Aminated Fe3O4@MCM-41 nanoparticles and application thereof in graphite felt anode for microbial fuel cell

A nanoparticle and amination technology, applied in biochemical fuel cells, battery electrodes, electrochemical biocombination treatment, etc., can solve problems such as poor energy conversion efficiency, low MFC power density, and slow electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

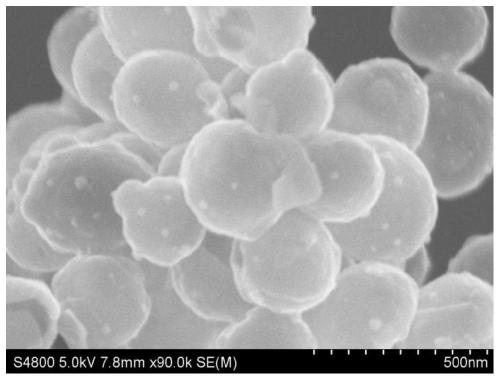

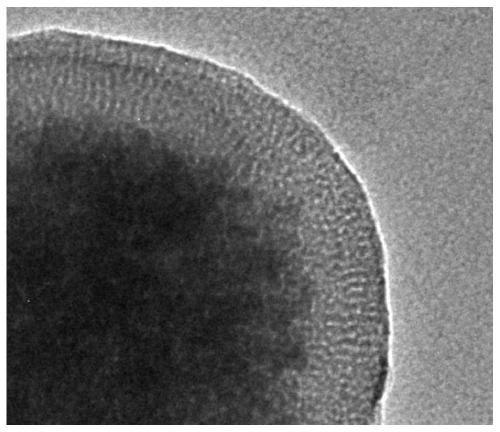

[0038] Example 1, this example provides a method for preparing aminated Fe3O4@MCM-41 nanoparticles

[0039]Ethylene glycol (200 mL), FeCl3·6H2O (6.4 g), SDS (3.0 g) and sodium acetate (16 g) were mixed, stirred at room temperature for 30 minutes, and poured into a Teflon bottle. After heating at 200°C for 8 hours, a solid sample was collected to obtain Fe3O4 particles. These Fe3O4 particles (0.2 g) were then dispersed in ethanol (40 mL), and the particles were dispersed by ultrasonic vibration. The following reagents were added sequentially, including ethanol (40 mL), deionized water (20 mL), concentrated ammonia (1.0 mL) and ethyl orthosilicate TEOS (0.2 g). The cloudy solution was stirred at room temperature for 6 hours, and then the solid product was washed with deionized water to obtain silica cores. Ethanol (60mL), deionized water (80mL), cetyltrimethylammonium bromide CTAB (0.30g), concentrated ammonia (1.0mL) and tetraethyl orthosilicate (TEOS) (0.8g), followed by Th...

Embodiment 2

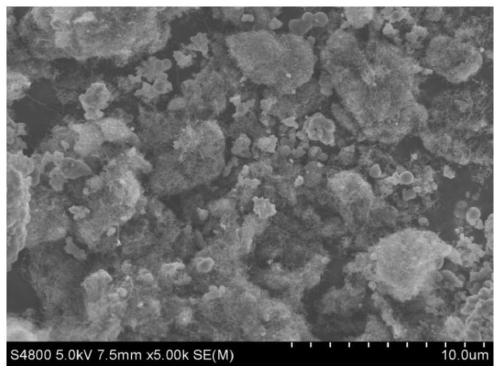

[0042] Example 2 The preparation method of graphite felt anode for microbial battery in this example

[0043] The graphite felt was cut into a rectangle (thickness 2mm) of 1.5cm×1.0cm, and washed with 1mol / L HCl, 1mol / LNaOH, 3% H2O2, acetone, and deionized water at 50°C. Let it dry for later use. Fix the graphite rod on one side of the graphite felt with conductive silver glue, seal and fix it with epoxy resin glue, and dry at room temperature to ensure that the effective area of the graphite felt is 1.0cm×1.0cm.

[0044] Accurately weigh Fe3O4@MCM-41-NH2 and washed and dried MWCNT-COOH according to the mass ratio of 3:7, and grind them in a mortar to mix the two evenly, and due to the hydrogen bond between the amino group and the carboxyl group , the two can be combined into Fe3O4@MCM-41 / MWCNT nanocomposites. According to the proportion of dispersing 10mg of the mixture in 1mL of 1% Nafion / ethanol solution, ultrasonically disperse evenly, drop every 500 μL on 1cm2 graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com