Preparation and application of titanium-based metal organic framework modified diaphragm

An organic framework and base metal technology, which is applied to the diaphragm material for lithium-sulfur batteries and the fields of preparation and application thereof, can solve the problems of complex preparation process, and achieve the effects of simple preparation process, improved kinetics, and low reversible capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Include the following steps:

[0033] (1) Weigh 3g of terephthalic acid powder and add it to 54mL of N,N-dimethylformamide and 6mL of anhydrous methanol, add 1.56mL of tetrabutyl titanate while stirring, and continue stirring for 3 hours to obtain a mixed solution.

[0034] (2) Transfer the mixed solution in step 1 to a hydrothermal reaction kettle for synthesis, set the oven temperature to 150°C, and the reaction time to 24h, and take it out after cooling to room temperature.

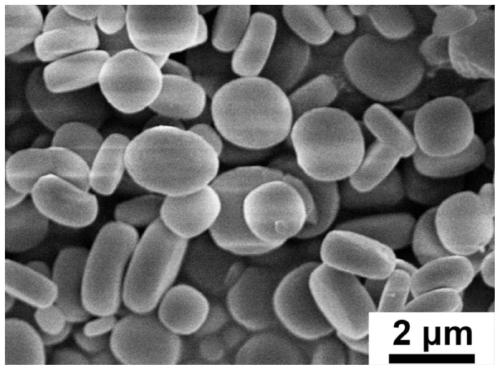

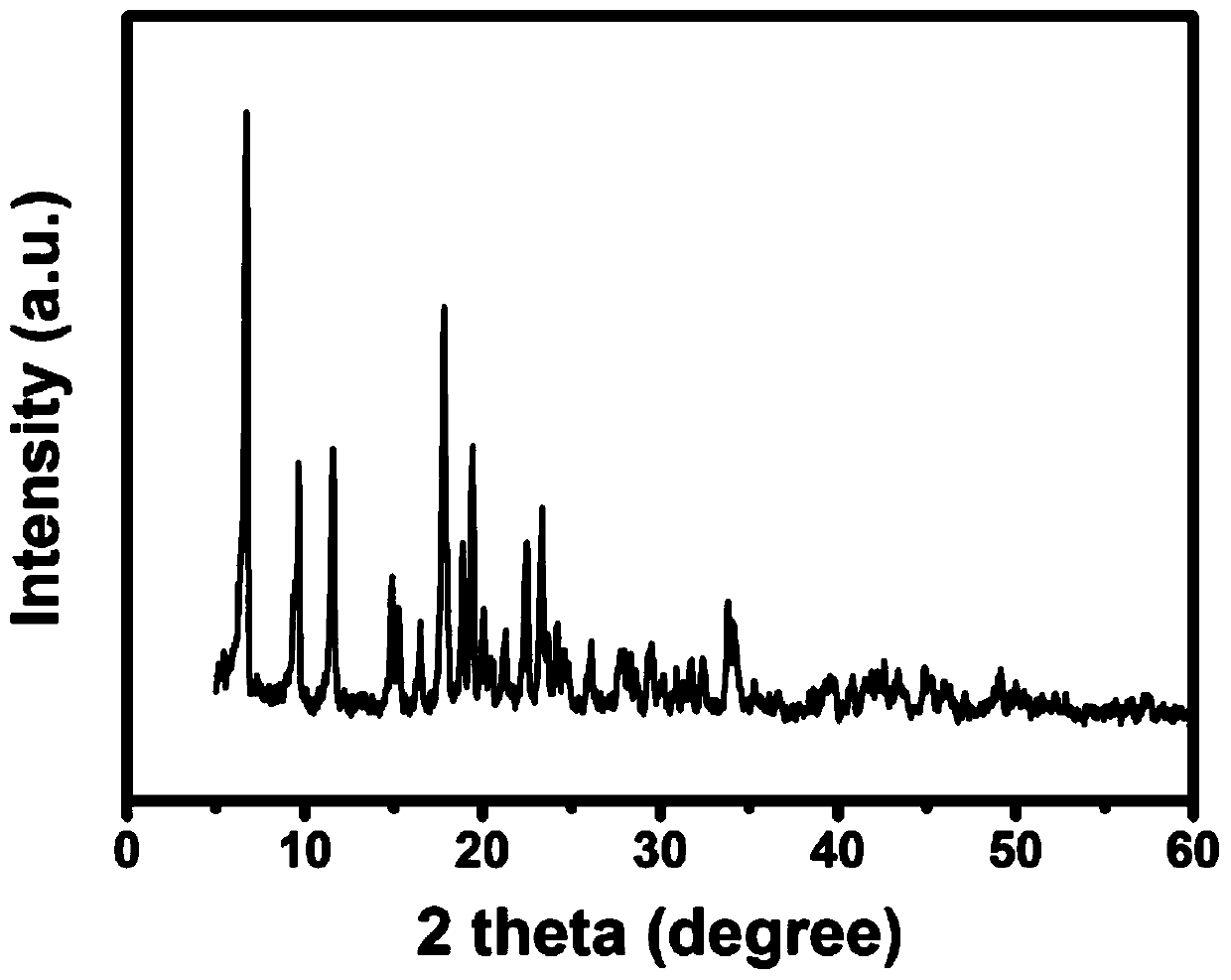

[0035] (3) The product of step 2 is centrifuged and washed with N,N-dimethylformamide and anhydrous methanol (centrifuge speed is 8000r / min, centrifuged for 5min each time), and then dried in a vacuum oven, the temperature of vacuum drying The temperature was 60° C., and the drying time was 12 hours, and the titanium-based metal-organic framework (MIL-125) white crystal powder was taken out.

[0036] (4) Weigh 270 mg of titanium-based metal-organic framework (MIL-125) powder and 30 mg of polyviny...

