Self-supporting lithium-sulfur battery positive plate, preparation method thereof and lithium-sulfur battery

A lithium-sulfur battery, self-supporting technology, applied in the field of electrochemical energy storage, can solve the problems of reducing the mass energy density of the battery, the catalyst is difficult to function, and the interface contact is insufficient, so as to improve the mass energy density, reduce the activation potential, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

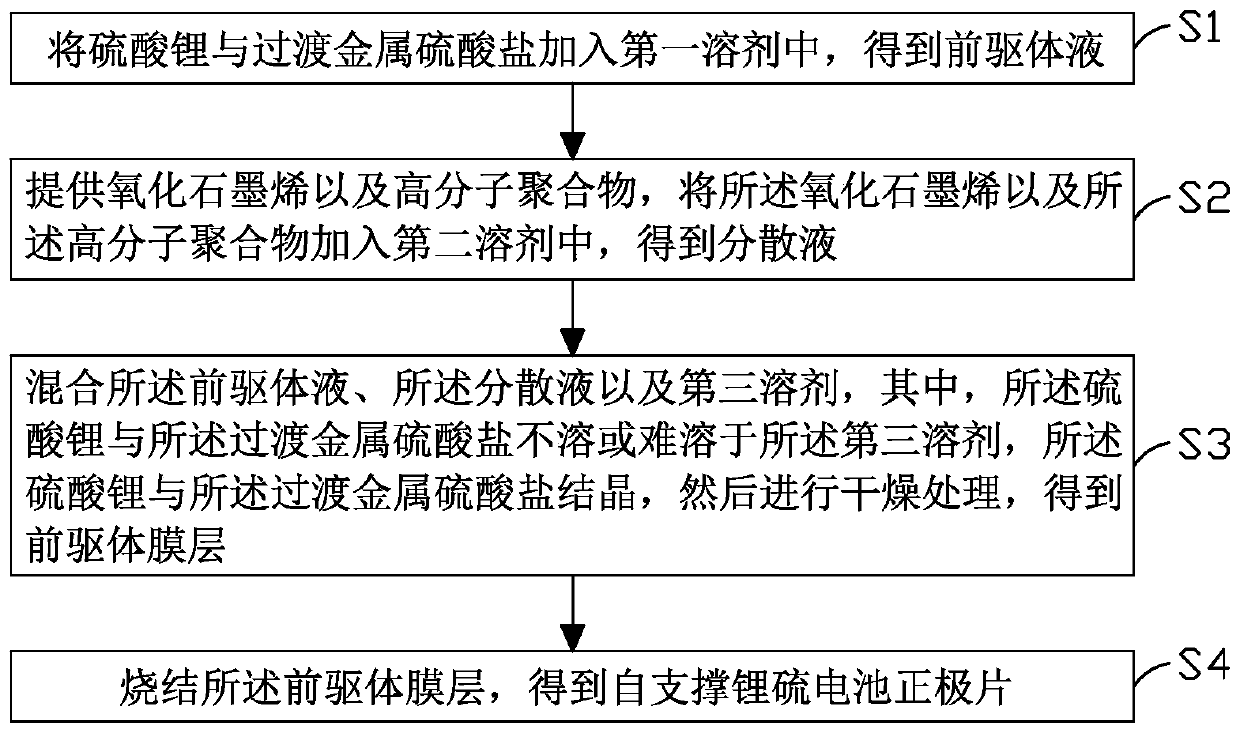

[0038] see figure 1 , the embodiment of the present application provides a method for preparing a positive electrode sheet of a self-supporting lithium-sulfur battery, comprising the following steps:

[0039] Step S1: adding lithium sulfate and transition metal sulfate into the first solvent to obtain a precursor liquid.

[0040] The transition metal sulfate includes at least one of nickel sulfate, cobalt sulfate, iron sulfate, molybdenum sulfate, titanium sulfate, vanadium sulfate, cadmium sulfate, manganese sulfate, copper sulfate, zinc sulfate and ruthenium sulfate. Described transition metal sulfate can be converted into transition metal sulfide in subsequent treatment process, for example nickel sulfate, cobalt sulfate, iron sulfate, molybdenum sulfate, titanium sulfate, vanadium sulfate, cadmium sulfate, manganese sulfate, copper sulfate, zinc sulfate and Ruthenium sulfate can be converted into nickel sulfide, cobalt sulfide, iron sulfide, molybdenum sulfide, titanium s...

