Synthesis process of 2, 2, 4-trimethyl-1, 3pentanediol dibutyrate and application of 2, 2, 4-trimethyl-1, 3pentanediol dibutyrate in interior wall latex paint

A technology of pentanediol dibutyrate and trimethyl, which is applied in the application field of interior wall latex paint, can solve the problems of not meeting the environmental protection release requirements of TVOC, affecting the fetus in the reproductive system, and harmful to aquatic organisms, so as to reduce the Effects of VOC, reduced film forming temperature, and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]

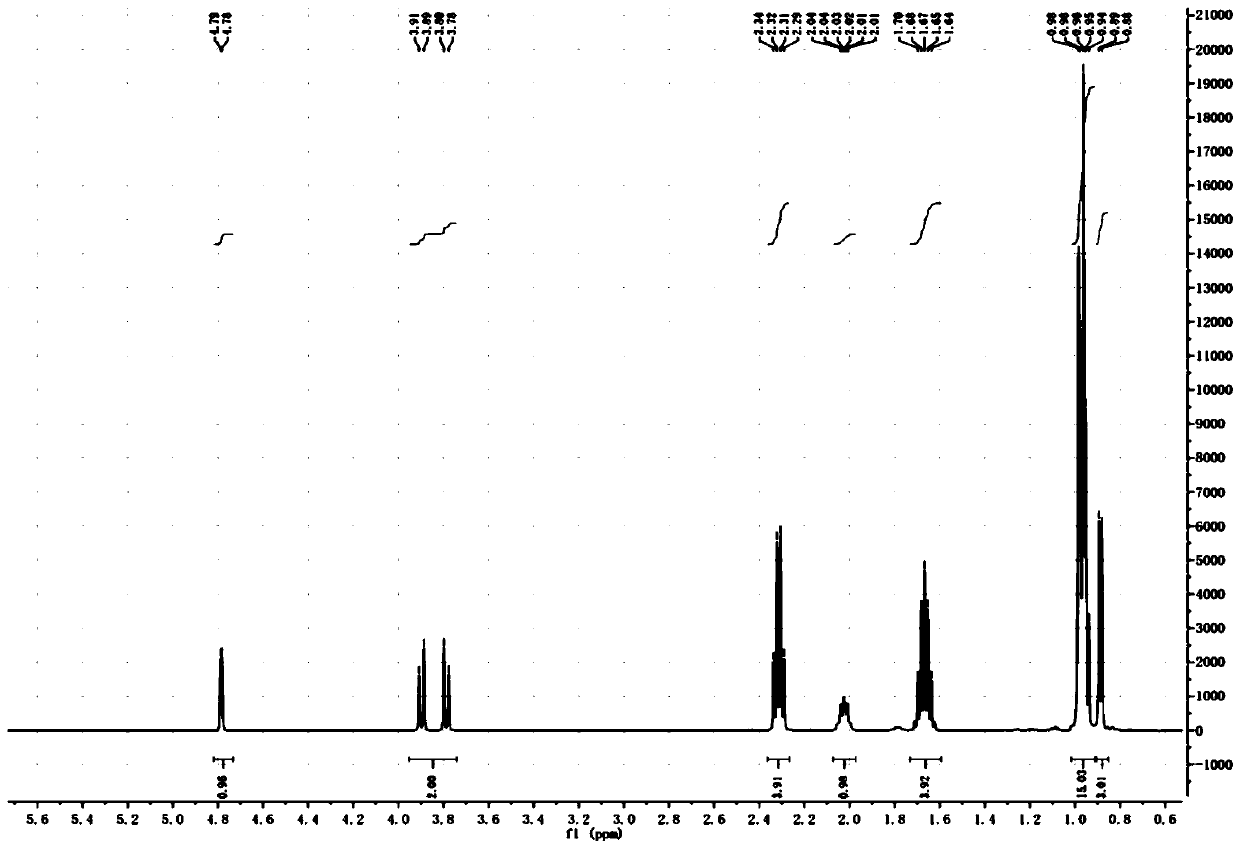

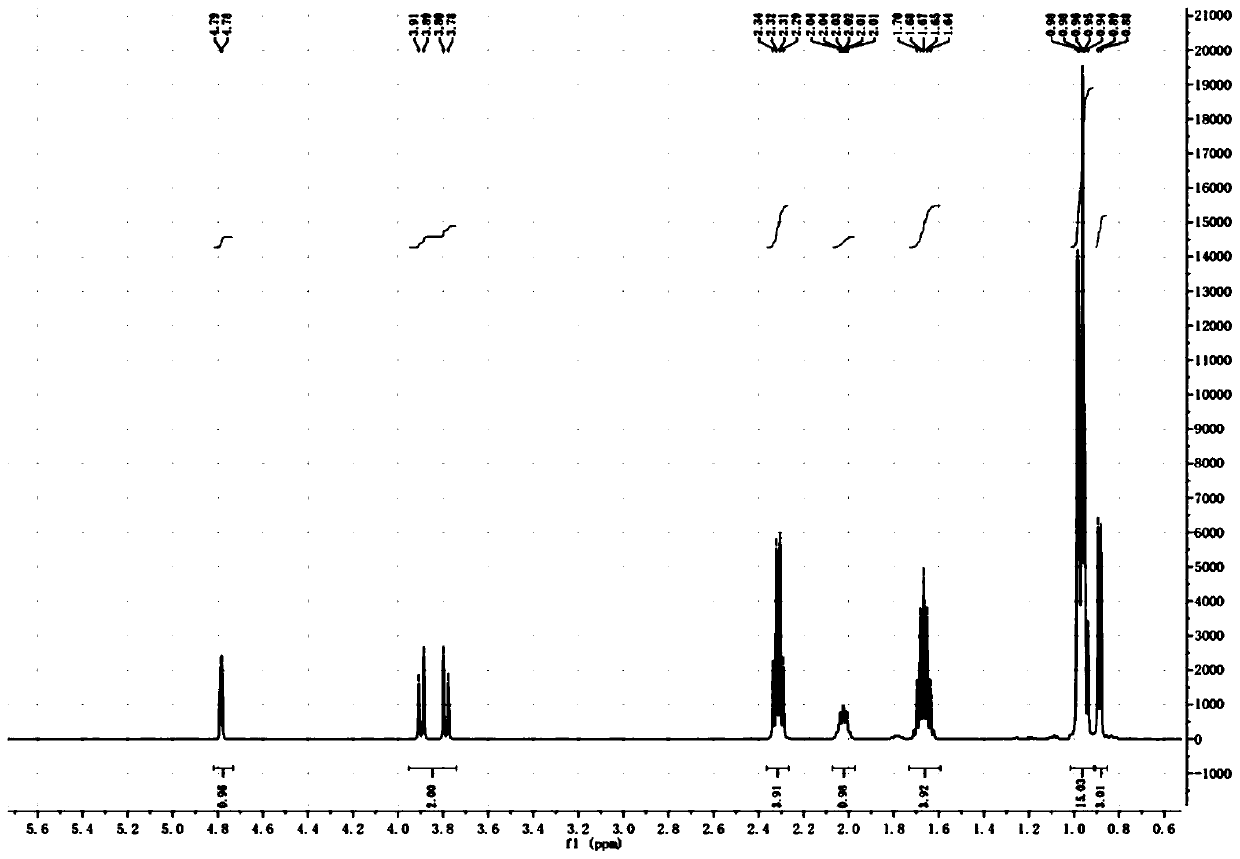

[0021] In a 500mL three-necked flask equipped with a thermometer, agitator and a reflux condenser, 2,2,4-trimethyl-1,3-pentanediol and butyric acid were added to the three-necked flask in a ratio of 1:2 of the feeding substances, And at the same time add 0.3mol% catalyst NaHSO 4 ·H 2 O-NaH 2 PO 4 (Based on 2,2,4-trimethyl-1,3-pentanediol), and nitrogen protection was introduced, and then the reaction was carried out at 160 ° C for 8 h; the reaction was stopped, and the reaction solution was cooled to room temperature using a Buchner funnel. Suction filtration, the obtained filtrate was extracted through a separatory funnel, washed three times with saturated aqueous sodium hydroxide solution and deionized water, respectively, and the impurities were removed by rotary evaporation at 140 ° C and -0.1 MPa by a rotary evaporator, and finally 2 was obtained. ,2,4-Trimethyl-1,3-pentanediol dibutyrate, RTC-300 as a film-forming aid product, the product yield is 97%, se...

