Gas-solid phase reaction double-noble metal catalyst and preparation method thereof

A noble metal catalyst, gas-solid phase technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst, etc., can solve the problems of complex preparation process, affecting gas mass transfer, low catalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

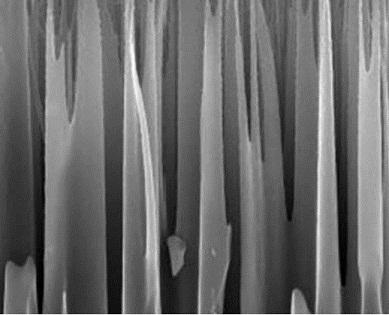

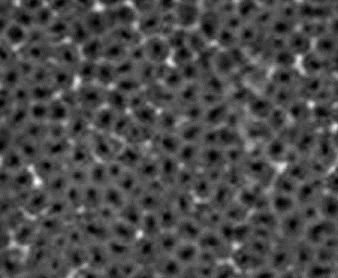

[0058] Silver or silver fluoride / needle-shaped α-alumina catalyst, comprising the following steps:

[0059] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafer to a suitable size, and then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains. The number of cleanings is once, and then soak in 10wt% hydrofluoric acid for 10 minutes to remove The oxide layer was washed with deionized water and dried under an inert atmosphere;

[0060] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:2:4, and the temperature is 30 o C, the time is 1min, and the AgNO3 concentration is preferably controlled to be 2mM;

[0061] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and...

Embodiment 2

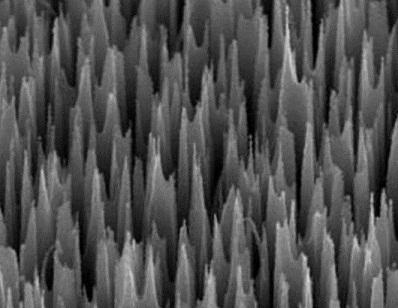

[0069] Silver or silver fluoride / needle-shaped α-alumina catalyst, comprising the following steps:

[0070] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafers to a suitable size, then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains, repeat the cleaning times twice, and then soak in 12.5wt% hydrofluoric acid Remove the oxide layer for 10 minutes, wash with deionized water, and dry under an inert atmosphere;

[0071] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:2.5:6, and the temperature is 32.5 o C, the time is 1.5min, and the AgNO3 concentration is preferably controlled to be 2.5mM;

[0072] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and h...

Embodiment 3

[0080] Silver or silver fluoride / needle-shaped α-alumina catalyst, comprising the following steps:

[0081] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafer to a suitable size, and then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains, repeat the cleaning times 3 times, and then soak in 15wt% hydrofluoric acid for 10 minutes Remove the oxide layer, wash with deionized water, and dry under an inert atmosphere;

[0082] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:3:8, and the temperature is 35 o C, the time is 2min, and the AgNO3 concentration is preferably controlled to be 3mM;

[0083] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com