Zinc layer surface chromium-free environmental protection passivation processing liquid and preparation method and use thereof

A passivation treatment and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of poor compactness and continuity, poor metal substrate adhesion, insufficient film tension, etc., to improve compatibility and stability, Broad promotion and application prospects, good film-forming stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

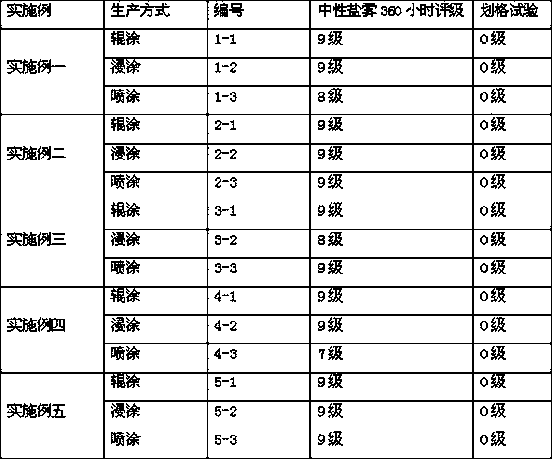

Examples

preparation example Construction

[0032] The present invention provides a chromium-free and environmentally friendly passivation treatment solution for the surface of zinc layer and its preparation method, wherein the chromium-free and environment-friendly passivation treatment solution for the surface of zinc layer is composed of: special doped resin 1-10% by mass percentage , coupling agent 1-8%, water-based nano-sol 1-10%, modified hydroxyl nano-phyllosilicate powder 0.5-5%, metal chelating agent 0.1-3%, diluent 5-20%, dispersant 0.5-3%, thickener 0.5-3%, PH regulator 0.3-2%, and the rest is water.

[0033] Among them, the special doped resins are: acrylate silicone hybrid resin, polyurethane silicone hybrid resin, epoxy silicone hybrid resin, silicon alkyne hybrid resin, silicone-inorganic silicon hybrid resin, titanium oxide modified MQ hybrid resin, acrylate modified polyurethane resin, alkyd silicone hybrid resin, silsesquioxane polyvinyl silicone resin, polyester modified alkyd silicone hybrid resin, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com