous chloride 1.5 g, ferrous sulfate heptahydrate 1.5 g), and stir for 20 min;

[0023] (4) Add hydrogen peroxide and sodium hypochlorite (hydrogen peroxide 12 g, sodium hypochlorite 12 g) to the filtrate in step (3), add a small amount of PAM, stir and react for 4 hours, pour it into a solid-...

Embodiment 2

[0027] (1) Accurately weigh 6 L of high-concentration nickel- and phosphorus-containing organic waste liquid with a metering device, apply a pulse electric field (pulse frequency 1000HZ, duty cycle 0.5), and a current density of 300 A / m 2 , after electrolysis for 24 h, electrolysis product Ⅰ (purity 85%) and electrolyte were obtained;

[0028] (2) Take 200 mL of the electrolyte solution obtained in step (1), add calcium oxide (20 g calcium oxide), adjust the pH to 14, stir and react for 4 h, and obtain leaching filter residue II and filtrate A after separation;

[0029] (3) Adjust the pH of the A filtrate obtained in step (2) to 4, add ferric chloride and ferrous sulfate heptahydrate (2 g of ferrous chloride, 2 g of ferrous sulfate heptahydrate), and stir for 20 min;

[0030] (4) Add hydrogen peroxide and sodium hypochlorite (hydrogen peroxide 16 g, sodium hypochlorite 16 g) to the liquid in step (3), add a small amount of PAM, stir and react for 4 hours, pour into the solid-l...

Embodiment 3

[0034] (1) Accurately weigh 6 L of high-concentration nickel- and phosphorus-containing organic waste liquid with measuring equipment, apply a pulse electric field (pulse frequency 1000HZ, duty ratio 0.5), and a current density of 200 A / m 2 , after electrolysis for 24 h, electrolysis product Ⅰ (purity 84%) and electrolyte were obtained;

[0035] (2) Take 200 mL of the electrolyte solution obtained in step (1), add calcium oxide (30 g calcium oxide), adjust the pH to 14, stir and react for 4 hours, and obtain leaching filter residue II and solution A after separation;

[0036] (3) Adjust the pH of the A filtrate obtained in step (2) to 4, add ferric chloride and ferrous sulfate heptahydrate additives (1.5 g of ferrous chloride, 2 g of ferrous sulfate heptahydrate), and stir for 20 min;

[0037] (4) Add hydrogen peroxide and sodium hypochlorite (hydrogen peroxide 12 g, sodium hypochlorite 16 g) to the liquid in step (3), add a small amount of PAM, stir and react for 4 hours, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com