Preparation method of pH and temperature dual stimuli-responsive food fresh-keeping nano cellulose hydrogel film

A nano-cellulose and stimuli-responsive technology, which is applied in the direction of protecting fruits/vegetables with a coating protective layer, can solve the problems of short timeliness of preservatives, serious residues, and no fruit responsiveness, etc., to extend the storage period, The effect of energy consumption reduction and full and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 100g of wheat straw with a water content of 8% was pulverized with a pulverizer, treated with a mixed solution of 5wt% sodium hydroxide and 1wt% sodium sulfite at 120°C for 3h, then boiled in 15wt% hydrogen peroxide solution for 5h, and then distilled water Washing and drying to obtain wheat straw cellulose. Weigh 0.75g of TEMPO (2,2,6,6-tetramethylpiperidine oxide), 5g of sodium bromide in a 250mL three-necked flask containing 100ml of deionized water, stir and dissolve, and add 50g of wheat straw cellulose powder. At 25°C, adjust the pH value of the sodium hypochlorite (available chlorine 12%, 5mmol / g) solution to about 10 by 0.1mol / L HCl, and slowly add the sodium hypochlorite solution dropwise to the flask, while adjusting the pH of the reaction system with 0.5mol / L NaOH Keep the pH around 10, and after the sodium hypochlorite solution is dripped within one hour, continue the reaction until the pH does not drop. Then use a high-speed shear homogenizer (AD200L-H) at...