Embodiment 1

[0064] Dissolve 250 mg of lithium sulfate monohydrate and 50 mg of cobalt sulfate pentahydrate (transition metal sulfate) in 5 mL of deionized water to obtain a precursor liquid.

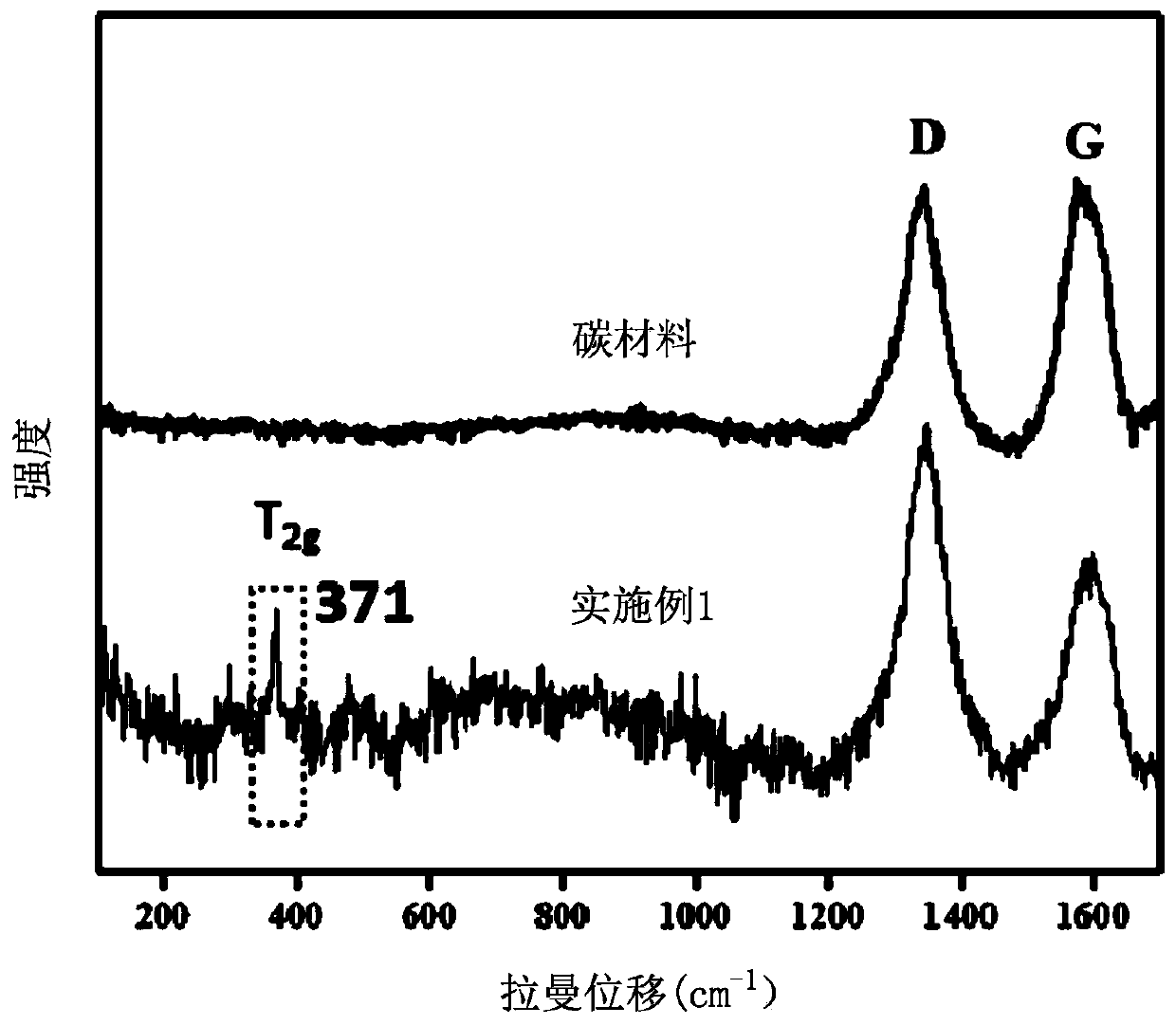

[0065] Weigh 250 mg of dry graphene oxide and place it in 50 mL of deionized water for ultrasonication for 1 h to obtain a graphene dispersion; 150 mg of polyvinylpyrrolidone (PVP) is dissolved in 10 mL of carbon nanotube slurry with a concentration of 1 mg / mL; the graphite The olefin dispersion liquid is added dropwise to the carbon nanotube slurry, and the graphene oxide gels as the dropwise addition proceeds to obtain the dispersion liquid.

