Adhesive for conductive cloth adhesive tape, conductive cloth adhesive tape and preparation method and application thereof

An adhesive and conductive cloth technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of poor flexibility and hard colloid, and achieve strong adhesion, moderate flexibility and adhesion strength. The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] An adhesive for conductive cloth tape, made of the following raw materials by weight: epoxy resin: 28 parts, silicone resin: 14 parts, flaky silver powder: 89 parts, white carbon black: 3.5 parts, curing agent: 25 parts parts, accelerator: 18 parts, microcrystalline wax: 10 parts, pine tar oil: 3.6 parts, sorbitol: 5 parts.

[0065] The epoxy resin includes bisphenol A type epoxy resin and acrylic epoxy resin, the average relative molecular weight of the bisphenol A type epoxy resin is 300-700, the polymerization degree n<2, and the softening point is lower than 50°C. The silicone resin is vinyl terminated T-type phenyl polysiloxane. Accelerators include N,N-dimethylaniline and 2,4,6,-tris(dimethylaminomethyl)phenol.

[0066] Silica is precipitated silica. The concentration of sorbitol is more than 60%.

[0067] The curing agent is a mixture of curing agent 1 for epoxy resin and curing agent 2 for silicone resin in a weight ratio of 1.2:0.5. Curing agent 1 contains t...

Embodiment 2-6

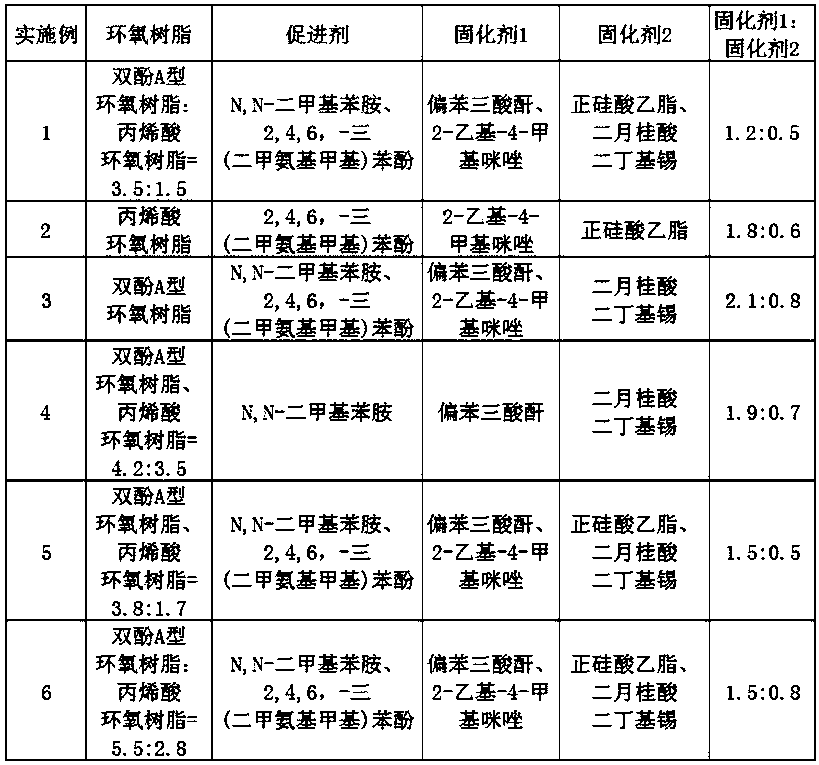

[0073] The adhesives in Examples 2-6 are different from the adhesives in Example 1 in the amount of raw materials, see Table 1 for details;

[0074] The adhesive of embodiment 2-6 is different from the epoxy resin, accelerator, curing agent 1 and curing agent 2 in the raw material of the adhesive in embodiment 1, and the weight of curing agent 1 and curing agent 2 The ratio is different, see Table 2 for details;

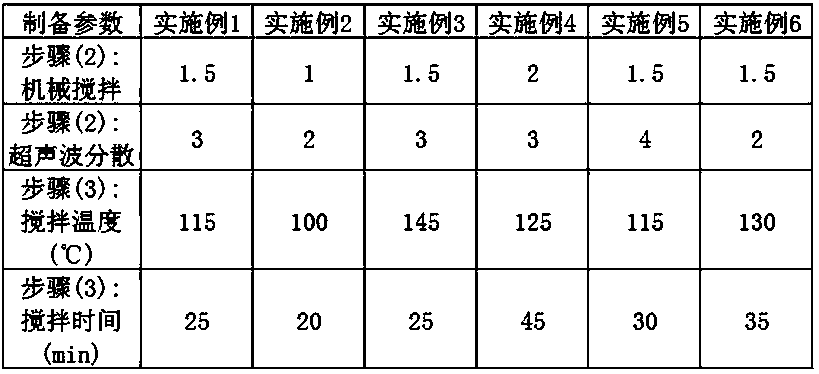

[0075] In the preparation method of the adhesive in embodiment 2-6 and the adhesive in embodiment 1, the stirring time in step (2), the ultrasonic dispersion time are different, and the stirring temperature and stirring time in step (3) are different , see Table 3 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com