Embodiment 2

[0024] On the basis of Example 1, the catalyst was changed to NaHSO 4 ·H 2 O-KH 2 PO 4 , and the rest remain unchanged to obtain 2,2,4-trimethyl-1,3 pentanediol dibutyrate, which is a film-forming auxiliary product RTC-300, and the product yield is 95%.

[0025]On the basis of Example 1, the reaction at 160 °C for 8 h was replaced by the reaction at 170 °C for 5 h, and the rest remained unchanged to obtain 2,2,4-trimethyl-1,3-pentanediol dibutyrate, which was Film auxiliary product RTC-300, the product yield is 93%.

Embodiment 3

[0029] Water and bactericide are added to the high-speed disperser in turn, and dispersed at 600rpm for 5min; then add dispersant, defoamer, water retention agent, film-forming aid, and wetting agent in sequence, and continue to disperse at 600rpm for 5min; then add powder, fiber PH regulator, dispersed at 1500rpm for 60 minutes, stopped dispersion, added emulsion and thickener, dispersed at 1500rpm for 10 minutes, filtered to obtain the finished water-based interior wall paint, fineness ≤45μm.

[0030] The amount of each raw material is shown in Table 1, and the total amount is 1KG. The creativity of the present invention is to use it as a coating film-forming auxiliary, and other coating components are existing conventional products.

[0031] Table 1 Water-based interior wall paint formulation

[0032]

[0033]

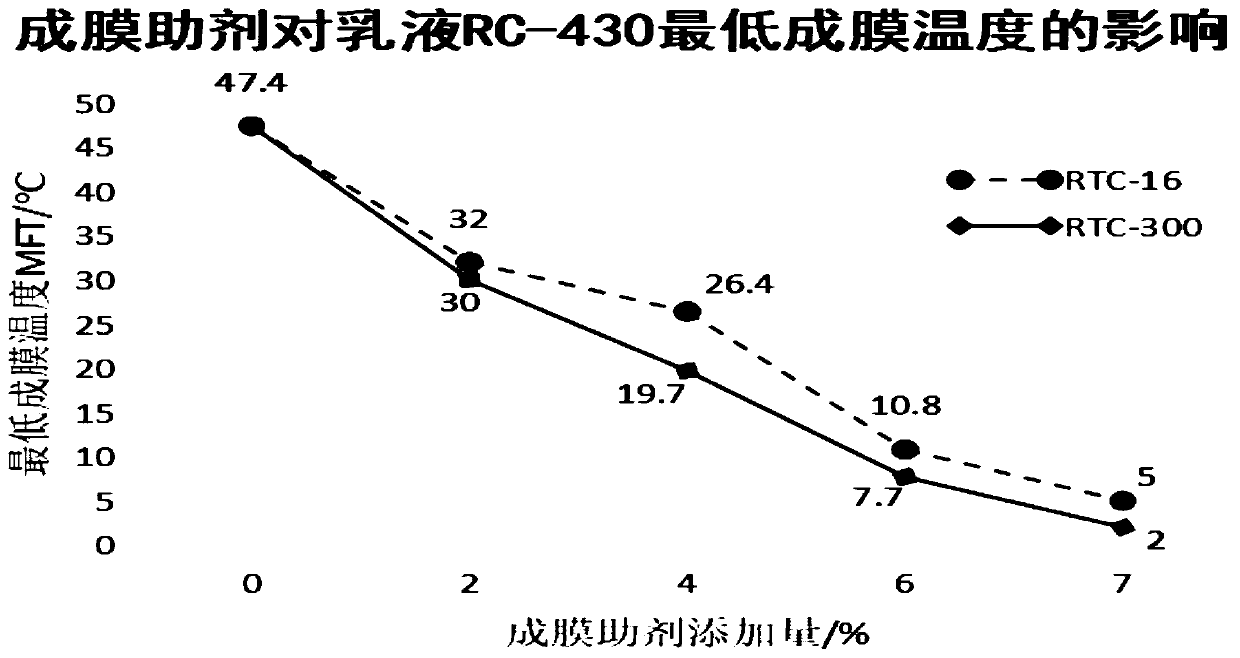

[0034] Film-forming efficiency test (2,2,4-trimethyl-1,3-pentanediol-bisisobutyrate for RTC-16, 2,2,4-trimethyl-1,3-pentane for RTC-300 Diol-dibutyrate), sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com