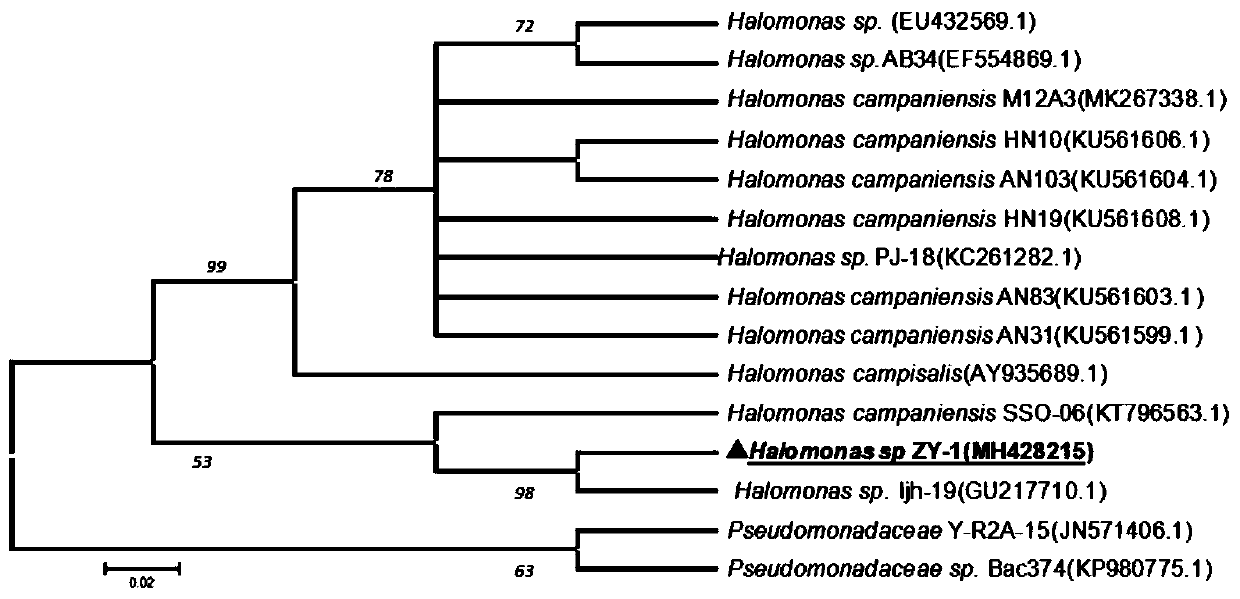

Cheap synthesis of biodegradable mulching film from straws and illegal cooking oil by using halomonas sp ZY-1

A technology for degrading mulch and halomonas, applied in the field of agricultural materials, can solve the problems of white pollution, petrochemical plastic consumption of petrochemical energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