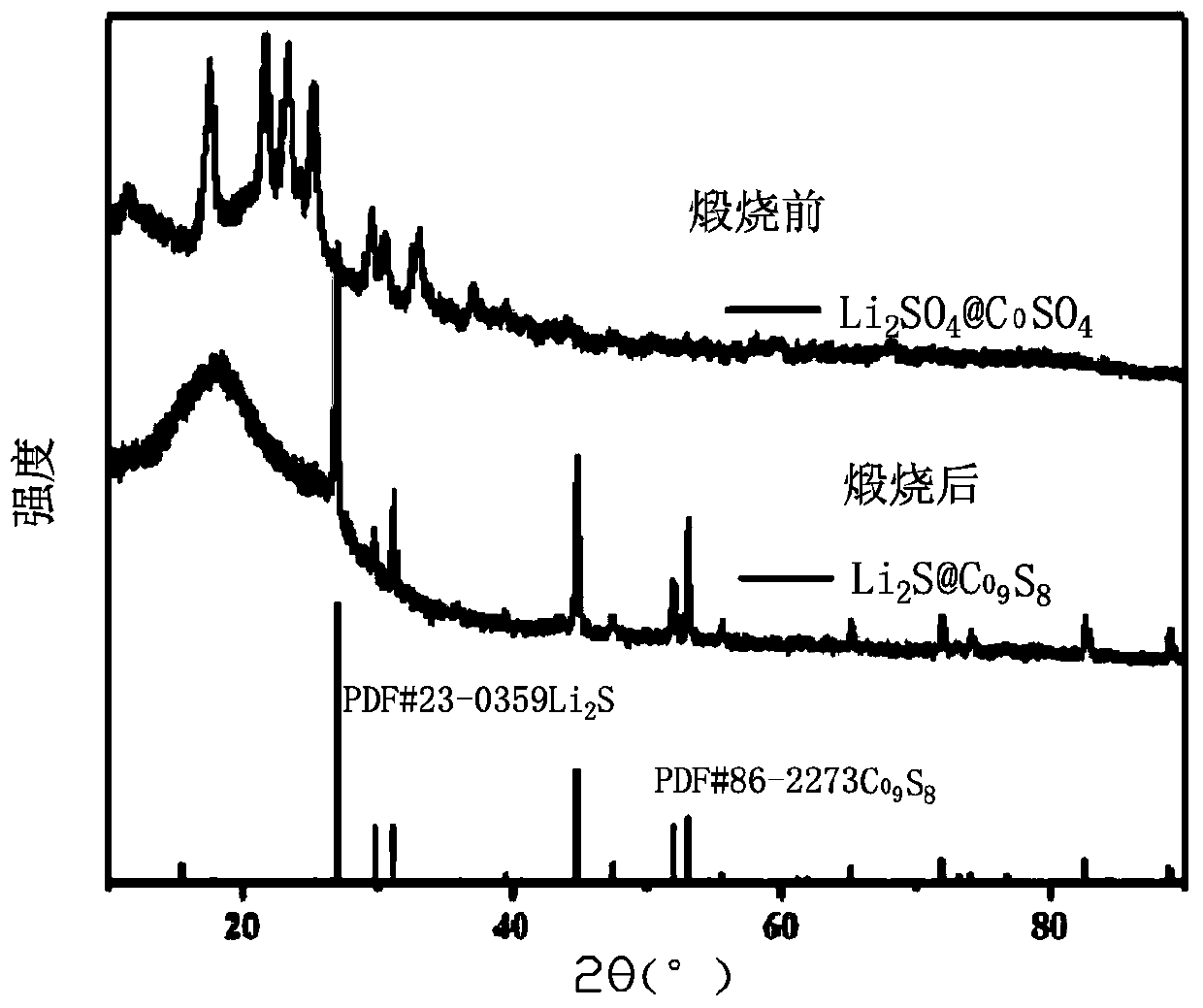

[0066] The precursor liquid and the dispersion liquid were mixed, and then added dropwise to countless ethanol for crystallization, the dropping speed was 1 drop per second, and then stirred for 10 min after the dropping was completed. Then it was centrifuged at a speed of 10000r / min, placed in a polytetrafluoroethylene vessel, and dried at a temperature of ...

Embodiment 2

[0069] The difference from Example 1 is that the transition metal sulfate is nickel sulfate.

[0070] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com