Water-based easy-to-radiate antibacterial insulating coating and preparation method thereof

An insulating coating, water-based technology, used in antifouling/underwater coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem of poor insulation of heat-dissipating coatings, easy mildew on cable surfaces, and endangering the health of users. and other problems, to achieve the effect of small dielectric loss, improved precision, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

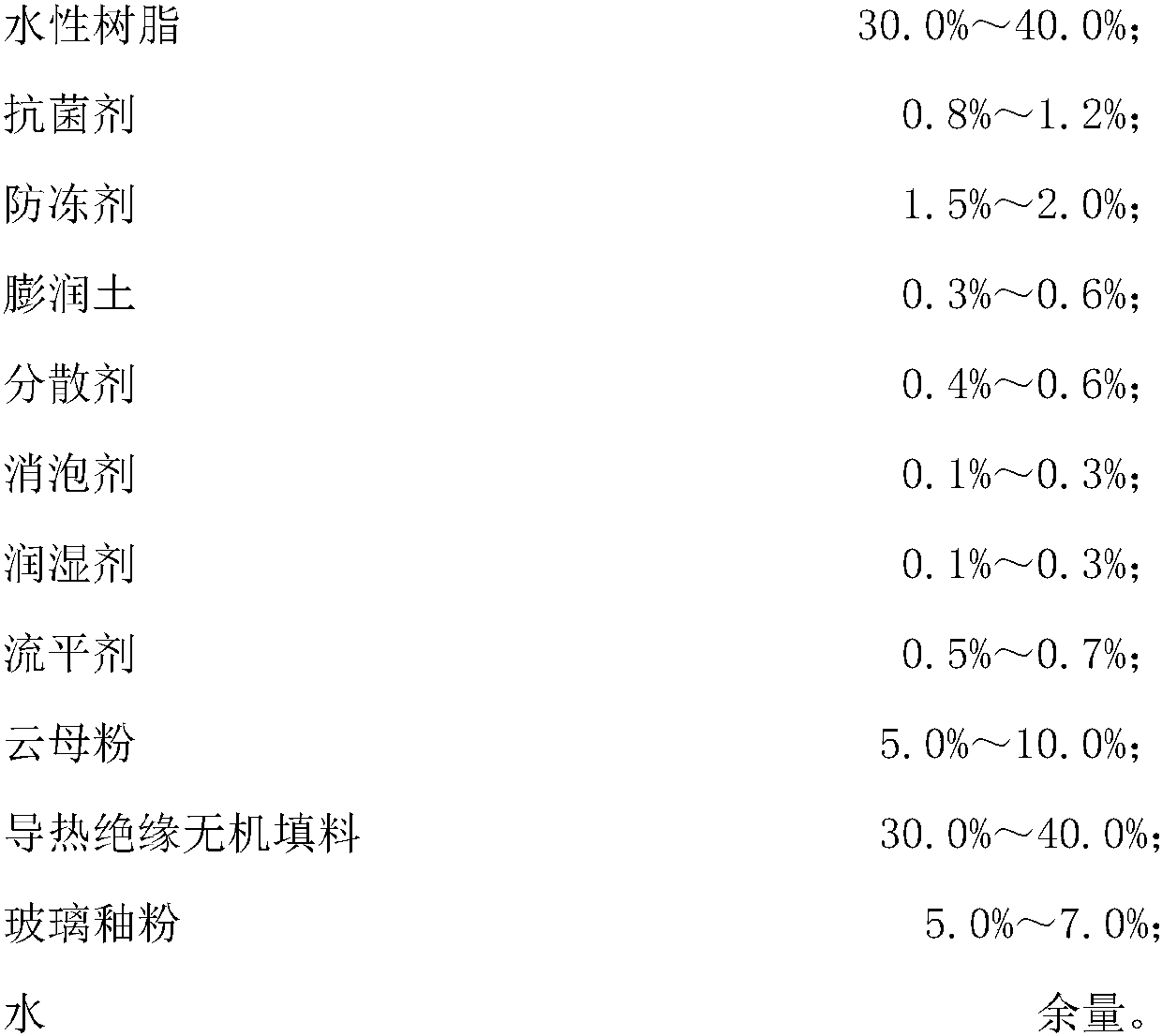

[0022] A water-based heat-dissipating and antibacterial insulating coating comprises the following components:

[0023]

[0024] Concrete preparation method is as follows:

[0025] At a speed of 200-300r / min, add sodium bentonite, propylene glycol, sodium pyrophosphate, paraffin-based mineral oil, and alkyl polyoxyethylene ether into the water, and stir for 5-10 minutes; then the speed changes to 1200-1300r / min, and the Add mica powder, aluminum nitride, and glass glaze powder, and continue to stir for 15-20 minutes; then change the speed to 500-600r / min, and add water-based acrylic resin, 2-methyl-4-isothiazolin-3-one, and silicone The leveling agent is added in sequence, and the stirring is continued for 10-15 minutes to obtain a water-based heat-dissipating antibacterial insulating coating.