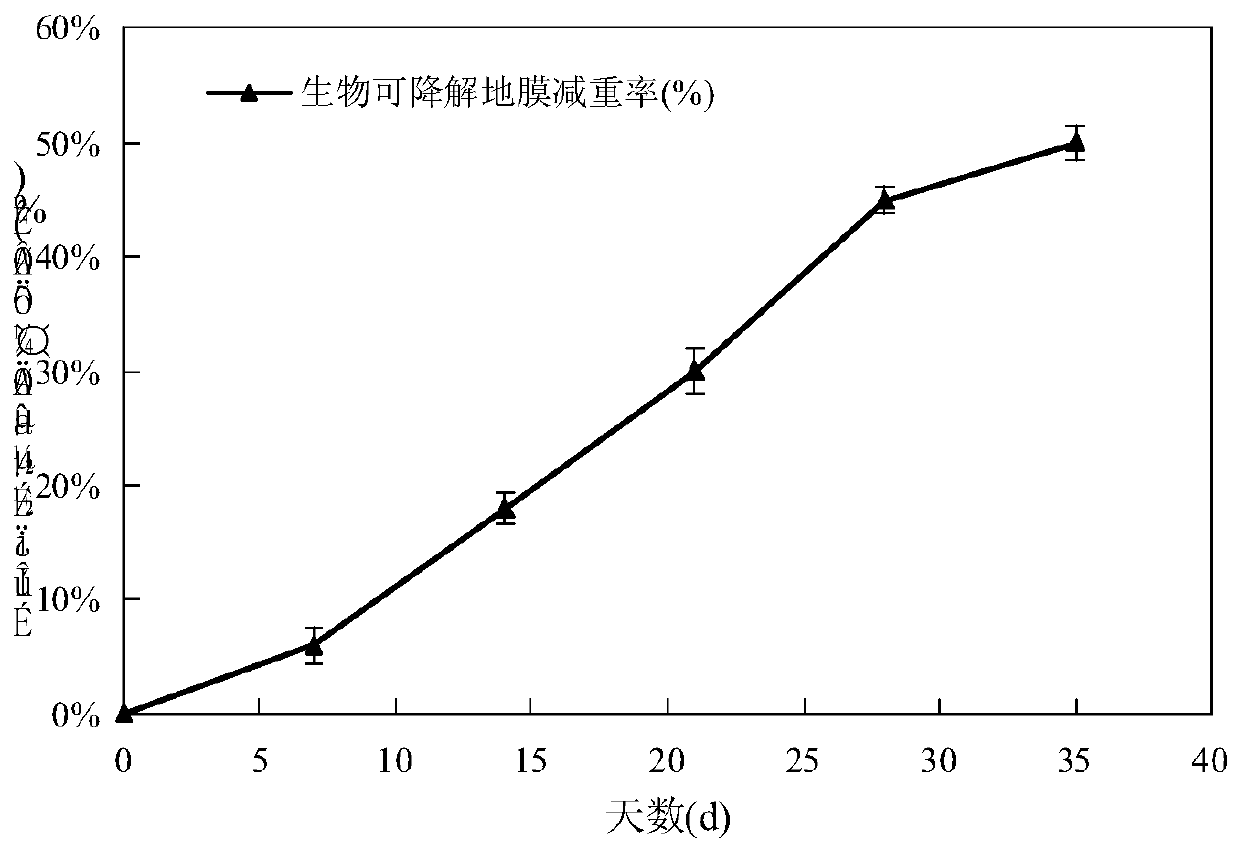

[0026] Embodiment 1, the natural degradation situation of biodegradable plastic film

[0027] In order to simulate the degradation of biodegradable mulch film under natural conditions, this study used the weight loss rate of biodegradable mulch film buried in the soil to investigate its degradation ability.

[0028] (1) Take 3 prepared biodegradable mulch samples, each 20-30 mg, and record it as the initial mass M 0 .

[0029] (2) Place biodegradable plastic film samples in 20-25°C environment, 15-20cm deep cultivated land, take out the samples every 7 days to remove the surface soil, and place them in an oven at 40-55°C for drying treatment Weigh and record as Mn.

[0030] (3) The weight loss rate of biodegradable plastic film is calculated as follows:

[0031]

[0032] Degradation as figure 2 , in dry air, the 35d weight loss rate is 0.5%. At 20-25°C, the degradable plastic film is deeply buried in 15-20cm of cultivated soil, and the 35d weight loss rate reaches 40-5...

Embodiment 2

[0033] Embodiment 2, Halomonas sp.ZY-1 is not sterilized synthetic polyester class material in SBR reactor

[0034] (1) Pass the crushed straw through a 100-200 mesh fine sieve to obtain straw powder, soak 75-140g of straw powder per 1L of 1-2mol / L NaOH solution, treat with high temperature and high pressure for 2-4h, and centrifuge at 4000-6000r / min for 10min to collect the straw Supernatant, the main components are 2.5-6% cellulose, 15-30% xylose, 16-25% lignin, and 1-5% acid-soluble lignin;

[0035](2) MS medium components are: straw supernatant 750-800mL / L, waste oil 17-20mL / L, yeast extract 5-10g / L, Na 2 HPO 4 12H 2 O 10-15g / L, KH 2 PO 4 1-2g / L, NH 4 Cl 1-2g / L, MgSO 4 0.1-1.5g / L, Fe(III)-NH 4 -Citrate 0.05-0.1 g / L, CaCl 2 2H 2 O 0.02-0.1g / L, ZnSO 4 ·7H 2 O 0.1-0.5g / L, NaCI 60-70g / L, pH adjusted to 9.5-11, directly used to cultivate Halomonas sp.ZY-1 without sterilization;

[0036] (3) In an SBR reactor with a drainage ratio of 10 / 13, inoculate 1-5% of Halomo...

