Preparation method of self-cleaning transmission V belt

A self-cleaning, belt body technology, applied in the field of self-cleaning drive V-belt preparation, can solve problems such as ignoring the use and maintenance of V-belts, lack of in-depth research on V-belts, V-belt performance attenuation, etc., to achieve strength and environmental degradation resistance Improved performance, strengthened V-belt performance, improved molecular cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

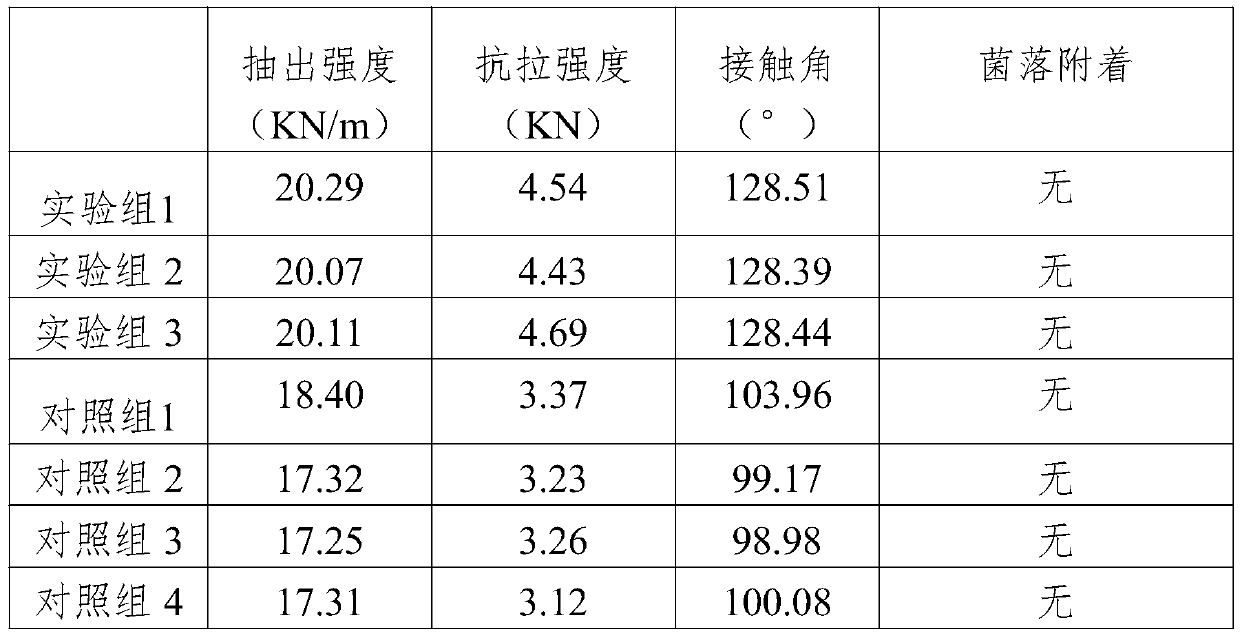

Embodiment 1

[0023] A method for preparing a self-cleaning drive V-belt, comprising:

[0024] (1) Process polyurethane rubber into powder with a particle size of 1mm, mix it with acetone and add it to a sealed container, heat it to 50°C with microwaves, shake it until it dissolves, then lower the temperature to 20°C, and add nano-acicular silicon into the mixing system Limestone powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate were stirred at 40°C until dissolved, and then treated with ultrasonic waves for 20 minutes to obtain mixed slurry A; the mass ratio of the polyurethane rubber to acetone was 1:9 ; The mass ratio of the polyurethane rubber, nano-acicular wollastonite powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate is 10:1:1:0.1;

[0025] (2) Mix dicumyl oxide, fluororubber 26 and mixed slurry A at 80°C, add chromium oxide ceramic fiber after dissolving, raise the temperature of the mixing system to 150°C, stir at a high speed of ...

Embodiment 2

[0030] A method for preparing a self-cleaning drive V-belt, comprising:

[0031] (1) Process polyurethane rubber into powder with a particle size of 3mm, mix it with acetone and add it to a sealed container, heat it to 55°C with microwaves, shake it until it dissolves, then lower the temperature to 30°C, and add nano-acicular silicon into the mixing system Limestone powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate were stirred at 50°C until dissolved, and then treated with ultrasonic waves for 30 minutes to obtain mixed slurry A; the mass ratio of the polyurethane rubber to acetone was 1:13 ; The mass ratio of the polyurethane rubber, nano-acicular wollastonite powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate is 10:1:1:0.1;

[0032] (2) Mix dicumyl oxide, fluororubber 26 and mixed slurry A at 90°C, add chromium oxide ceramic fiber after dissolving, raise the temperature of the mixing system to 200°C, stir at a high speed of...

Embodiment 3

[0037] A method for preparing a self-cleaning drive V-belt, comprising:

[0038] (1) Process polyurethane rubber into powder with a particle size of 2mm, mix it with acetone and add it to a sealed container, heat it to 53°C with microwaves, shake until dissolved, then lower the temperature to 25°C, and add nano-acicular silicon into the mixing system Limestone powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate were stirred at 46°C until dissolved, and then treated with ultrasonic waves for 27 minutes to obtain mixed slurry A; the mass ratio of the polyurethane rubber to acetone was 1:11 ; The mass ratio of the polyurethane rubber, nano-acicular wollastonite powder, nano-montmorillonite powder, and sodium dioctyl succinate sulfonate is 10:1:1:0.1;

[0039] (2) Mix dicumyl oxide, fluororubber 26 and mixed slurry A at 84°C, add chromium oxide ceramic fiber after dissolving, raise the temperature of the mixing system to 160°C, stir at a high speed of 350rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com