Embodiment 2

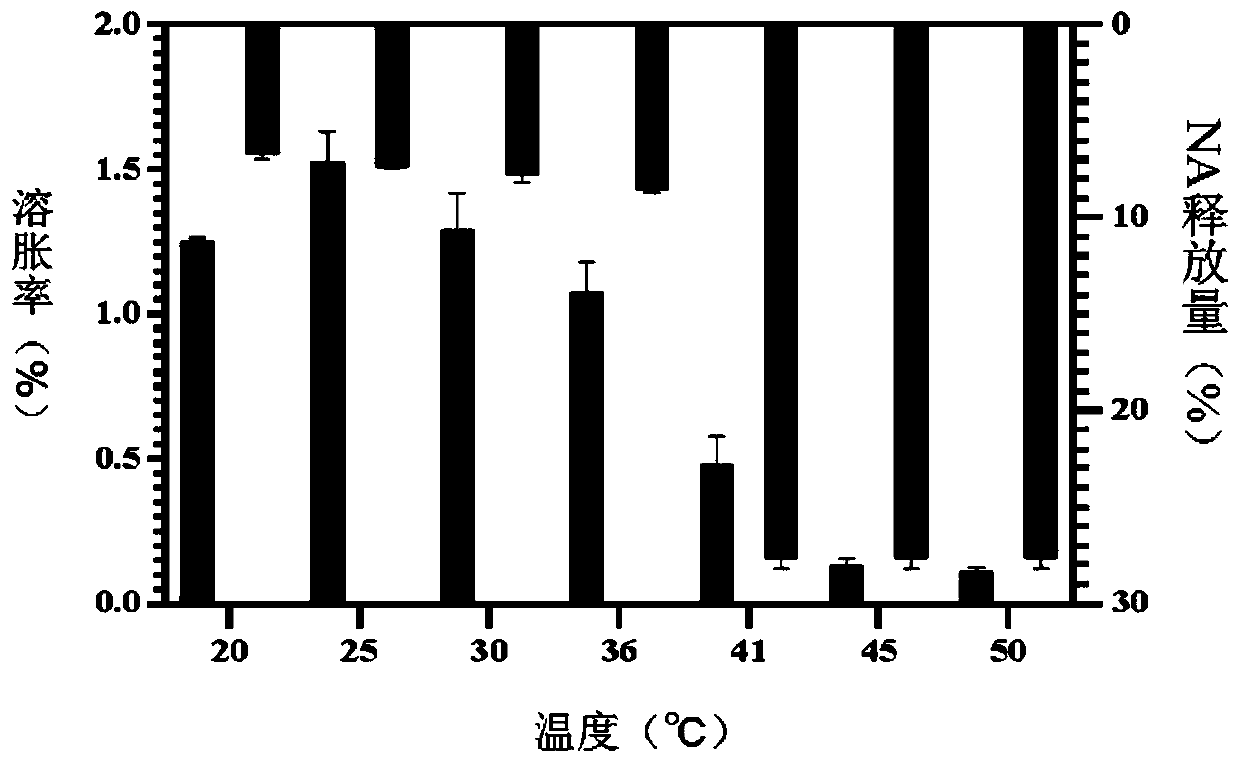

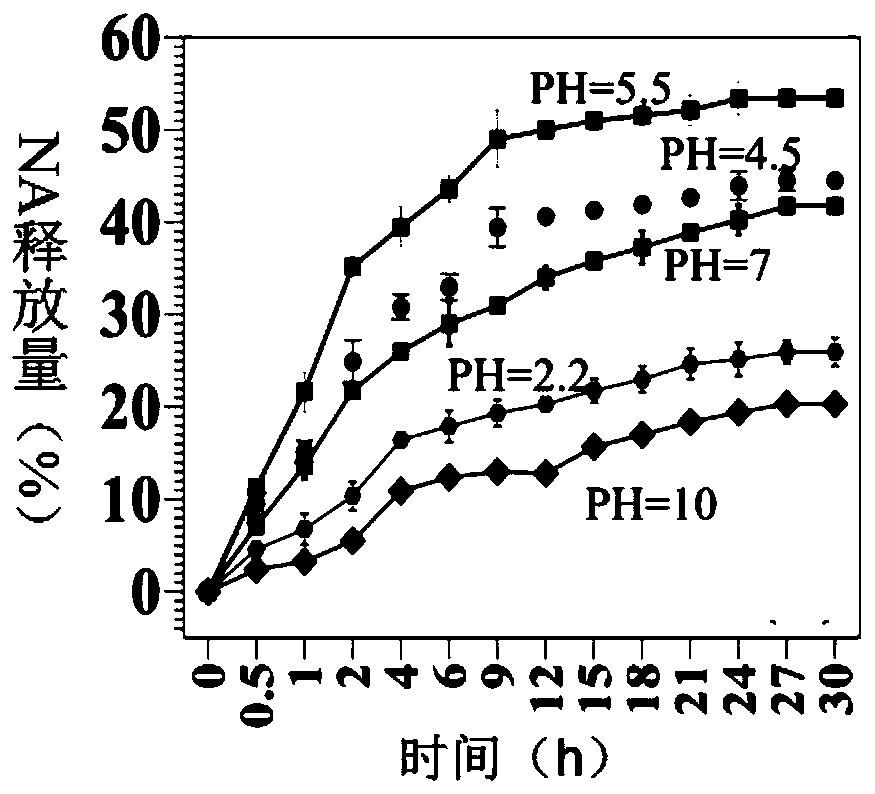

[0036]Weigh 1g of N-isopropylacrylamide, 1.5g of acrylamide, 0.01g of cross-linking agent N,N-methylenebisacrylamide and 0.025g of 2-aminoethyl methacrylate hydrochloride and dissolve in 50ml deionized water, add 0.1g nanocellulose solution and mix well. Under nitrogen protection, add initiator potassium persulfate (0.0032g) and 2-2'-azobis-(2-2-ylpropane hydrochloride) (0.00814g), and catalyst 1, 2 of 0.045ml - Bis(dimethylamino)ethane. Afterwards, the mixed solution was poured into a PVA (polyvinyl alcohol) template, and reacted at 25° C. for 8 hours to obtain a pH and temperature double stimulus-responsive nanocellulose hydrogel film with a thickness of 0.08 mm and a tensile strength of 5.4 Kpa. The obtained hydrogel film was soaked in distilled water to remove unreacted monomers, and the distilled water was changed every 4 hours for 3 days. Subsequently, the hydrogel was dried in an oven at 30° C. for 24 hours, and then 1.25 g of the xerogel film was soaked in 100 ml of ...

Embodiment 3

[0038] Weigh 1.25g of N-isopropylacrylamide, 1.86g of acrylamide, 0.012g of crosslinking agent N,N-methylenebisacrylamide and 0.038g of 2-aminoethyl methacrylate hydrochloride Dissolve in 40ml deionized water, add 0.078g nanocellulose solution and mix well. Under the protection of nitrogen, add initiator potassium sulfate (0.004g) and 2-2'-azobis-(2-2-ylpropane hydrochloride) (0.01g), and 0.056ml of catalyst 1, 2- Bis(dimethylamino)ethane. Afterwards, the mixed solution was poured into the PVA template and reacted at 30°C for 6 hours to obtain a nanocellulose hydrogel film with dual stimulus response to pH and temperature, with a thickness of 0.075mm and a tensile strength of 3.36Kpa. The obtained hydrogel film was soaked in distilled water to remove unreacted monomers, and the distilled water was replaced every 4 hours for 3 days. Subsequently, the hydrogel film was freeze-dried for 24 hours, and then 0.625 g of the dry gel film was soaked in 50 ml of 1 mg / mL sodium benzoat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com