Embodiment 2

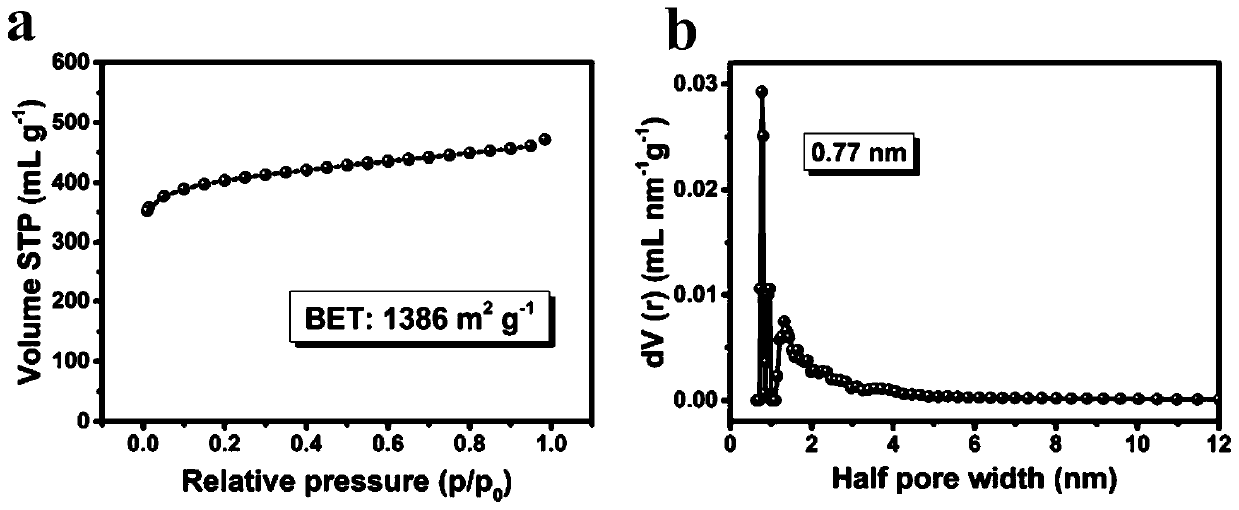

[0047] Nitrogen adsorption / desorption measurements were performed on the titanium-based metal-organic framework (MIL-125) prepared in Example 1, and the specific surface area was calculated using the multipoint Brunauer-Emmett-Teller (BET) method, and the non-local density pan The pore size distribution was calculated by function theory (NLDFT).

Embodiment 3

[0049] Include the following steps:

[0050] (1) Grind 120mg sublimated sulfur, 60mg Ketjen Black and 20mg polyvinylidene fluoride evenly, add 1-methyl-2-pyrrolidone (NMP) solvent, and stir to form a slurry.

[0051] (2) The slurry prepared in step 1 was uniformly coated on the carbon-coated aluminum foil with a coating machine, and then transferred to a vacuum oven for drying. The temperature of the vacuum drying was 60° C., and the drying time was 12 hours.

[0052] (3) Use a punching machine to make the electrode sheet prepared in step 2 into a disc with a diameter of 12 mm as the positive electrode for backup.

[0053] (4) Use two kinds of diaphragms, PP / PE-separator and MIL-125-PP / PE separator, to assemble the model CR2025 button lithium-sulfur battery in an argon-filled glove box (both water and oxygen content are lower than 0.1ppm); , the positive electrode of the battery is the positive electrode sheet in step 3; the electrolyte solution is 1M lithium bis(trifluoromet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com