Manufacturing method of magnetic film annular inductor

A technology of toroidal inductors and magnetic thin films, applied in the application of magnetic films to substrates, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of incompatibility with semiconductor processes and the inability of thin film inductors to achieve high inductance density, etc. Achieve the effect of realizing large-scale production, low environmental and equipment requirements, and high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

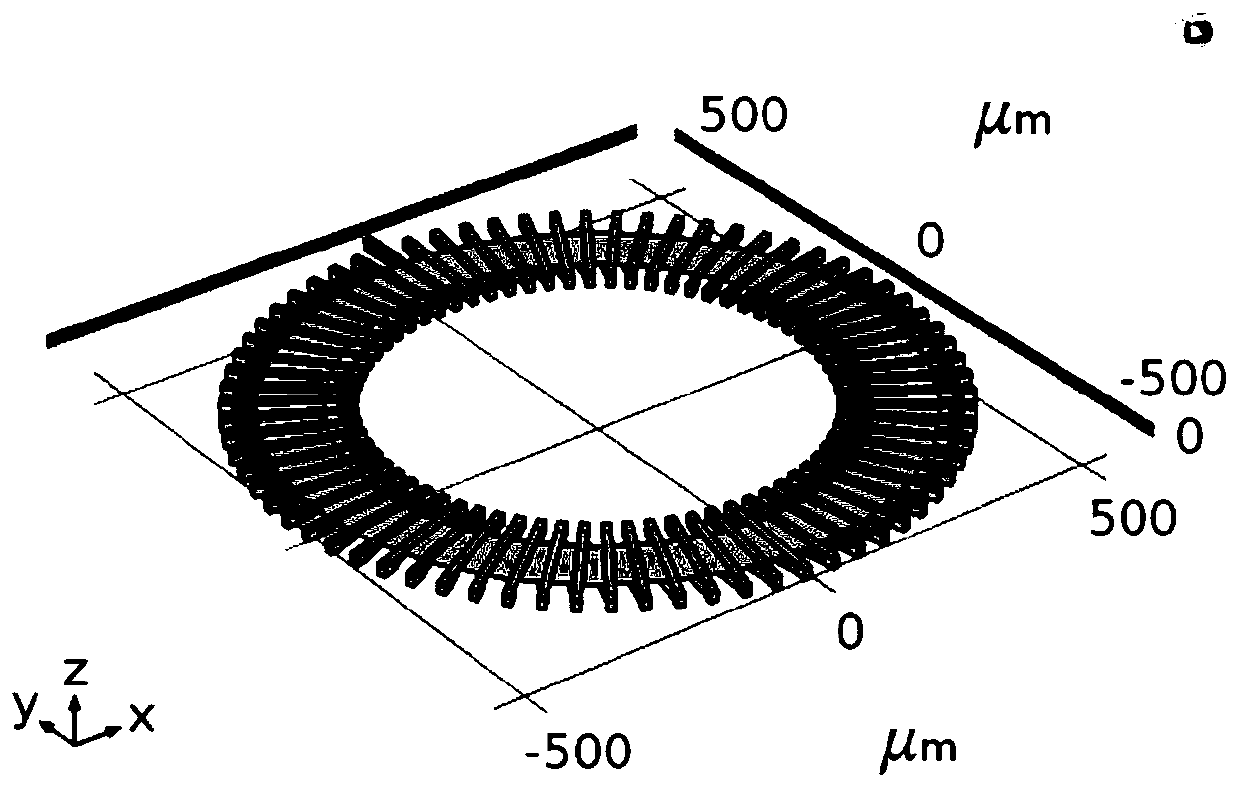

[0034] The invention provides a method for preparing a magnetic thin film toroidal inductor, the simulation model of the magnetic thin film toroidal inductor is as follows figure 1As shown, from bottom to top are silicon substrate, silicon dioxide insulating layer, lower coil, polyimide support layer, magnetic core film, polyimide support layer, upper coil, the upper coil and the lower coil pass through Holes are connected to obtain a copper coil. Wherein, the total number of turns of the copper coil is 72 turns, and the pitch of each turn is 5 degrees.

Embodiment

[0035] The preparation method of embodiment magnetic film ring inductor specifically comprises the following steps:

[0036] Step 1. Deposit a layer of 500nm thick silicon dioxide insulating layer on the high-resistance silicon substrate, then use the electroplating process to make the lower coil, and then deposit a layer of polyimide as the insulating support layer;

[0037] Step 2, preparing a magnetic core film by a spin spraying method;

[0038] 2.1 Sodium nitrite (NaNO 2 ) and sodium acetate (CH 3 COONa) was added into 1L of deionized water, and mixed uniformly to obtain the oxidation solution;

[0039] 2.2 Ferrous chloride (FeCl 2 ), nickel chloride (NiCl 2 ) and zinc chloride (ZnCl 2 ) into deionized water to prepare a reducing solution; the specific formulations of the oxidizing solution and the reducing solution are shown in Table 1-1:

[0040] Table 1-1

[0041]

[0042]

[0043] 2.3 Use an ultrasonic atomization system with an ultrasonic source power of...

Embodiment 2~4

[0049] The specific formulations of the oxidation solution and the reduction solution in steps 2.1 and 2.2 were changed, as shown in Table 1-2, to obtain Examples 2-4; other parameters and conditions of Examples 2-4 were the same as Example 1.

[0050] The formula of oxidation solution and reduction solution in table 1-2 embodiment 2~4

[0051]

[0052] The inductors prepared in Examples 1-4 were tested, and it was found that the Zn content in the film of Example 1 was the highest, so that the NiZn ferrite film had higher magnetization power and lower magnetization resistance, and the film permeability was higher , according to the ion occupancy distribution of spinel ferrite, Zn 2+ ions preferentially occupy the A site, with the Zn 2+ The increase of , the static magnetic moment of the material increases, and at the same time, the density of the film increases, and the saturation magnetization of the film increases. Therefore, by adjusting the Zn content in the film to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com