Embodiment 3

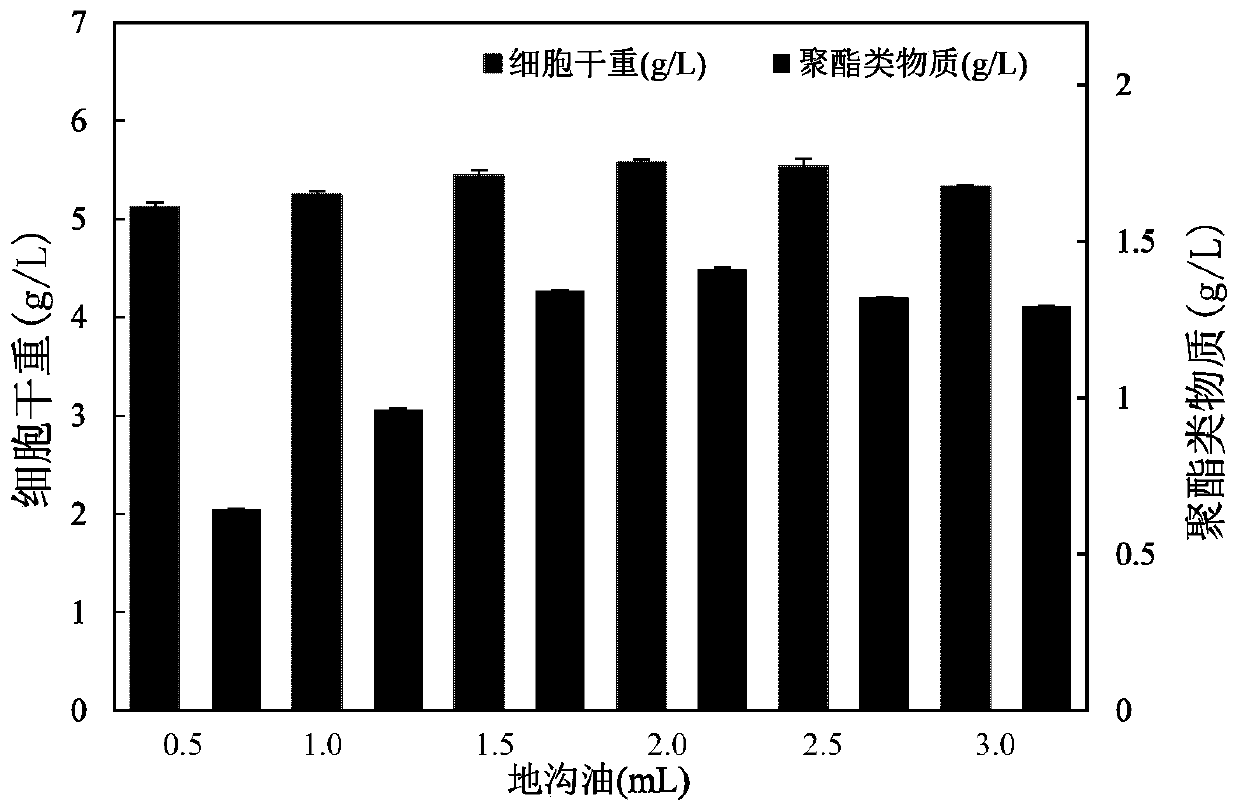

[0039] Example 3, Halomonas sp.ZY-1 uses rice straw and waste oil to synthesize polyester substances

[0040] According to the analysis results of the yield of polyesters in Example 2, the yield of polyesters synthesized from straws is low, and the film-forming properties of polyesters are poor. Add waste oil (composition 90-92% oleic acid, 3-4% triglyceride, 2-3% vegetable oil, 2-3% animal oil) for improvement, and use straw and waste oil as carbon sources to prepare MS medium.

[0041] (1) Straw and waste oil gradient MS medium configuration: 800mL / L straw supernatant, yeast extract 5g / L, Na 2 HPO 4 12H 2 O 10-15g / L, KH 2 PO 4 1-2g / L, NH 4 Cl 1-2g / L, MgSO 4 0.1-1.5g / L, Fe(III)-NH 4 -Citrate 0.05-0.1g / L, CaCl 2 2H 2 O 0.02-0.1g / L, ZnSO 4 ·7H 2 O 0.1-0.5g / L, waste oil is 5mL / L, 10mL / L, 15mL / L, 20mL / L, 25mL / L, 30ml / L;

[0042] (2) Put Halomonas sp.ZY-1 seed solution activated overnight in LB medium into MS medium with 1-5% inoculation amount, and cultivate 80- 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com