High-phosphorus-nitrogen co-doped three-dimensional porous carbon block and preparation method and application thereof

A three-dimensional porous, co-doping technology, used in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems of difficult to achieve high phosphorus atom content and controllable doping, and achieve excellent reversible specific capacity, Excellent electrochemical performance, the effect of increasing nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

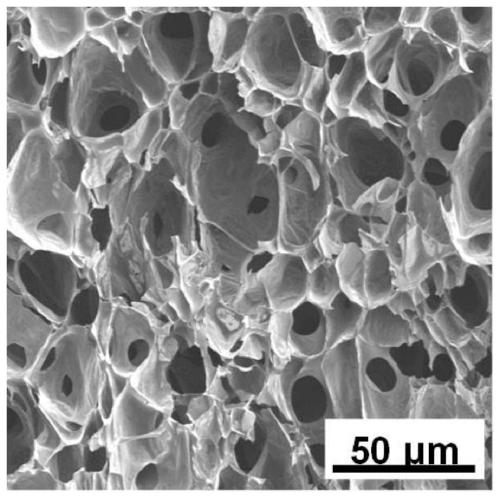

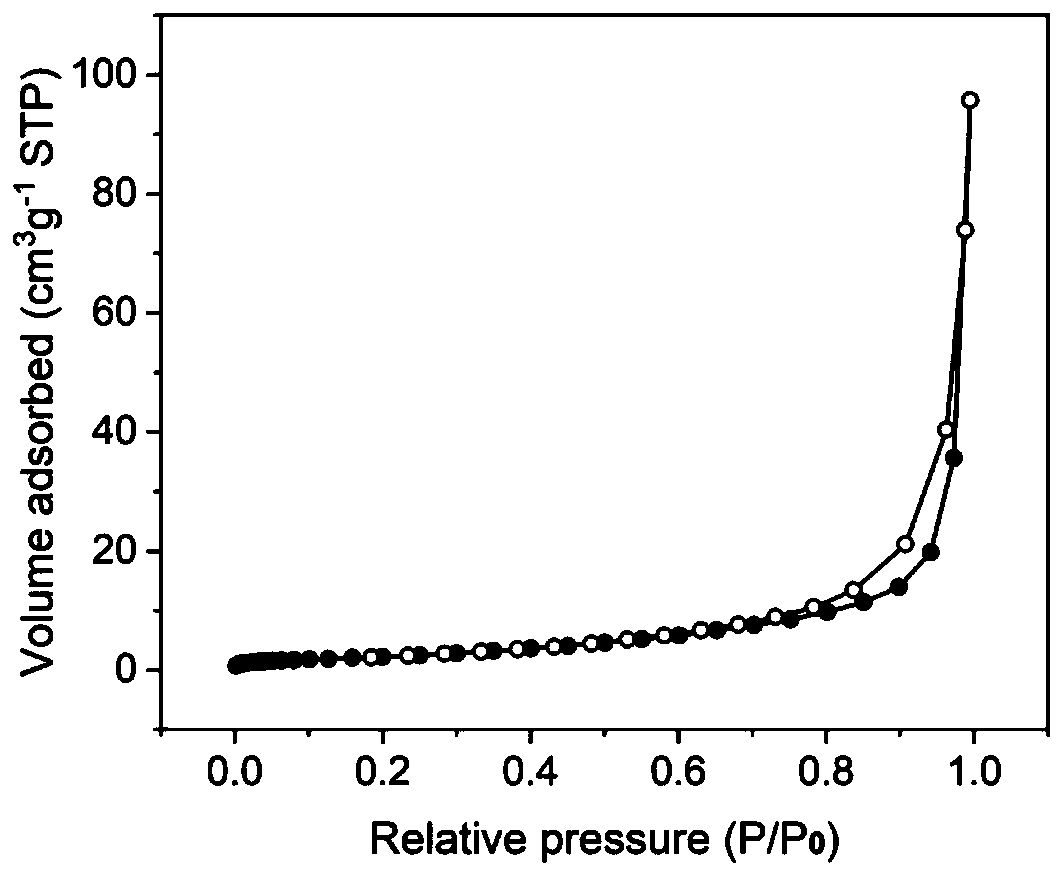

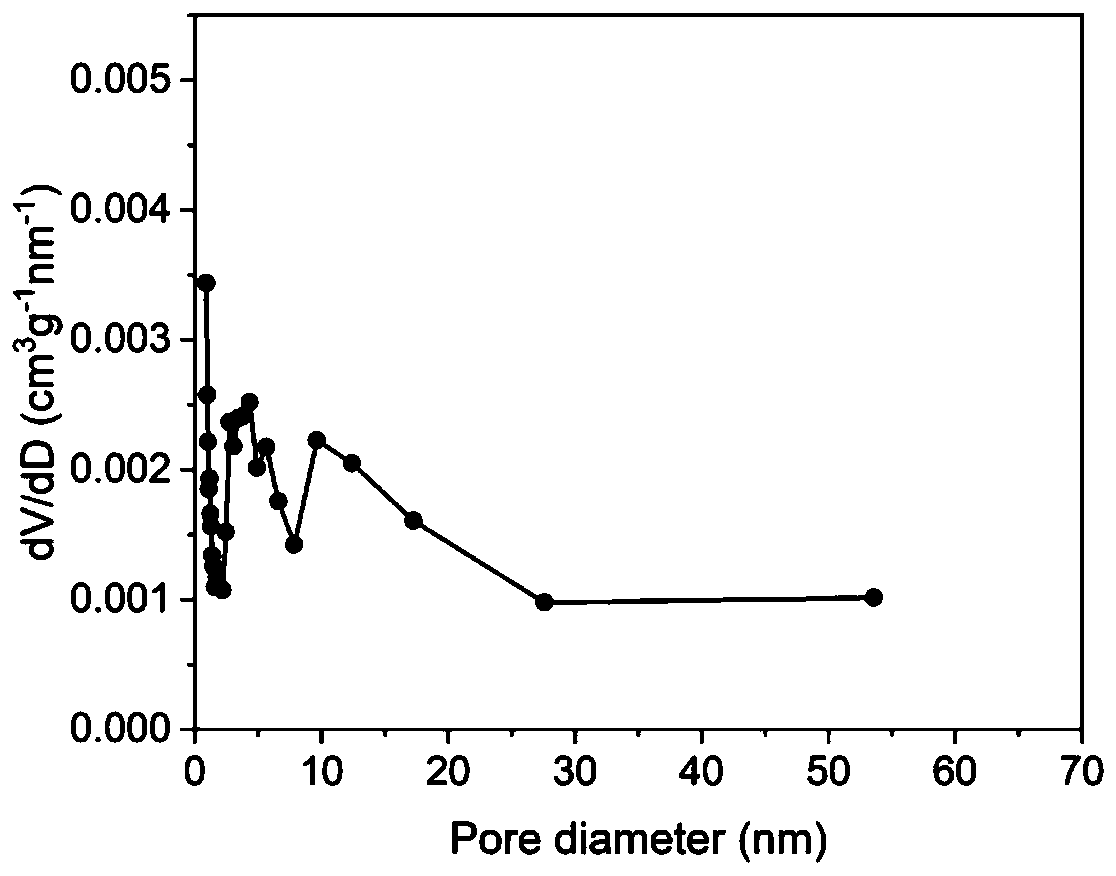

[0048] The preparation method of the high phosphorus-nitrogen co-doped three-dimensional porous carbon block (named PN-PCM) for the negative electrode of the potassium ion battery involved in the present embodiment comprises the following steps:

[0049] (1) Fully dissolve polyacrylonitrile powder and polymethyl methacrylate in dimethyl sulfoxide at a mass ratio of 4:1, the total amount of polyacrylonitrile powder and polymethyl methacrylate and solvent dimethyl The mass ratio of radical sulfoxide is 1:9. Part of the solvent is evaporated, and after trimming, hot pressing at 160°C and 10Mpa for 10 minutes to form a block and punching, the polyacrylonitrile-based foam is obtained by foaming with supercritical carbon dioxide. The foaming condition of supercritical carbon dioxide is: in the autoclave, CO 2 Afterwards, the temperature was raised to 140°C, and the pressure was increased to 31.09Mpa, kept for 1.5h and then quickly released.

[0050] (2) Prepare a 20g / L aqueous sol...

Embodiment 2

[0056] The preparation method of the high phosphorus-nitrogen co-doped three-dimensional porous carbon block (named PN-PCM-L) for the negative electrode of the potassium ion battery involved in the present embodiment comprises the following steps:

[0057] (1) Fully dissolve polyacrylonitrile powder and polymethyl methacrylate in dimethyl sulfoxide at a mass ratio of 4:1, the total amount of polyacrylonitrile powder and polymethyl methacrylate and solvent dimethyl The mass ratio of radical sulfoxide is 1:9. Part of the solvent was evaporated, and polyacrylonitrile-based foam was obtained by foaming with supercritical carbon dioxide after trimming, hot pressing at 160°C and 10Mpa for 10 minutes and punching. The foaming condition of supercritical carbon dioxide is: in the autoclave, CO 2 Afterwards, the temperature was raised to 140°C, and the pressure was increased to 31.09Mpa, kept for 1.5h and then quickly released.

[0058] (2) Prepare a 20g / L aqueous solution of hydroxyl...

Embodiment 3

[0064] The preparation method of the high phosphorus-nitrogen co-doped three-dimensional porous carbon block (named PN-PCM-H) for the negative electrode of the potassium ion battery involved in the present embodiment comprises the following steps:

[0065] (1) Fully dissolve polyacrylonitrile powder and polymethyl methacrylate in dimethyl sulfoxide at a mass ratio of 4:1, the total amount of polyacrylonitrile powder and polymethyl methacrylate and solvent dimethyl The mass ratio of radical sulfoxide is 1:9. Part of the solvent was evaporated, and polyacrylonitrile-based foam was obtained by foaming with supercritical carbon dioxide after trimming, hot pressing at 160°C and 10Mpa for 10 minutes and punching. The foaming condition of supercritical carbon dioxide is: in the autoclave, CO 2 Afterwards, the temperature was raised to 140°C, and the pressure was increased to 31.09Mpa, kept for 1.5h and then quickly released.

[0066] (2) Prepare a 20g / L aqueous solution of hydroxyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com