Embodiment 2

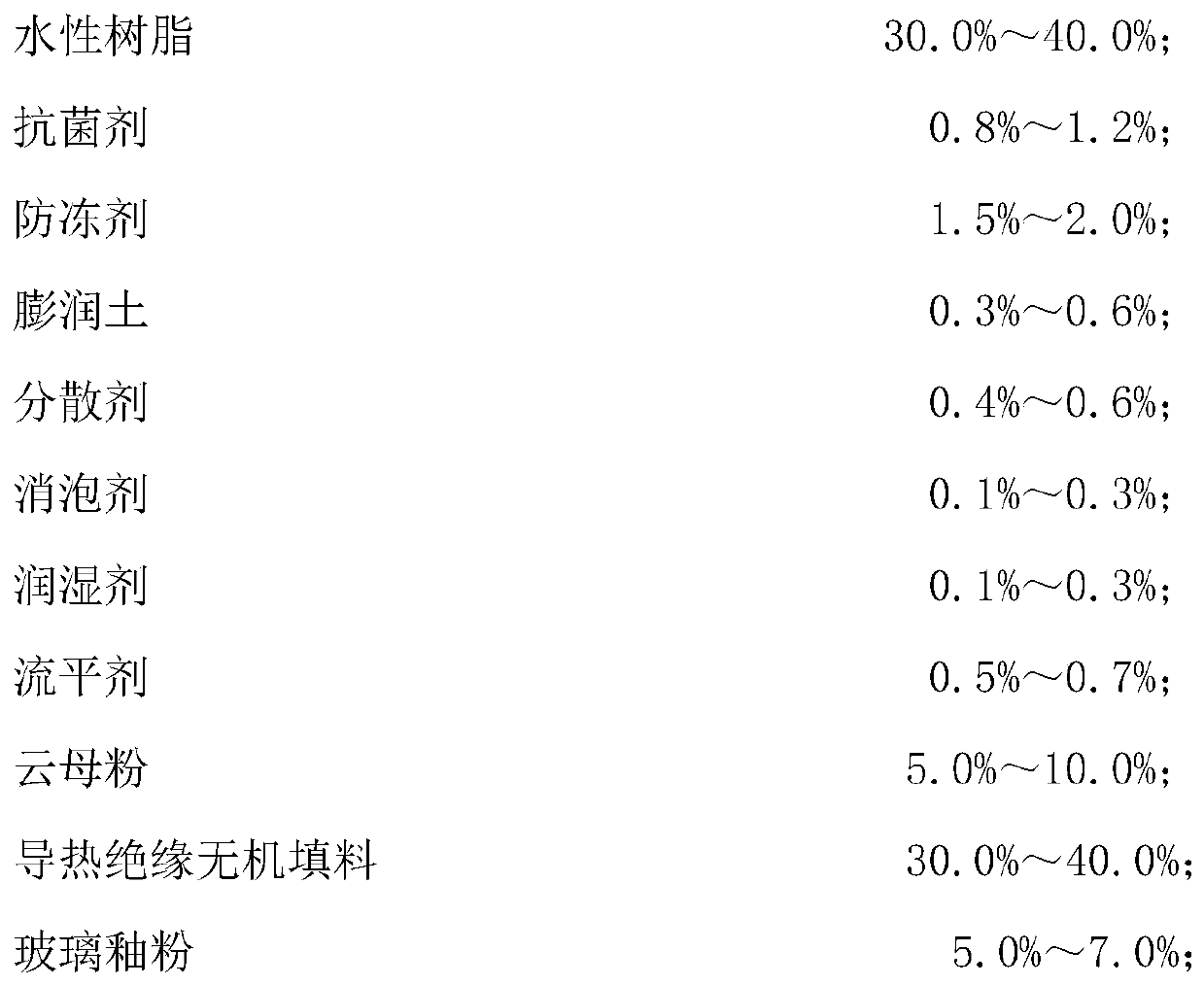

[0033] A water-based heat-dissipating and antibacterial insulating coating comprises the following components:

[0034]

[0035] Concrete preparation method is as follows:

[0036] At a rotational speed of 200-300r / min, add calcium-based bentonite, ethylene glycol, alkyl sulfate, polyether-modified dimethylsiloxane, and alkylaryl polyether into the water, and stir for 5-10min; Change to 1200-1300r / min, add mica powder, silicon nitride, glass glaze powder, continue to stir for 15-20min; then change the speed to 500-600r / min, add water-based epoxy resin, 2-n-octyl-4 - Isothiazolin-3-one and modified acrylic acid leveling agent are added in sequence, and stirring is continued for 10-15 minutes to obtain a water-based heat-dissipating antibacterial insulating coating.

Embodiment 3

[0044] A water-based heat-dissipating and antibacterial insulating coating comprises the following components:

[0045]

[0046] Concrete preparation method is as follows:

[0047] At the speed of 200-300r / min, add hydrogen-based bentonite, ethylene glycol butyl ether, maleic anhydride copolymer, polysiloxane, and polyether-modified dimethylsiloxane into the water, and stir for 5-10min ; Then the rotating speed is changed to 1200-1300r / min, mica powder, boron nitride, glass glaze powder are added, continue to stir for 15-20min; then the rotating speed is changed to 500-600r / min, water-based polyurethane resin, phenylpropanisothiazoline Add -3-ketone and polyurethane leveling agent in sequence, and continue to stir for 10-15 minutes to obtain a water-based heat-dissipating antibacterial insulating coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com