Catalytic cracking catalyst and preparation method and application thereof

A catalytic cracking and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low yield of light fractions and achieve long-term suppression of agglomeration Great effect of improving cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

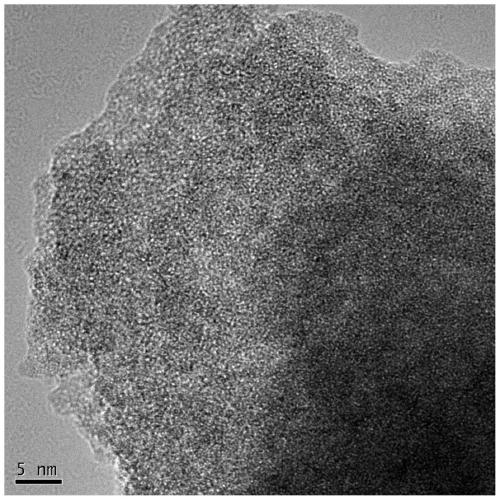

Image

Examples

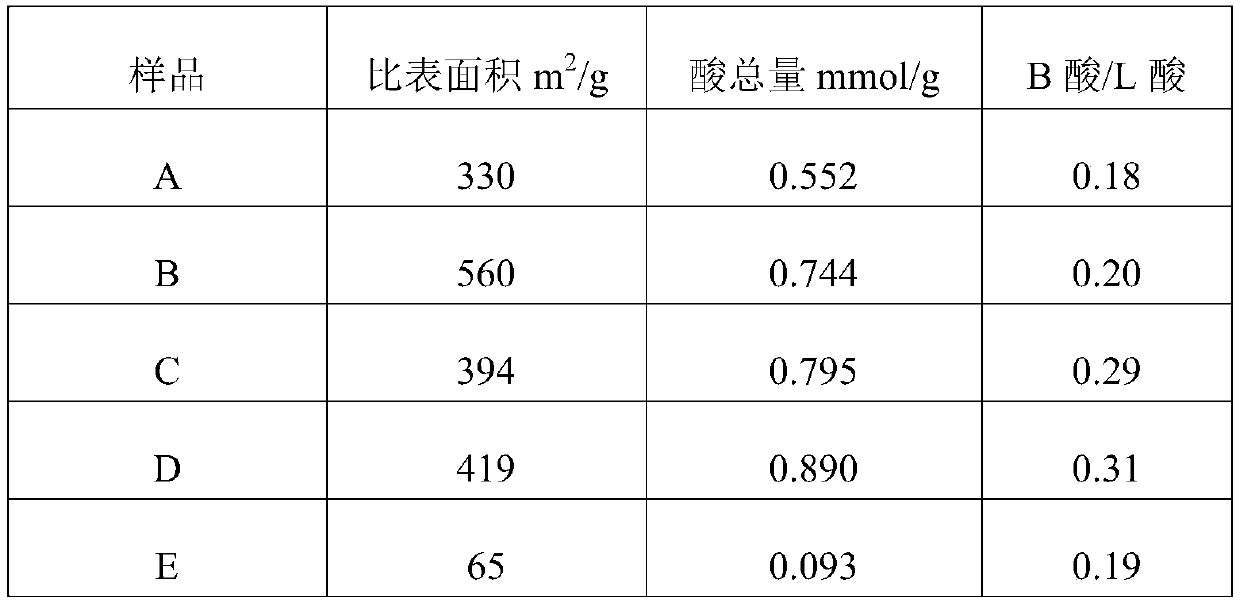

preparation example Construction

[0037] The present invention also provides a kind of preparation method of catalytic cracking catalyst, it is characterized in that, comprises the steps:

[0038] S1. Prepared by mixing alcohols and water at a volume ratio of 1:(0.2-1), and then adding a silicon-based precursor to the mixed solution, wherein the volume ratio of the silicon-based precursor to the mixed solution is 1:5-50, Stir at room temperature to hydrolyze the silicon-based precursor to prepare silica sol. The alcohol is one of methanol, ethanol, ethylene glycol, and isopropanol, and the silicon-based precursor is tetrabutyl orthosilicate, ethyl orthosilicate, methyl orthosilicate, and water glass. A sort of.

[0039] S2. Add the modifier precursor to the silica sol prepared in step S1 in a specific proportion, and then add alkaline substances dropwise to make the pH value in the sol be between 2 and 10, and then move the sol into a hydrothermal kettle to adjust the temperature at 60 to 200 Under the tempe...

Embodiment 1

[0047] This embodiment is used to illustrate the catalytic cracking catalyst preparation method and catalytic cracking catalyst provided by the present invention, specifically as follows:

[0048] S1. Mix isopropanol and water at a volume ratio of 1:1 to prepare a mixed solution, and then add tetraethyl orthosilicate to the mixed solution, wherein the volume ratio of tetraethyl orthosilicate to the mixed solution is 1:5. Stir at room temperature for 2 hours to hydrolyze the silicon-based precursor ethyl orthosilicate to prepare silica sol.

[0049] S2. Add titanium isopropoxide to the above-mentioned silica sol according to the molar ratio of Ti:Si 1:50, add ammonia water dropwise after stirring at room temperature for 0.5 hours, adjust the pH to 7.0, then move the sol into a hydrothermal kettle, The hydrothermal reaction was carried out at ℃ for 20 hours to obtain the intermediate.

[0050] S3. After the temperature of the above-prepared intermediate was lowered to normal te...

Embodiment 2

[0052] This embodiment is used to illustrate the catalytic cracking catalyst preparation method and catalytic cracking catalyst provided by the present invention, specifically as follows:

[0053] S1. Mix ethanol and water at a volume ratio of 1:1 to prepare a mixed solution, and then add orthobutyl silicate to the mixed solution, wherein the volume ratio of orthobutyl silicate to the mixed solution is 1:50. Stir for 2 hours to hydrolyze the silicon-based precursor butyl orthosilicate to prepare silica sol.

[0054] S2. According to the Zr:Si molar ratio of 1:20, take zirconium oxynitrate and add it to the above-mentioned silica sol, stir at room temperature for 0.5 hours, add ammonia water dropwise, adjust the pH to 2.0, then move the sol into a hydrothermal kettle, and heat it at 80°C The hydrothermal reaction was carried out for 24 hours to obtain the intermediate.

[0055] S3. After the temperature of the above-prepared intermediate was lowered to normal temperature, it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com